Acero al carbono 1045: una solución confiable de fundición de precisión

Tabla de contenido

Introducción

In the world of precision casting, the selection of materials is crucial to the performance, longevity, and reliability of your components. One material that stands out for its durability, versatility, and strength is 1045 carbon steel. This medium-carbon steel is widely used in industries like automotive, aerospace, machinery, and manufacturing, making it an essential choice for many precision casting projects.

With Leierwo’s 18 years of expertise in the precision casting and metalworking industries, we offer customized, high-quality 1045 carbon steel parts designed to meet your specifications. Our factory operates under ISO 9001:2015 y IATF 16949:2016 certifications, ensuring strict quality control at every step of the production process. Whether it’s for gears, shafts, or other components, 1045 carbon steel is often the ideal solution for parts that require moderate strength, toughness, and wear resistance.

In this blog post, we will explore the key features, benefits, and applications of 1045 steel in the context of precision casting. We will also highlight how Leierwo can assist in producing high-quality 1045 carbon steel components for a wide range of industries.

Qué es Acero al carbono 1045?

Understanding 1045 Carbon Steel Composition

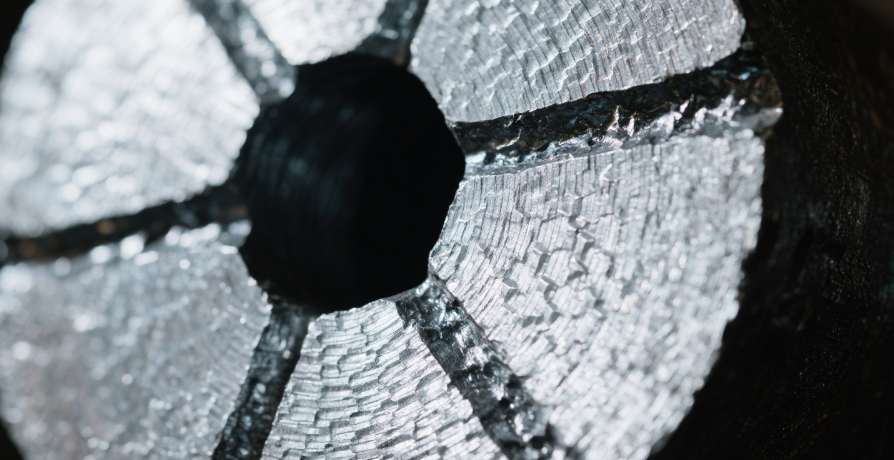

1045 carbon steel is often referred to as “medium carbon steel” because of its carbon content, which typically falls in the range of 0.43% to 0.50%. This makes it a stronger alternative to lower-carbon steels, which are easier to form and weld but don’t provide the same strength. The higher carbon content in 1045 improves its hardness, tensile strength, and wear resistance, making it an excellent choice for components that need to withstand high levels of stress and mechanical forces.

Here is a breakdown of the typical composition of 1045 carbon steel:

- Carbono (C): 0.43% – 0.50%

- Manganeso (Mn): 0.60% – 0.90%

- Fósforo (P): 0.04% max

- Azufre (S): 0.05% max

- Hierro (Fe): Balance

This composition provides a balanced combination of strength, toughness, and resistance to wear. Additionally, 1045 carbon steel is relatively easy to machine compared to higher carbon steels, which makes it suitable for various manufacturing processes, including fundición de precisión y Mecanizado CNC.

Why Choose 1045 Carbon Steel for Your Components?

- Durability and Strength: With its balanced carbon content, 1045 offers excellent tensile strength, ranging from 570 to 700 MPa, which ensures the durability of the components.

- Maquinabilidad: Unlike higher-carbon steels, 1045 carbon steel provides a good level of machinability, which is essential in precision casting and CNC machining processes.

- Hardening Capabilities: It responds well to heat treatment processes, such as induction hardening, which increases surface hardness while maintaining core toughness.

- Costo-efectividad: While offering great mechanical properties, 1045 is more affordable compared to high-alloy steels, making it a cost-effective option for medium-strength applications.

En Leierwo, we specialize in fundición de precisión y Mecanizado CNC for custom parts made from 1045 carbon steel, tailored to meet the unique needs of our clients. Our experience and expertise allow us to provide high-quality solutions with an emphasis on strength, durability, and performance.

Key Applications of 1045 Carbon Steel

Common Uses in Manufacturing and Industry

1045 carbon steel is a versatile material used in a wide range of applications that require moderate strength, toughness, and wear resistance. Some of the most common applications include:

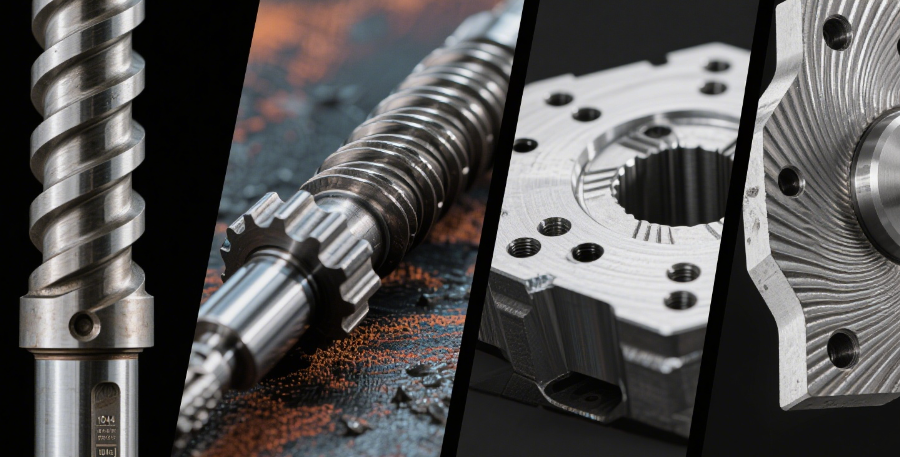

- Shafts: Used in machinery and heavy equipment, shafts made from 1045 are strong enough to handle torsional stresses while maintaining ductility.

- Gears and Crankshafts: The ability to undergo heat treatment allows 1045 steel to be used in the production of gears and crankshafts for internal combustion engines.

- Hydraulic and Pneumatic Cylinder Rods: In hydraulic and pneumatic systems, 1045 carbon steel’s wear resistance and strength are essential in ensuring the longevity of cylinder rods.

- Componentes automotrices: Parts such as axles, rods, and bearing housings, which are subjected to high stress, are often made from 1045 carbon steel due to its excellent strength and machinability.

- Industrial Tools: 1045 carbon steel is used for producing tools like spindles, valve bodies, and other machinery components where strength and durability are necessary.

En Leierwo, we offer a wide range of customized solutions for parts made from 1045 carbon steel. Our engineers work closely with you to design and produce the best components that meet your specific needs, while our precision casting and machining services ensure the highest quality at every stage of production.

The Benefits of 1045 Carbon Steel in Precision Casting

Superior Toughness and Hardness

One of the primary benefits of 1045 carbon steel is its toughness. The material’s hardness can reach HB 170 to 250, making it suitable for applications that require resistance to wear, impact, and stress. When subjected to heat treatment, such as induction hardening, it can achieve a significant increase in surface hardness, which is ideal for parts that need to withstand abrasive environments.

Excellent Weldability and Formability

1045 carbon steel has a moderate carbon content, which makes it more suitable for welding than higher-carbon steels. This property is essential for the casting process, especially when parts need to be assembled after casting. Its formability also ensures that it can be cast into intricate shapes without compromising structural integrity.

High Response to Heat Treatment

Due to its medium carbon content, the carbon steel responds exceptionally well to heat treatments such as normalizing, annealing, y hardening. These processes increase the hardness and strength of the material, making it well-suited for parts like gears, shafts, and other components that must endure high stress and wear.

How Leierwo Leverages 1045 Carbon Steel for Precision Casting

Our Expertise in 1045 Carbon Steel Casting

En Leierwo, we have over 18 years of experience in producing high-quality components using 1045 carbon steel. Our expertise in fundición de precisión, fundición en arena, y Mecanizado CNC allows us to create precise and reliable parts that meet the highest industry standards.

Here are some ways Leierwo stands out in using 1045 steel for precision casting:

- Customized Solutions: We work directly with clients to understand their specific needs and provide customized casting solutions that meet all requirements.

- Advanced Technology: Our factory uses state-of-the-art casting and CNC machining equipment, ensuring that every component is produced with the highest degree of precision.

- Quality Control: We perform rigorous inspection and testing at every stage of the production process, from initial casting to final machining, ensuring all parts meet our strict quality standards.

CNC Machining Services for 1045 Carbon Steel

In addition to casting, Leierwo offers comprehensive Servicios de mecanizado CNC to finish the casting process. After casting, parts made from 1045 carbon steel can undergo precision machining to achieve the required dimensions and surface finishes. Services such as drilling, tapping, turning, y milling can be applied to ensure that even the most intricate components are produced with exact specifications.

Here’s a look at our services:

| Servicio | Descripción | Benefit |

|---|---|---|

| Fundición de precisión | Custom molds based on part design for complex geometries. | High dimensional accuracy. |

| Mecanizado CNC | Advanced post-casting processes such as milling and turning. | Precise features and surface finish. |

| Seguro de calidad | In-depth inspection, including mechanical tests. | Ensuring component reliability. |

| Global Delivery | Fast lead times with batch shipping for urgent orders. | On-time delivery for critical projects. |

Conclusión

1045 carbon steel offers an excellent combination of strength, machinability, and wear resistance, making it an ideal material for a wide range of applications. From automotive components to hydraulic systems and gears, 1045 carbon steel is versatile and cost-effective, providing a durable solution for precision casting projects.

En Leierwo, we specialize in precision casting and CNC machining services for 1045 steel components. With our extensive experience and cutting-edge technology, we ensure that every part we produce meets your exact requirements. Whether you need a customized solution for a new project or have specific design specifications, we are here to help.

For more information or to request a quote, please contact us at Leierwo. Our team of experts will guide you through the process and provide the best solution for your precision casting needs.

PREGUNTAS FRECUENTES

What industries use 1045 carbon steel?

1045 carbon steel is widely used in industries such as automotive, aerospace, machinery, construction, and manufacturing. It is ideal for applications where moderate strength, toughness, and wear resistance are required.

Can 1045 carbon steel be welded?

Sí, 1045 carbon steel has good weldability, which makes it suitable for welding in a variety of applications. However, preheating and post-weld heat treatment are recommended for thicker sections to prevent cracking.

How does Leierwo ensure the quality of 1045 carbon steel parts?

En Leierwo, we implement a rigorous quality control process that includes mechanical testing, dimensional inspection, and visual checks. All parts undergo testing to ensure they meet industry standards before being shipped.

What is the hardness of 1045 carbon steel?

1045 carbon steel typically has a hardness of around HB 170 to 250 in its as-cast state. After heat treatment, it can achieve higher hardness levels depending on the specific process used.

For more detailed information or to get a quote for your project, don’t hesitate to contact us at Leierwo. We are here to help you find the perfect casting solution for your needs.

Manténgase conectado con nosotros

¡Gracias por leer! Esperamos que este blog te haya brindado información valiosa e inspiración sobre techos con paneles acústicos. Si disfrutaste del contenido y quieres estar al día de las últimas tendencias, consejos y novedades, nos encantaría conectar contigo en redes sociales.

📘 Síguenos en Facebook: Shanghai Leierwo Industria Comercio Co., Ltd.

Únase a nuestra creciente comunidad donde compartimos consejos de expertos, aspectos destacados de los productos y debates interactivos con profesionales y entusiastas del diseño de todo el mundo.

Sigamos conversando, ¡nos vemos allí!

Categorías de productos

- Piezas de válvulas

- Piezas de la bomba de agua

- Piezas de la caja de cojinetes

- Piezas de fundición a presión

- Productos para bombas de acero inoxidable

- Productos para bombas de hierro fundido

- Piezas de válvulas para automóviles

- Recambios para automóviles

- Piezas de válvulas para uso civil

- Piezas de bomba de vacío KF