¿Qué es el acero al carbono 1035? Una guía completa

Tabla de contenido

Introducción

Steel, one of the most versatile materials used in manufacturing and construction, comes in various grades depending on its composition and intended application. Acero al carbono 1035 is one such grade that offers a balance of strength and machinability. It is often chosen for applications that require medium-strength steel, offering good hardness when heat-treated and the ability to undergo processes like induction and flame hardening.

This guide will dive deep into Acero al carbono 1035, exploring its composition, properties, advantages, and common applications. We will also address key considerations for using 1035 Carbon Steel and compare it to other similar grades. By the end of this post, you’ll have a better understanding of whether 1035 Carbon Steel is the right choice for your project.

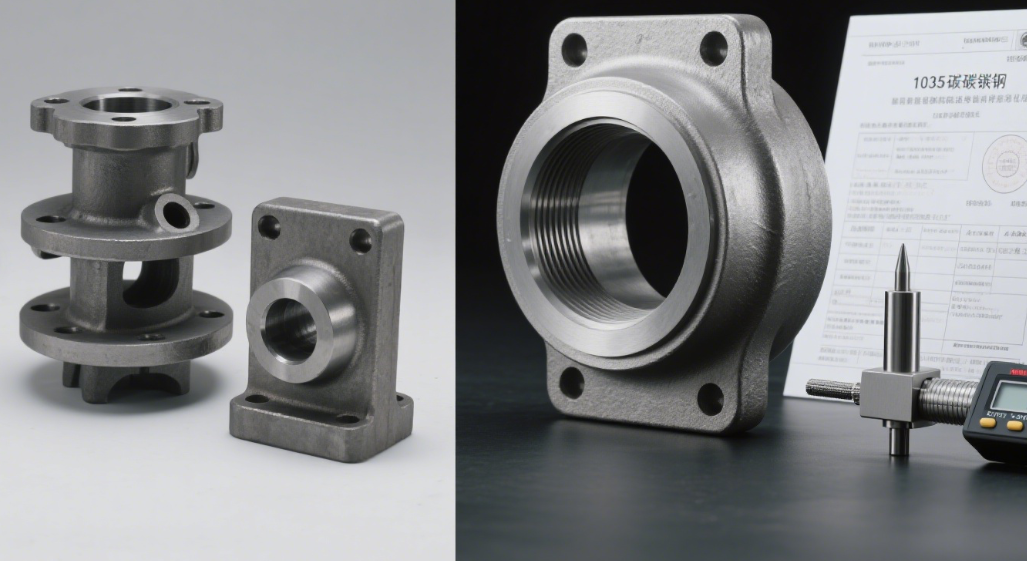

What is 1035 Carbon Steel?

Acero al carbono 1035 is a medium-carbon steel with carbon content ranging from approximately 0.30% to 0.40%. It is classified as a low alloy steel, known for its good balance of strength, toughness, and wear resistance. This grade is generally used when hardness is required without compromising ductility and toughness.

Características principales

- Carbon Content: 0.35% carbon, which makes it suitable for induction and flame hardening.

- Heat Treatment: Can be heat-treated for improved hardness and strength.

- Machinability: Offers good machinability, making it a great choice for manufacturing complex parts that require precision.

Chemical Composition of 1035 Steel

| Elemento | Percentage (%) |

|---|---|

| Carbono (C) | 0.35 |

| Manganeso (Mn) | 0.60 – 0.90 |

| Fósforo (P) | 0.04 max |

| Azufre (S) | 0.05 max |

| Silicio (Si) | 0.10 – 0.35 |

| Hierro (Fe) | Balance |

Properties of Acero al carbono 1035

Propiedades mecánicas

- Tensile Strength: Acero al carbono 1035 typically has a tensile strength range of around 470 to 700 MPa (megapascals). This makes it suitable for moderately stressed applications but not ideal for extremely high-stress environments.

- Hardness: It exhibits a Rockwell hardness of approximately 60-65 HRC after proper heat treatment. This makes it hard enough for various machining processes and ideal for creating parts like gears and couplings.

- Ductility and Toughness: Despite its hardness, Acero al carbono 1035 maintains a good level of ductility, allowing it to withstand shocks or impact loads. This makes it a versatile option for components that may be subject to varying stress conditions.

- Resistencia a la corrosión: As a low-alloy steel, it doesn’t have the same level of corrosion resistance as stainless steel, so additional coatings or treatment may be necessary for specific applications.

Physical Properties

- Density: Approximately 7.85 g/cm³, which is typical for carbon steel.

- Melting Point: Around 1,500°C (2,732°F).

Applications of 1035 Carbon Steel

Due to its properties, Acero al carbono 1035 is used in a wide range of applications across various industries. It is particularly favored in manufacturing processes that require forged parts or components subjected to mechanical stresses.

Aplicaciones comunes

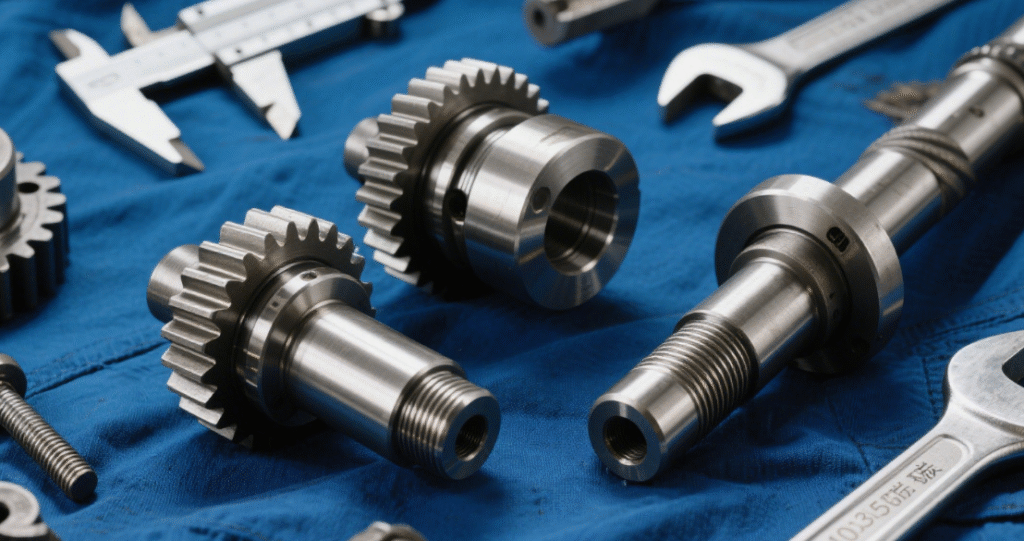

- Forged Parts: 1035 Carbon Steel is ideal for forging operations, including gears, shafts, and axles.

- Automotive Industry: It is commonly used for producing connecting rods, couplings, and other components that require both strength and machinability.

- Industrial Machinery: This steel grade is used in the manufacture of tools, dies, and machinery components.

- Agriculture and Construction Equipment: Due to its durability, 1035 Carbon Steel is found in parts like axles, shafts, and structural components used in equipment.

Advantages in Applications

- Good Strength and Toughness: Makes it ideal for components that must withstand moderate impact.

- Versatile for Heat Treatment: It responds well to induction and flame hardening, allowing for increased hardness without sacrificing ductility.

- Rentable: Compared to higher alloy steels, 1035 Carbon Steel is relatively low-cost, making it suitable for budget-conscious applications without compromising on performance.

1035 Carbon Steel vs. Other Carbon Steels

When choosing Acero al carbono 1035 for your project, it is important to understand how it compares to other grades of carbon steel. Here’s a brief comparison of Acero al carbono 1035 con Acero al carbono 1018 y Acero al carbono 1045, two other commonly used grades.

| Propiedad | Acero al carbono 1035 | Acero al carbono 1018 | Acero al carbono 1045 |

|---|---|---|---|

| Contenido de carbono | 0.35% | 0.18% | 0.45% |

| Resistencia a la tracción | 470 – 700 MPa | 440 – 570 MPa | 600 – 850 MPa |

| Hardness | 60-65 HRC | 50-60 HRC | 65-75 HRC |

| Aplicaciones | Gears, shafts, axles | Light-duty machinery | High-stress components |

| Tratamiento térmico | Induction, flame hardening | Mild heat treatment | Can be hardened to a higher level |

- Acero al carbono 1018 has lower carbon content and is ideal for low-strength applications but doesn’t have the same hardness potential as 1035.

- Acero al carbono 1045, with higher carbon content, offers greater tensile strength and hardness but is more difficult to machine than 1035.

How to Heat Treat 1035 Carbon Steel

Heat treating is a crucial process that enhances the properties of 1035 Steel, particularly its hardness. Here’s a quick overview of how to heat treat this grade of steel:

- Austenitizing: Heat the steel to a temperature between 800-850°C (1,472-1,562°F).

- Quenching: Rapidly cool the steel in water or oil to harden it.

- Tempering: Reheat to a lower temperature (around 300-400°C or 572-752°F) to reduce brittleness and achieve desired hardness.

This heat treatment process allows Acero al carbono 1035 to become harder, making it suitable for parts like gears, axles, and other components subject to wear and tear.

Conclusión

Acero al carbono 1035 is a versatile and cost-effective material that offers a balance of strength, toughness, and machinability. With a carbon content of 0.35%, it is ideal for applications that require moderate strength and hardness, such as gears, axles, and shafts. Its ability to undergo induction and flame hardening makes it an excellent choice for various industrial uses.

By understanding its properties, advantages, and best applications, you can make an informed decision about whether Acero al carbono 1035 is the right material for your project. Whether you’re working in automotive, industrial machinery, or construction, Acero al carbono 1035 offers the right combination of performance and cost-efficiency for many manufacturing needs.

PREGUNTAS FRECUENTES

1. What is the main use of 1035 Steel?

Acero al carbono 1035 is primarily used for manufacturing forged parts, connecting rods, gears, couplings, and other components that require medium-strength steel. It is commonly used in automotive, agricultural, and industrial machinery applications.

2. What is the difference between 1035 and 1045 Carbon Steel?

The main difference is the carbon content. Acero al carbono 1045 has a higher carbon content, making it stronger and harder but less machinable than Acero al carbono 1035. 1035 is more versatile for applications requiring moderate strength and machinability.

3. Is 1035 Steel corrosion-resistant?

No, 1035 Steel does not offer the same corrosion resistance as stainless steel. For applications exposed to harsh environments, additional coatings or treatments are necessary to protect against rust and corrosion.

4. Can 1035 Steel be welded?

Sí, 1035 Steel can be welded, but care must be taken during the welding process to avoid cracks. Pre-heating and post-weld heat treatment may be required to ensure a strong weld.

5. How does 1035 Steel compare to 1018?

1035 Steel has a higher carbon content than 1018, which gives it more hardness and strength after heat treatment. It is better suited for applications where higher strength is required, while 1018 is used for lower-strength applications.

Manténgase conectado con nosotros

¡Gracias por leer! Esperamos que este blog te haya brindado información valiosa e inspiración sobre techos con paneles acústicos. Si disfrutaste del contenido y quieres estar al día de las últimas tendencias, consejos y novedades, nos encantaría conectar contigo en redes sociales.

📘 Síguenos en Facebook: Shanghai Leierwo Industria Comercio Co., Ltd.

Únase a nuestra creciente comunidad donde compartimos consejos de expertos, aspectos destacados de los productos y debates interactivos con profesionales y entusiastas del diseño de todo el mundo.

Sigamos conversando, ¡nos vemos allí!

Categorías de productos

- Piezas de válvulas

- Piezas de la bomba de agua

- Piezas de la caja de cojinetes

- Piezas de fundición a presión

- Productos para bombas de acero inoxidable

- Productos para bombas de hierro fundido

- Piezas de válvulas para automóviles

- Recambios para automóviles

- Piezas de válvulas para uso civil

- Piezas de bomba de vacío KF