¿Qué es el acero al carbono 1018? Una guía completa

Tabla de contenido

Introducción

1018 carbon steel is a widely used low-carbon steel alloy, recognized for its excellent combination of strength, workability, and cost-effectiveness. It is one of the most commonly employed steels in various industrial sectors. Whether you’re in automotive, manufacturing, or machining, 1018 carbon steel is frequently chosen for applications where both performance and affordability are essential.

This steel alloy, with its precise composition and properties, offers versatility across numerous industries. Its ability to handle moderate strength applications without compromising on machinability makes it an invaluable material in both production and fabrication environments. This guide will help you understand the key characteristics, applications, and advantages of 1018 carbon steel, as well as its significance in various manufacturing and casting processes.

What is 1018 Carbon Steel?

1018 carbon steel is a low-carbon steel, with a carbon content of approximately 0.18%. This makes it relatively softer than other carbon steels, such as 1045 steel, which is considered a medium-carbon steel. Despite its lower carbon content, 1018 still offers an excellent balance of strength, machinability, and versatility. It’s important to note that 1018 carbon steel is a member of the SAE (Society of Automotive Engineers) steel grade classification system, which is widely used in engineering and manufacturing industries worldwide.

The alloying elements in 1018 steel include iron, a small amount of carbon (0.18%), manganese (up to 0.9%), and trace amounts of sulfur and phosphorus. These elements play a role in enhancing its mechanical properties, such as tensile strength, ductility, and formability. The low carbon content of 1018 steel allows it to be easily welded and machined, making it suitable for a wide range of applications.

Key Properties of 1018 Carbon Steel

Strength and Hardness

1018 carbon steel is known for its moderate strength, which makes it a versatile material for a variety of industrial applications. Its tensile strength typically ranges from 440 to 600 MPa (64 to 87 ksi), depending on the specific heat treatment process used. While it is not as strong as higher-carbon steels like 1045, 1018 still provides sufficient strength for most medium-duty applications, making it ideal for parts such as shafts, rods, and machine components.

Hardness in 1018 steel is typically around 120-160 HB (Brinell Hardness), though this can be increased through heat treatment processes like quenching and tempering. This characteristic makes it useful for parts requiring durability but not excessive hardness or resistance to wear.

Workability and Machinability

One of the standout features of 1018 steel is its excellent machinability. The steel can be easily processed using common machining techniques, such as turning, drilling, milling, and grinding. This is attributed to its low carbon content, which makes it easy to cut and shape without causing undue wear on tools. The material’s machinability is one reason it is often used in parts that require high precision and consistency.

In addition to machining, 1018 steel can also be bent, formed, and fabricated without compromising its structural integrity. This flexibility in manufacturing makes it a popular choice for components that need to be customized to fit specific requirements.

Soldabilidad

Due to its low carbon content, 1018 steel has excellent weldability compared to higher-carbon steels. It is less prone to cracking during the welding process, which is a significant advantage for manufacturers. Whether using MIG, TIG, or stick welding methods, 1018 carbon steel can be easily joined without requiring special procedures or post-weld heat treatments. This makes it an excellent option for welded structural components and machinery parts.

Resistencia a la corrosión

1018 carbon steel, like most carbon steels, is not naturally corrosion-resistant. It is susceptible to rust and corrosion when exposed to moisture and oxygen. However, it can be treated to improve its resistance to environmental factors. Common treatments include galvanizing (coating the steel with a layer of zinc) or painting the surface to protect it from corrosion. For applications that involve exposure to harsh environments, 1018 carbon steel can also be alloyed with other elements to enhance its corrosion resistance.

Applications of 1018 Carbon Steel

Due to its excellent combination of strength, machinability, and affordability, 1018 carbon steel finds applications in numerous industries. Below are some common uses:

Industria automotriz

In the automotive sector, 1018 steel is often used for making components that require moderate strength and excellent formability. It is commonly found in parts like gears, axles, spindles, and shafts. The steel’s ability to resist deformation and its good machinability make it ideal for parts that require precision and consistent performance.

Machine Components

1018 carbon steel is used to produce machine components such as pins, rods, and bushings. The steel’s combination of workability and strength makes it suitable for these high-precision parts. Components such as valve bodies, linkages, and gears are also often made from 1018 due to its good balance of strength and machinability.

Structural Applications

Thanks to its good weldability and moderate strength, 1018 carbon steel is used in various structural applications. It is commonly used in building frames, construction machinery, and structural beams. In these applications, 1018 steel provides the necessary strength while being relatively easy to work with during fabrication.

Shafts, Bearings, and Gears

Shafts, bearings, and gears are essential components in mechanical systems, and 1018 steel is widely used to produce them. The material’s ability to handle moderate stress and wear makes it a good choice for these applications. Additionally, 1018 can be easily machined to meet precise tolerances, ensuring smooth and reliable operation.

1018 Carbon Steel in the Casting Industry

En el casting, 1018 carbon steel stands out for its versatility and ease of processing. It is often used in various casting methods, such as sand casting and die casting, due to its good flowability and relatively low melting point. The alloy’s properties, such as its moderate strength and machinability, make it ideal for casting intricate shapes while maintaining material integrity.

Some of the casting applications for 1018 steel include:

- Fundición en arena: 1018 carbon steel can be poured into sand molds to produce cast parts. Its ability to flow into molds without excessive shrinkage or cracking makes it suitable for complex shapes.

- Fundición a presión: In die casting, 1018 steel can be used to produce small, high-precision parts such as gears, bearings, and bushings. The steel’s low carbon content reduces the likelihood of hardening during the casting process.

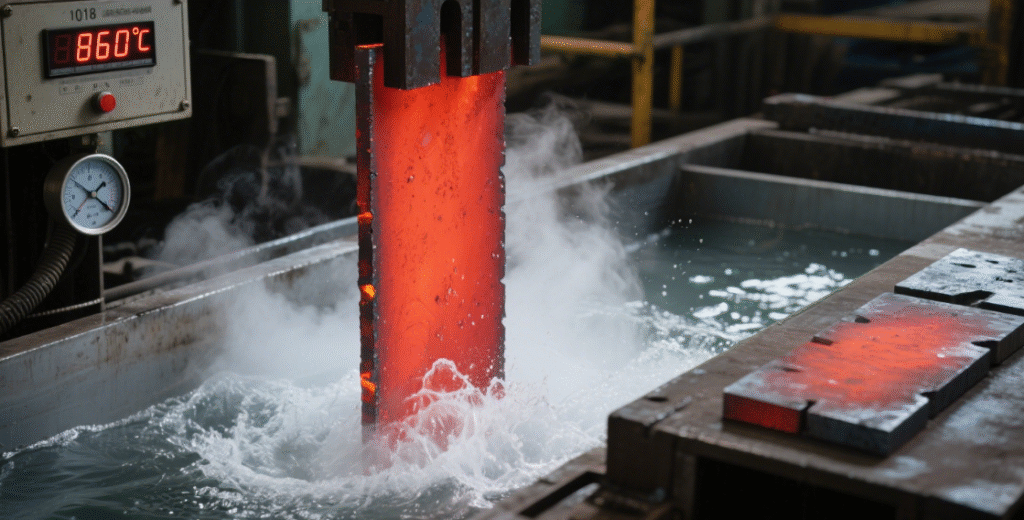

- Forja: 1018 is also used in forging processes where it is shaped under high pressure to produce parts like shafts and gears.

The casting industry benefits from 1018 carbon steel’s ability to produce durable, high-quality parts while maintaining cost-effectiveness and ease of processing.

Table: Key Properties and Applications of 1018 Carbon Steel

| Propiedad | Details |

|---|---|

| Contenido de carbono | 0.18% |

| Resistencia a la tracción | 440 – 600 MPa (64 – 87 ksi) |

| Hardness | 120 – 160 HB |

| Maquinabilidad | Excellent for machining and forming |

| Soldabilidad | Very good, low risk of cracking |

| Aplicaciones | Automotive parts, gears, structural beams, rods, pins, shafts |

| Resistencia a la corrosión | Moderate, requires coatings or treatments |

| Casting Suitability | Suitable for sand and die casting processes |

Ventajas de Acero al carbono 1018

- Rentable: Compared to higher-strength steels, 1018 is inexpensive, which makes it a cost-effective choice for manufacturers without compromising on performance.

- Versatilidad: 1018 carbon steel’s ability to be easily welded, fabricated, and machined makes it one of the most versatile steel alloys in manufacturing.

- Good Toughness: It exhibits good toughness at low to moderate temperatures, making it suitable for applications in environments with varying conditions.

- Durabilidad: While not as durable as some high-carbon steels, 1018 offers excellent wear resistance for medium-stress applications.

- Ease of Processing: The material is easily processed, allowing for quick and cost-effective production of custom components and precision parts.

Conclusión

1018 carbon steel is a versatile, cost-effective material widely used in various industries. Its combination of strength, workability, and weldability makes it an ideal choice for a range of applications, from automotive parts to machine components. In the casting industry, it stands out for its ability to be molded into complex shapes while maintaining durability. Whether you’re working in manufacturing, fabrication, or casting, 1018 carbon steel provides an excellent balance of properties for many industrial uses.

PREGUNTAS FRECUENTES

What is the difference between 1018 and 1045 steel?

The key difference between 1018 and 1045 steel is their carbon content. 1018 steel contains 0.18% carbon, while 1045 steel has 0.45%. As a result, 1045 is stronger and harder, making it suitable for applications requiring higher strength. However, 1018 is more malleable and easier to weld.

Can 1018 steel be heat treated?

Yes, 1018 steel can be heat treated to increase its hardness and tensile strength. It is typically subjected to a process known as carburizing, which involves heating the steel in a carbon-rich environment to improve surface hardness.

What industries use 1018 carbon steel?

Industries that commonly use 1018 steel include automotive, construction, manufacturing, and machining. It is widely used in applications that require moderate strength, workability, and durability.

What are the welding considerations for 1018 steel?

1018 steel is easy to weld, but care should be taken to avoid overheating during the welding process, as excessive heat can lead to

Manténgase conectado con nosotros

¡Gracias por leer! Esperamos que este blog te haya brindado información valiosa e inspiración sobre techos con paneles acústicos. Si disfrutaste del contenido y quieres estar al día de las últimas tendencias, consejos y novedades, nos encantaría conectar contigo en redes sociales.

📘 Síguenos en Facebook: Shanghai Leierwo Industria Comercio Co., Ltd.

Únase a nuestra creciente comunidad donde compartimos consejos de expertos, aspectos destacados de los productos y debates interactivos con profesionales y entusiastas del diseño de todo el mundo.

Sigamos conversando, ¡nos vemos allí!

Categorías de productos

- Piezas de válvulas

- Piezas de la bomba de agua

- Piezas de la caja de cojinetes

- Piezas de fundición a presión

- Productos para bombas de acero inoxidable

- Productos para bombas de hierro fundido

- Piezas de válvulas para automóviles

- Recambios para automóviles

- Piezas de válvulas para uso civil

- Piezas de bomba de vacío KF