Hierro fundido versus acero al carbono: dos desafíos importantes. ¡La selección inteligente es clave!

Tabla de contenido

Introducción

In the vast landscape of industrial manufacturing, choosing the right material is paramount to a product’s success, performance, and longevity. Among the most common and versatile ferrous alloys are cast iron and carbon steel. While both are foundational to countless industries, their distinct properties and limitations present significant challenges for engineers and manufacturers. Understanding the fundamental differences between cast iron and carbon steel is not merely an academic exercise; it’s a critical strategic decision that directly impacts functionality, cost, and safety. This blog post aims to dissect the core challenges associated with these materials and provide a comprehensive guide to making smart material selections.

We will delve into the critical mechanical properties that differentiate cast iron and carbon steel, explore their suitability for various demanding applications, and highlight the manufacturing processes that optimize their use. By the end, B2B buyers will gain invaluable insights into making informed decisions that lead to superior product outcomes and operational efficiency. The goal is to provide ideal materials to optimize products and meet the most demanding global application requirements.

Understanding the Fundamentals: Cast Iron vs Carbon Steel

The primary distinction between cast iron and carbon steel lies in their carbon content, which profoundly influences their microstructure and, consequently, their mechanical properties. This fundamental difference shapes their applicability across various industries, from automotive manufacturing to valve casting and pump manufacturing.

The Core Difference: Carbon Content

Carbon steel is an iron-based alloy with a carbon content typically ranging from 0.05% to 2.0%. The concentration of carbon is a critical determinant of its properties; increasing carbon generally enhances strength but reduces plasticity and toughness. This characteristic enables carbon steel to perform exceptionally well in harsh environments involving high pressure and high temperature.

In contrast, cast iron is also an iron-carbon alloy, but its carbon content generally exceeds 2%, often ranging from 2% to 4%. This higher carbon concentration results in a fundamentally different microstructure. The carbon in cast iron primarily exists as graphite, which significantly impacts its mechanical behavior.

Exploring Cast Iron

Cast iron’s unique properties stem largely from the presence and morphology of graphite within its matrix. This graphite often appears in flake form in grey cast iron, cutting through the metallic matrix and reducing tensile strength and plasticity. However, graphite imparts excellent wear resistance, vibration damping, and superior castability, making it ideal for intricate shapes. Cast iron also boasts high compressive strength.

Different types of cast iron are categorized by their graphite morphology:

• Grey Cast Iron: Contains flake graphite, offering good damping properties and suitability for complex shapes like machine tool beds and engine blocks.

• Ductile Iron (Nodular Cast Iron): Produced by treating molten grey cast iron to form spherical graphite, which significantly improves strength, toughness, and plasticity compared to grey cast iron.

• Malleable Cast Iron: Obtained by annealing white cast iron, resulting in flocculent (clump-like) graphite, providing uniform properties, wear resistance, good plasticity, and toughness.

• White Cast Iron: Characterized by carbon existing as iron carbide (cementite), making it extremely hard and brittle.

• Alloy Cast Iron: Contains additional alloying elements like silicon, manganese, nickel, chromium, molybdenum, aluminum, copper, boron, and vanadium to achieve specific properties such as heat resistance, wear resistance, or corrosion resistance.

These variations mean that while cast iron is generally known for its rigidity and brittleness, specific types like ductile iron offer enhanced mechanical properties, making them suitable for a broader range of applications.

Exploring Acero carbono

Carbon steel is broadly categorized by its carbon content into low, medium, and high carbon steel, as well as structural, tool, and free-cutting types. As carbon content increases, so does strength and hardness, though often at the expense of ductility. Despite this, carbon steel generally possesses high strength, plasticity, and toughness. The ability to form various solid solutions and phases like ferrite and austenite through alloying and heat treatment further allows for optimization of its properties.

Low alloy steels, which contain small amounts (generally less than 5%) of alloying elements, are particularly noteworthy. They offer superior strength, toughness, and corrosion resistance compared to plain carbon steel. Pearlitic heat-resistant steels, for instance, maintain stable mechanical properties and oxidation resistance at temperatures up to 600-650°C, making them critical for boiler superheaters and steam pipelines. These materials are vital for high-performance applications in industries requiring stringent performance, consistency, and quality control, such as automotive, valve, and pump manufacturing.

Major Challenge 1: Brittleness and Impact Resistance

One of the most significant challenges when selecting between these materials is managing their inherent differences in brittleness and impact resistance. This difference can be a deal-breaker for applications involving dynamic loads or sudden stresses.

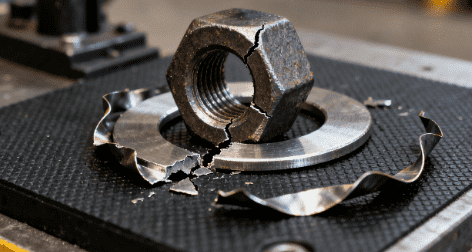

Cast Iron’s Achilles’ Heel: High Impact Loads

Cast iron is notoriously known for its rigidity and high brittleness, particularly grey cast iron, due to the flake graphite microstructure. This makes it susceptible to catastrophic failure under high impact loads or tensile stresses. The graphite acts as internal notches, reducing the material’s ability to deform plastically before fracture. For instance, applications like railway vehicle components that experience significant impact are often ill-suited for traditional cast iron, where the material’s lack of toughness could lead to dangerous failures. This brittle nature necessitates careful design and application constraints, typically limiting cast iron to static or low-impact scenarios where its compressive strength and damping properties can be fully utilized.

Acero carbono‘s Strength: Ductility and Toughness

In stark contrast, carbon steel exhibits significantly better plasticity and toughness compared to cast iron. This superior ductility allows carbon steel to absorb energy and deform before fracturing, making it highly resistant to impact loads and fatigue. This makes carbon steel the material of choice for components subjected to heavy loads and impacts, such as rolling mill frames, hydraulic press bases, and railway vehicle parts like bolsters and side frames.

The ability of carbon steel to “bend but not break” under stress is a critical advantage in dynamic applications. Furthermore, low alloy steels enhance these properties, providing even greater impact toughness and extended service life for parts. This resilience under stress is a primary reason why carbon steel and alloy steel are used in automotive components like engine mounts, transmission housings, and brake system parts, where performance, consistency, and quality control are paramount.

Major Challenge 2: Temperature and Pressure Limitations

Operating conditions involving elevated temperatures and pressures pose another critical challenge, dictating which material is suitable for the task.

Navigating Cast Iron’s Thermal Boundaries

Cast iron generally has more restricted temperature and pressure ranges compared to carbon steel. For instance, ductile iron valves are typically recommended for temperatures below 150°C and pressures not exceeding 1.6 Mpa. Beyond these limits, cast iron components, particularly valve bodies, can experience micro-deformations that compromise their integrity and operational safety. The presence of graphite, while beneficial for some properties, can also contribute to reduced thermal stability at higher temperatures. This makes cast iron ideal for applications like ordinary water and gas pipelines at ambient temperatures and pressures.

When designing for environments with fluctuating temperatures or moderate to high pressures, the inherent limitations of cast iron become apparent. This challenge necessitates careful consideration of the specific thermal and pressure demands of an application to avoid premature material failure.

Acero carbono‘s Performance Under Extremes

Carbon steel, particularly alloy steel, offers superior performance in high-temperature and high-pressure environments. For example, carbon steel valves can withstand temperatures up to 350°C and pressures ranging from 1.6 Mpa to 6.4 Mpa, making them suitable for steam, gas, and water systems under more demanding conditions. The inherent metallurgical structure of carbon steel, with its lower carbon content and the ability to form stable solid solutions and carbides (like cementite, Fe3C), allows it to maintain mechanical properties at elevated temperatures.

Specialized alloy steels, such as pearlitic heat-resistant steels, are designed to perform exceptionally well at even higher temperatures, up to 650°C, making them indispensable in critical energy infrastructure like boilers and steam pipelines. This robustness under extreme conditions makes carbon steel and its alloys the preferred choice for high-performance applications in industries like petrochemicals, where pressure vessels, reactors, and heat exchangers operate under severe stress.

When to Use Cast Iron vs Carbon Steel: A Comprehensive Guide

The decision to use cast iron vs carbon steel hinges on a thorough analysis of the specific application’s requirements, including mechanical properties, operating environment, and processing capabilities. This decision-making process is crucial for optimizing product performance and ensuring cost-effectiveness.

Here’s a comparative breakdown to aid in the selection process:

| Feature/Property | Cast Iron (Typical Properties) | Carbon Steel (Typical Properties) |

| Contenido de carbono | >2.0% (e.g., 2%–4%) | <2.0% (e.g., 0.05%–2.0%) |

| Microstructure | Carbon primarily as graphite (flakes, spheroids, clumps) | Carbon as carbides (cementite), dissolved in ferrite/austenite |

| Resistencia a la tracción | Generalmente más bajo | Generally higher |

| Compressive Strength | Alto | Bien |

| Ductility/Toughness | Low (brittle), especially grey cast iron | High (ductile), good impact resistance |

| Vibration Damping | Excellent (due to graphite) | Moderado |

| Resistencia al desgaste | Good (due to graphite/carbides) | Good, especially with higher carbon/alloying |

| Castability | Excellent (good fluidity for complex shapes) | Good, but often requires more precise control for complex shapes |

| Maquinabilidad | Good (especially grey cast iron due to graphite) | Good, but varies with hardness and carbon content |

| Soldadura | Difficult, especially grey cast iron | Generally good, varies with carbon content |

| Max. Temp (Valves) | <150°C (Ductile Iron) | <350°C (Carbon Steel) |

| Max. Pressure (Valves) | <1.6 Mpa (Ductile Iron) | 1.6 – 6.4 Mpa (Carbon Steel) |

| Resistencia a la corrosión | Varies, ductile iron can be better than carbon steel in water | Good, significantly improved with alloying |

| Costo | Generally lower (especially ductile iron in water systems) | Generally higher |

Applications Favoring Cast Iron

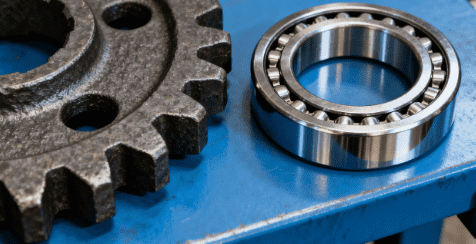

Cast iron excels in applications where its unique combination of properties is advantageous. Its excellent castability allows for the production of intricate and complex shapes, which is a significant benefit in general casting. Furthermore, its superior vibration damping capacity makes it ideal for machine tool beds, engine blocks, and hydraulic components where minimizing noise and vibration is crucial. For valve bodies in low-pressure, ambient temperature water or gas pipelines, ductile iron often provides a cost-effective and sufficiently robust solution, even offering comparable tensile and yield strength to carbon steel in these environments, sometimes with better corrosion and oxidation resistance.

Components such as safety valve bodies, centrifugal pump impellers, and various valve and pump accessories can benefit from cast iron’s properties, particularly when produced with precision casting techniques like those using silica sol processing.

Applications Demanding Acero carbono

Carbon steel and its alloy variants are indispensable for applications requiring high strength, excellent toughness, and resistance to extreme temperatures and pressures. In industries such as automotive manufacturing, carbon steel and alloy steel are crucial for key components like engine mounts, transmission housings, and brake system components, where they meet stringent performance, consistency, and quality control requirements. The ability of carbon steel to withstand high-temperature, high-pressure, and corrosive conditions makes it the material of choice for valve and pump manufacturing, particularly for high-performance valves and pump bodies.

Heavy machinery parts, such as rolling mill frames and hydraulic press bases, which endure significant static and dynamic loads, rely on the high strength and toughness of cast carbon steel. Similarly, railway vehicle components like bolsters and side frames, which must withstand substantial forces and impacts, are typically made from cast carbon steel. The superior high-temperature stability of alloy steels, such as pearlitic heat-resistant steel, makes them essential for power generation and petrochemical industries, where equipment operates under severe thermal and pressure stresses.

Manufacturing and Processing Considerations for Cast Iron vs Carbon Steel

Beyond material properties, the manufacturing and processing capabilities associated with cast iron vs carbon steel are crucial for B2B buyers. The chosen production methods, precision levels, and quality assurance protocols directly influence the final product’s quality, cost, and lead time.

Machinability and Post-Processing

Both cast iron and carbon steel can be machined, but their characteristics influence the process. Grey cast iron, with its graphite flakes, tends to have good machinability, often requiring less tool wear. Carbon steel, while machinable, can be tougher, especially with higher carbon content, which might necessitate more robust tooling and optimized machining parameters.

Modern manufacturing relies heavily on CNC machining capabilities to achieve high dimensional accuracy and ensure assembly compatibility for precision castings. After the initial casting, parts often require subsequent finishing operations such as drilling, turning, and tapping. Suppliers that offer integrated services, including comprehensive CNC machining, can provide one-stop solutions from design to finished product, solving production problems with less effort and worry.

Casting Processes and Precision

The choice of casting process is pivotal in achieving the desired precision and structural integrity for both cast iron and carbon steel components. Investment casting (also known as precision casting or lost-wax casting) and sand casting are common methods. Investment casting, particularly when utilizing the silica sol process, is highly effective for producing complex structural parts with high precision, which is critical for industries like valve and pump manufacturing.

Advanced technologies like industrial 3D printing and rapid casting are also transforming the manufacturing field, offering innovative momentum for efficient production. These technologies support flexible customization, meeting the needs of single-piece, small-batch, and large-scale production, and can enable rapid prototyping within 7 to 30 days depending on the method. Suppliers actively engaged in 3D printing solutions and mastering advanced 3D printing technology demonstrate a commitment to technological leadership and innovative manufacturing.

Quality Control and Certifications

Quality is non-negotiable in precision metal parts manufacturing. Regardless of whether cast iron or carbon steel is chosen, a comprehensive quality control system is essential. This system should cover every step, from raw material procurement to machining processes and final inspection. For critical components, strict adherence to drawing standards and customer specifications is paramount.

Certifications such as ISO 9001:2015 and IATF 16949:2016 are critical, particularly for industries like automotive manufacturing, where they signify stringent requirements for component performance, consistency, and quality control. A reliable manufacturing partner will implement strict inspection procedures to ensure the reliability and optimal performance of every project and should welcome third-party inspections or factory audits. Furthermore, an experienced supplier in the precision casting and metal casting industry, with over 18 to 20 years of focus on the manufacturing field, can offer invaluable expertise and ensure adherence to the highest quality standards.

Conclusión

The dichotomy of hierro fundido vs acero al carbono presents manufacturers with a classic engineering challenge. While cast iron offers excellent castability, high compressive strength, and vibration damping properties, it suffers from brittleness and limited temperature/pressure resistance. Conversely, carbon steel provides superior strength, ductility, toughness, and robust performance under extreme conditions, though often at a higher cost or requiring more complex processing for intricate designs.

Making a smart selection requires a holistic understanding of the application’s demands, the material’s inherent characteristics, and the capabilities of the manufacturing partner. Factors such as specific mechanical property requirements (strength, toughness, wear resistance), operating environment (temperature, pressure, corrosive media), and manufacturing considerations (casting precision, machinability, cost, lead time, and quality control) must all be weighed carefully.

By leveraging expert guidance, advanced casting technologies like investment casting and 3D printing, and rigorous quality management systems, manufacturers can optimize their material choices to meet global application requirements. Ultimately, selecting the ideal material for each unique project is about achieving the perfect balance of performance, reliability, and cost-efficiency.

PREGUNTAS FRECUENTES

Q1: What is the primary difference between cast iron and carbon steel?

A1: The primary difference is their carbon content. Cast iron typically has over 2% carbon, while carbon steel has less than 2% carbon. This carbon content significantly influences their microstructures and mechanical properties.

Q2: Which material is better for high-impact applications?

A2: Carbon steel is generally better for high-impact applications due to its higher ductility and toughness, which allow it to absorb energy and deform before fracturing. Cast iron, being more brittle, is less suitable for such dynamic loads.

Q3: Can cast iron be used in high-temperature or high-pressure environments?

A3: Generally, cast iron has limitations in high-temperature and high-pressure environments. For instance, ductile iron valves are typically recommended for temperatures below 150°C and pressures under 1.6 Mpa. Carbon steel and its alloys are better suited for more extreme conditions.

Q4: Which material is easier to cast into complex shapes?

A4: Cast iron, particularly grey cast iron, generally exhibits excellent castability due to its good fluidity, making it easier to cast into complex shapes. However, advanced precision casting techniques can also achieve high precision for complex carbon steel parts.

Q5: How can I ensure the quality of cast iron or carbon steel components?

A5: Ensuring quality involves partnering with manufacturers who have comprehensive quality control systems, from raw material procurement to final inspection. Look for certifications like ISO 9001:2015 and IATF 16949:2016, especially for critical industries like automotive. Third-party inspections and factory audits are also valuable.

Manténgase conectado con nosotros

¡Gracias por leer! Esperamos que este blog te haya brindado información valiosa e inspiración sobre techos con paneles acústicos. Si disfrutaste del contenido y quieres estar al día de las últimas tendencias, consejos y novedades, nos encantaría conectar contigo en redes sociales.

📘 Síguenos en Facebook: Shanghai Leierwo Industria Comercio Co., Ltd.

Únase a nuestra creciente comunidad donde compartimos consejos de expertos, aspectos destacados de los productos y debates interactivos con profesionales y entusiastas del diseño de todo el mundo.

Sigamos conversando, ¡nos vemos allí!

Categorías de productos

- Piezas de válvulas

- Piezas de la bomba de agua

- Piezas de la caja de cojinetes

- Piezas de fundición a presión

- Productos para bombas de acero inoxidable

- Productos para bombas de hierro fundido

- Piezas de válvulas para automóviles

- Recambios para automóviles

- Piezas de válvulas para uso civil

- Piezas de bomba de vacío KF