Zinc y sus aleaciones

Zinc and its alloys are commonly used in precision casting, characterized by good fluidity, a low melting point, and excellent corrosion resistance. Zinc alloys enable precise filling of complex molds during the casting process, making them suitable for parts requiring high precision and excellent surface quality. Zinc alloys are widely used in the electronics, automotive, and consumer goods industries, often in the manufacture of housings, connectors, and auto parts.

In precision casting, zinc alloys are primarily used in die casting and investment casting processes, offering high precision and high production efficiency. Their low melting point helps reduce production costs, and their excellent surface finish properties give them significant advantages in high-volume production.

In precision casting, zinc alloys are primarily used in die casting and investment casting processes, offering high precision and high production efficiency. Their low melting point helps reduce production costs, and their excellent surface finish properties give them significant advantages in high-volume production.

Common Material Grades of Zinc And Its Alloys

| Grado de aleación | Nombre de la aleación | Propiedades del material | Main Application Industries | Widget de muestra |

| ZL2 | Zl2 Alloy | Excellent castability, good strength and hardness, good corrosion resistance | Automobile, electronics, electrical, precision casting | Electronic component housings, auto parts |

| ZL3 | Zl3 Alloy | Excellent castability and good mechanical properties with medium strength | Precision casting, electronic device manufacturing | Precision gears and mechanical parts |

| ZL5 | Zl5 Alloy | High strength, strong wear resistance and good corrosion resistance | Aerospace, automotive parts | High-strength frames, automobile engine casings |

| ZL8 | Zl8 Alloy | Low casting temperature, good fluidity and surface finish | Precision casting, automobiles, electronics | Precision casting of power tool housings and transmission system components |

| ZA8 | ZA8 Alloy | High strength, good corrosion resistance, suitable for high pressure casting | Automotive, electrical, aerospace | Electronic connectors, high-pressure casting parts |

| ZL27 | Zl27 Alloy | Excellent strength, corrosion resistance and wear resistance | Aerospace, automotive | High-strength automobile engine parts |

| ZD9 | ZD9 Alloy | Excellent corrosion resistance and strength, good heat treatment | Marine engineering, precision casting | Ship parts, marine equipment housings |

| ZD8 | ZD8 Alloy | Good casting properties, high tensile strength and ductility | Precision casting, electronics, instruments | Electronic product housings, medical equipment components |

| ZL13 | Zl13 Alloy | Good castability and corrosion resistance, high strength and hardness | Aerospace, automotive, precision casting | Aviation parts, automotive precision casting parts |

Zinc and Its Alloy Casting Process

Fundición de inversión

Aplicabilidad: Suitable for casting zinc and its alloys, but is generally used for precision castings, especially when high precision and complex geometry are required. Investment casting can achieve very detailed designs, including complex internal cavities and precise surface finishes.

Ventajas:

· High-precision, low-volume products: Small precision parts in the aviation, automotive, and medical device industries.

· Excellent surface finish: Suitable for zinc alloy parts with complex shapes, thin walls, and high wear resistance.

· Rapid development and customization: Customized products requiring fast delivery.

· High-precision, low-volume products: Small precision parts in the aviation, automotive, and medical device industries.

· Excellent surface finish: Suitable for zinc alloy parts with complex shapes, thin walls, and high wear resistance.

· Rapid development and customization: Customized products requiring fast delivery.

Fundición en arena

Aplicabilidad: Sand casting is a traditional and widely used casting process suitable for zinc alloy casting, especially in the production of larger castings. Sand casting molds are relatively low cost, suitable for small or medium batch production, and can produce larger castings.

Ventajas:

· Medium-sized, non-precision castings: Suitable for larger, simple-shaped parts such as automotive components and electrical enclosures.

· Lower costs: Suitable for high-volume production where cost-effective products are required, especially in high-volume production.

· Medium-sized, non-precision castings: Suitable for larger, simple-shaped parts such as automotive components and electrical enclosures.

· Lower costs: Suitable for high-volume production where cost-effective products are required, especially in high-volume production.

Fundición a presión

Aplicabilidad: Die casting is very suitable for the efficient large-scale production of zinc and its alloys, especially for the mass production of high-precision and thin-walled castings. Zinc alloys have excellent fluidity and low melting points during the die casting process, making them very suitable for the rapid production of high-quality castings.

Ventajas:

· Large-Scale Production and Precision Castings: Suitable for mass production of high-precision, complex-shaped castings, such as electronic device housings, home appliance components, and automotive parts.

· High Production Efficiency: Suitable for industries with demanding lead times, such as consumer electronics, automotive, and industrial equipment.

· Large-Scale Production and Precision Castings: Suitable for mass production of high-precision, complex-shaped castings, such as electronic device housings, home appliance components, and automotive parts.

· High Production Efficiency: Suitable for industries with demanding lead times, such as consumer electronics, automotive, and industrial equipment.

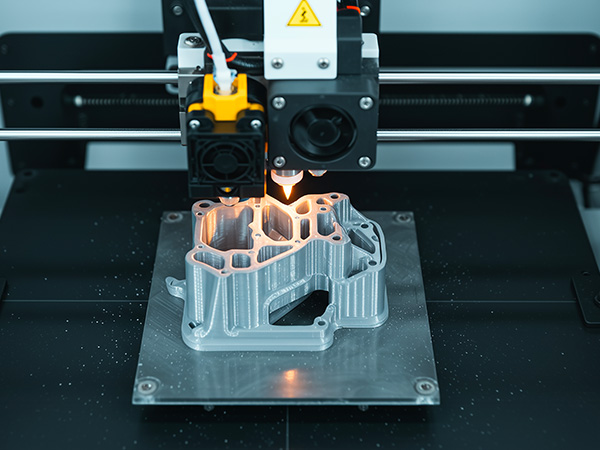

Impresión 3D

Aplicabilidad: 3D printing technology is suitable for small-batch, high-complexity, and rapidly developed castings, and is particularly suitable for customization and prototyping. Although 3D printing casting is still in its development stage, in some cases, it can be used to produce complex zinc alloy parts.

Ventajas:

· Small-batch customization and rapid prototyping: Zinc alloy parts that require rapid production, such as prototype testing and design verification.

· Complex shapes and innovative designs: These applications require complex castings, especially those requiring rapid modification and verification during the design phase.

· Small-batch customization and rapid prototyping: Zinc alloy parts that require rapid production, such as prototype testing and design verification.

· Complex shapes and innovative designs: These applications require complex castings, especially those requiring rapid modification and verification during the design phase.

Comience su proyecto con Leierwo

1. Envíe su consulta

Envíe sus dibujos CAD y archivos 3D por correo electrónico, especificando el grado del material, la cantidad del pedido, el acabado de la superficie o cualquier otro detalle relevante.

2. Cálculo de costes

En cuanto recibamos su diseño, nuestro equipo de ingenieros evaluará detenidamente los planos y calculará el precio en función de los costes de producción reales lo antes posible.

3. Inicio de la producción

Una vez aprobado el precio, nuestro equipo de producción preparará los materiales y programará la producción con prontitud.Leierwo siempre garantiza la entrega a tiempo.

4. Organizar la entrega

Una vez finalizada la producción, le proporcionaremos los detalles del embalaje y organizaremos el envío por mar o aire. Todos los pedidos se pueden enviar a cualquier parte del mundo.

PREGUNTAS FRECUENTES

P1. ¿Es usted una empresa comercial o un fabricante?

P2. ¿Pueden cotizar basándose en dibujos 3D?

P3. ¿Cómo se gestionan las RFQ (solicitudes de cotización)?

P4. ¿Cuál es su plazo de entrega típico?

P5. ¿Ofrecen muestras? ¿Son gratuitas?

P6. ¿Qué métodos de pago aceptan?

P7. ¿Cómo se garantiza el control de calidad?

P8. ¿Sus productos vienen con garantía?

P9. ¿Cómo ve su relación con los clientes?