Níquel y sus aleaciones

Nickel and its alloys are materials with excellent corrosion resistance, high-temperature resistance, and strength, making them widely used in precision casting. Nickel alloys offer excellent oxidation resistance, wear resistance, and superior mechanical properties, enabling stable operation in extreme environments. Therefore, they are often used in the manufacture of components requiring high performance and reliability, particularly in the aerospace, chemical equipment, and energy sectors.

In precision casting, nickel and its alloys are primarily used to produce critical components subjected to high-temperature environments, such as turbine blades, gas turbine components, and engine parts. Common casting processes include investment casting and sand casting, both of which ensure the high precision and complex shapes of nickel alloy components. The key advantages of nickel alloys include their exceptional high-temperature resistance, strength, and excellent corrosion resistance, making them particularly suitable for high-end applications requiring long-term exposure to high temperatures and chemical corrosion.

In precision casting, nickel and its alloys are primarily used to produce critical components subjected to high-temperature environments, such as turbine blades, gas turbine components, and engine parts. Common casting processes include investment casting and sand casting, both of which ensure the high precision and complex shapes of nickel alloy components. The key advantages of nickel alloys include their exceptional high-temperature resistance, strength, and excellent corrosion resistance, making them particularly suitable for high-end applications requiring long-term exposure to high temperatures and chemical corrosion.

Common Material Grades of Nickel and Its Alloys

| Grado de aleación | Nombre de la aleación | Propiedades del material | Industria de aplicaciones | Widget de muestra |

| Nickel Alloy | Inconel 625 | High strength, corrosion resistance, high temperature resistance, and resistance to oxidation and carbonization | Aerospace, chemical industry, energy, precision casting | Jet engine turbine blades, chemical reactors, heat exchangers |

| Inconel 718 | Good high temperature strength and good corrosion resistance, suitable for applications in high temperature environments | Aerospace, energy, precision casting, automobile manufacturing | Turbine blades, engine components, gas turbine blades | |

| Inconel 718 | Excellent corrosion resistance and oxidation resistance, good heat resistance | Chemical, petroleum, energy, precision casting | Reactors, heat exchangers, boiler components, heating furnace components | |

| High Temperature Nickel Alloys | Monel 400 | Good corrosion resistance and high temperature resistance, especially suitable for seawater environment | Marine engineering, chemical industry, aerospace, precision casting | Ship equipment, seawater pipelines, chemical reactors, pump bodies |

| Haynes 230 | Has good high temperature stability and oxidation resistance, can work under extreme high temperature | Aeroespacial, energía, fundición de precisión | High-temperature alloy turbine blades, combustors, and aircraft engine components | |

| Corrosion-Resistant Nickel Alloy | Monel K-500 | It has good corrosion resistance and high strength, especially in seawater and various chemical environments | Petroleum, marine engineering, chemical industry, precision casting | Submarine components, ship pumps, offshore platforms, pipeline connectors |

| Iron-Nickel Alloy | Invar 36 | With extremely low thermal expansion coefficient, it is widely used in high-precision measurement and control equipment | Precision instruments, aerospace, automobiles, precision casting | Thermometers, barometers, laser measuring equipment, aviation components |

| Kovar | It has a thermal expansion coefficient close to that of steel and is often used for sealing with glass | Electronics, optical equipment, precision casting, medical devices | Electronic component packaging, vacuum packaging, optical devices, medical implants | |

| Cobalt-Nickel Alloy | Stellite 6B | Excellent wear resistance, corrosion resistance, good oxidation resistance and high temperature performance | Aerospace, precision casting, automotive, energy | Nozzles, gas turbine blades, valve seats, wear parts |

| Deloro Stellite | Extremely strong wear resistance and corrosion resistance, outstanding high temperature resistance | Mining, petroleum, energy, precision casting | Wear-resistant castings, valve seats, cutting tools, gas turbine components |

Ductile Iron Casting Process

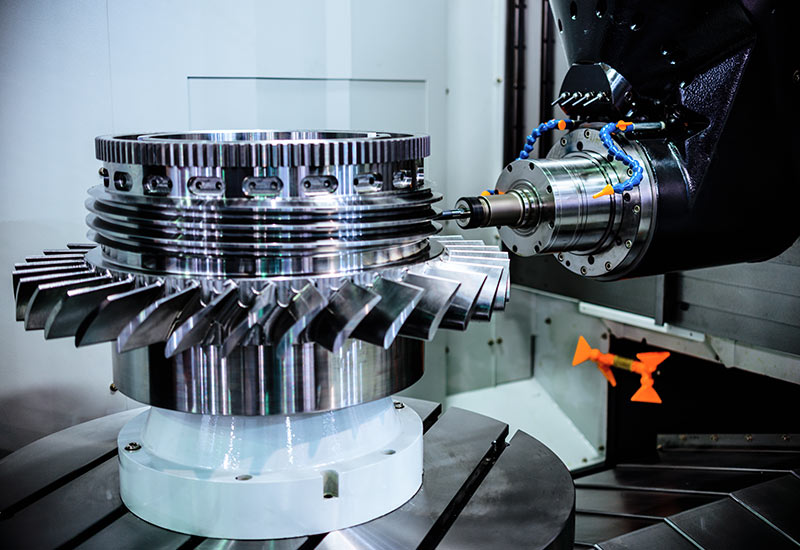

Fundición de inversión

Aleaciones aplicables: Inconel 625, Inconel 718, Monel 400, Stellite 6B and other nickel-based high-temperature alloys, suitable for high-performance, complex-shaped castings.

Características: Fundición de alta precisión: La fundición de inversión ofrece una precisión excepcionalmente alta, lo que la hace adecuada para geometrías complejas.

Excelente calidad de superficie: Adecuado para piezas fundidas que requieren tratamientos superficiales delicados, minimizando el mecanizado posterior.

Adaptabilidad a formas complejas: especialmente adecuado para piezas fundidas con estructuras internas complejas, como álabes de turbinas y componentes de motores.

Excelente calidad de superficie: Adecuado para piezas fundidas que requieren tratamientos superficiales delicados, minimizando el mecanizado posterior.

Adaptabilidad a formas complejas: especialmente adecuado para piezas fundidas con estructuras internas complejas, como álabes de turbinas y componentes de motores.

Aplicaciones: Aeroespacial: Álabes de turbinas y componentes de cámara de combustión.

Energía: Componentes de aleación de alta temperatura y piezas de reactores.

Instrumentos de precisión: Componentes que requieren alta precisión y resistencia.

Energía: Componentes de aleación de alta temperatura y piezas de reactores.

Instrumentos de precisión: Componentes que requieren alta precisión y resistencia.

Si necesita producir componentes de aleación de alta temperatura o formas complejas, la fundición de inversión es la opción ideal.

Fundición en arena

Aleaciones aplicables: Nickel alloys such as Incoloy 800 and Monel 400, suitable for medium-complexity castings produced in large quantities.

Características: Low Cost: Sand casting is suitable for large-scale production and is less expensive than other precision casting processes.

Wide Size Range: It can cast components ranging from small to large, meeting various scale requirements.

Material Adaptability: It can cast various nickel alloys, including corrosion-resistant alloys, relatively smoothly.

Wide Size Range: It can cast components ranging from small to large, meeting various scale requirements.

Material Adaptability: It can cast various nickel alloys, including corrosion-resistant alloys, relatively smoothly.

Applicable Applications: Chemical and Energy: Chemical equipment, heat exchangers, and boiler components.

Marine Engineering: Offshore platform components, pump bodies, etc.

Heavy Machinery: Large equipment parts.

Marine Engineering: Offshore platform components, pump bodies, etc.

Heavy Machinery: Large equipment parts.

If your production needs are large quantities of corrosion-resistant or high-temperature resistant castings, sand casting can provide an efficient and cost-competitive production method.

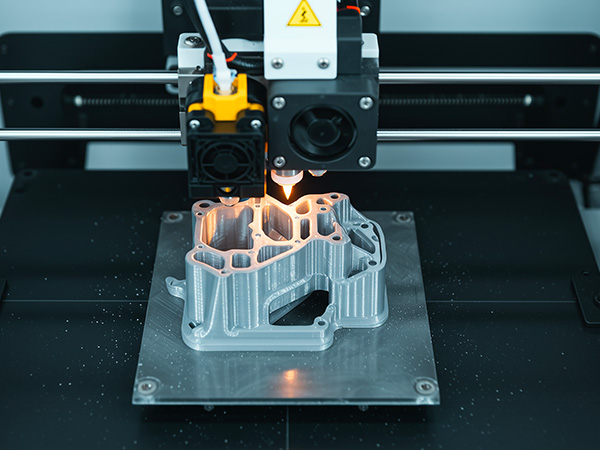

Impresión 3D

Aleaciones aplicables: Nickel-based alloys such as Inconel 625, Inconel 718, and Monel 400, especially suitable for small batches or prototype testing.

Características: Design Flexibility: Print directly from CAD models, eliminating the need for complex mold manufacturing, making it suitable for designing innovative and complex parts.

Wide Size Range: Capable of casting components ranging from small to large, meeting diverse scale requirements.

Precision Casting: Capable of producing complex geometries and internal structures with high precision.

Wide Size Range: Capable of casting components ranging from small to large, meeting diverse scale requirements.

Precision Casting: Capable of producing complex geometries and internal structures with high precision.

Applicable Applications: Aerospace, Automotive: Engine components, heat exchangers, cooling systems, etc.

Precision Instruments: High-precision sensors, structural components, etc.

Rapid Prototyping and Small-Batch Customization: Suitable for testing and new product development.

Precision Instruments: High-precision sensors, structural components, etc.

Rapid Prototyping and Small-Batch Customization: Suitable for testing and new product development.

If your needs are low-volume production or prototype testing, 3D printing provides a fast way to verify and produce designs, making it ideal for innovative products and short cycle times.

Soldadura

Nickel-based alloys such as Inconel 625, Inconel 718, and Monel K-500 are particularly suitable for more complex assembly and repair work.

Características: High-strength connections: Welding multiple nickel alloy components creates stronger parts than traditional casting.

Suitable for repair and custom production: Suitable for welding reinforcement or repair of existing components.

High-temperature and corrosion resistance: Welded joints perform well in high-temperature and high-pressure environments.

Suitable for repair and custom production: Suitable for welding reinforcement or repair of existing components.

High-temperature and corrosion resistance: Welded joints perform well in high-temperature and high-pressure environments.

Aplicaciones: Aerospace and Energy: Welding and repair of high-temperature components, such as gas turbine blades.

Heavy Machinery and Petroleum Industries: Welding and strengthening equipment, particularly pressure vessels and piping components.

Heavy Machinery and Petroleum Industries: Welding and strengthening equipment, particularly pressure vessels and piping components.

Whether your needs require custom production, repair of existing components, or adding new features to existing designs, welding processes offer flexible solutions.

Comience su proyecto con Leierwo

1. Envíe su consulta

Envíe sus dibujos CAD y archivos 3D por correo electrónico, especificando el grado del material, la cantidad del pedido, el acabado de la superficie o cualquier otro detalle relevante.

2. Cálculo de costes

En cuanto recibamos su diseño, nuestro equipo de ingenieros evaluará detenidamente los planos y calculará el precio en función de los costes de producción reales lo antes posible.

3. Inicio de la producción

Una vez aprobado el precio, nuestro equipo de producción preparará los materiales y programará la producción con prontitud.Leierwo siempre garantiza la entrega a tiempo.

4. Organizar la entrega

Una vez finalizada la producción, le proporcionaremos los detalles del embalaje y organizaremos el envío por mar o aire. Todos los pedidos se pueden enviar a cualquier parte del mundo.

PREGUNTAS FRECUENTES

P1. ¿Es usted una empresa comercial o un fabricante?

P2. ¿Pueden cotizar basándose en dibujos 3D?

P3. ¿Cómo se gestionan las RFQ (solicitudes de cotización)?

P4. ¿Cuál es su plazo de entrega típico?

P5. ¿Ofrecen muestras? ¿Son gratuitas?

P6. ¿Qué métodos de pago aceptan?

P7. ¿Cómo se garantiza el control de calidad?

P8. ¿Sus productos vienen con garantía?

P9. ¿Cómo ve su relación con los clientes?