8 comprobaciones clave para el procesamiento de piezas mecánicas

Tabla de contenido

Introducción

In the global manufacturing and engineering industry, finding a trustworthy partner for mechanical parts processing is critical to ensuring the quality, functionality, and longevity of your final product. Overseas buyers, particularly from North America, Europe, and the Middle East, often face several risks when outsourcing processing services to foreign suppliers, including quality inconsistency, lack of communication, delivery delays, and hidden costs.

This blog aims to provide a detailed guide for international buyers on what to examine before committing to a mechanical parts processing partner. With over 18 years of experience, Shanghai Leierwo Industry & Trade Co., Ltd. offers a case study in what reliable service looks like, from precision casting to CNC machining.

Factor 1: Evaluate Technical Capabilities and Production Processes

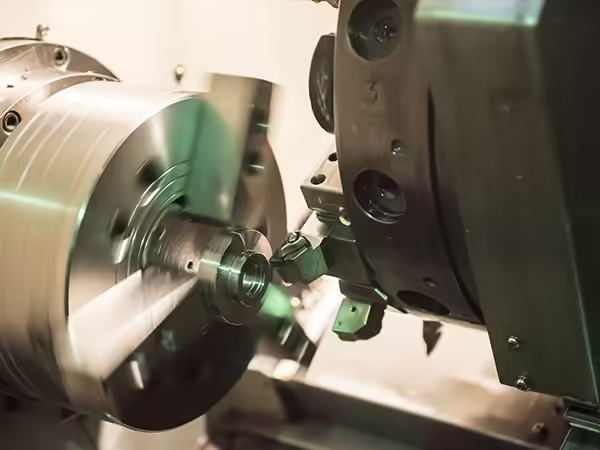

One of the foremost considerations for buyers is whether the supplier has the right capabilities and technologies for mechanical parts processing. This factor alone can determine whether your project will be successful from a design and functionality standpoint.

Investment in Technology

- Does the company use investment casting, sand casting, or composite methods?

- Are their CNC machines up-to-date with the latest tolerances and cutting-edge precision?

Suppliers involved in mechanical parts processing must stay technologically competitive. Advanced CNC machining centers, digital twin simulations, and multi-axis processing capabilities all contribute to reducing lead times and improving part accuracy.

Scope of Material Expertise

A high-quality provider should offer a variety of material processing, such as:

- Fundición de acero al carbono

- Alloy Steel Casting

- Stainless Steel Casting

These materials are commonly used in mechanical parts processing across multiple industries, including automotive, aerospace, and construction. Leierwo is a recognized leader in China in both casting and machining, offering all of the above with precision, enabling clients to tailor parts based on strength, resistance, and cost-effectiveness.ng all of the above with precision.

Factor 2: Certification and Quality Assurance Standards

Certifications are non-negotiable indicators of quality control in mechanical parts processing. They validate whether a company has standardized operating procedures and a commitment to quality.

Key Certifications to Look For

- ISO 9001:2015 – Quality Management

- IATF 16949:2016 – Automotive Industry Standards

A supplier like Leierwo, which holds both, provides confidence in both consistency and reliability. These certifications ensure a disciplined approach to mechanical parts processing, particularly when parts are to be used in mission-critical environments.

Quality Control Procedures

- Are there incoming and outgoing quality checks?

- Do they provide reports and real-time inspection updates?

Leierwo sends detailed test reports before delivery, ensuring transparency. Their inspection team adheres to strict QC protocols including visual inspection, dimensional verification, material composition testing, and functional trials when required.

Factor 3: Communication and Project Management

For international buyers, a communication breakdown can lead to serious delays or errors. Clear and professional communication is essential to effective mechanical parts processing.

Dedicated Point of Contact

- Is there a project manager who speaks fluent English or your preferred language?

- Are they available in your time zone or within a reasonable response time?

Having a consistent point of contact streamlines feedback loops, reducing misinterpretation or production errors.

Digital Tracking Systems

- Does the company use ERP or PLM systems for production tracking?

- Are there weekly updates and milestones shared?

Leierwo assigns a professional engineer to every project and uses ERP systems to manage timelines and updates. This ensures clients have complete visibility into their mechanical parts processing pipeline from day one.

Factor 4: Sample Testing and Prototyping Policies

Before committing to large-scale production, verify if your supplier offers free samples or prototyping.

Sample Policy Questions

- Is the first sample free?

- How soon can they produce and deliver the prototype?

Leierwo offers one free sample and completes prototypes within 3–5 weeks depending on complexity.

Factor 5: Experience with Global Clients and Export Services

Experience with international clients is essential for understanding regulatory, logistical, and cultural nuances.

Proven Track Record

- Does the supplier work with clients in your region?

- Can they handle compliance and shipping regulations?

Leierwo’s Global Reach

Leierwo works with clients in the U.S., Canada, Germany, France, Saudi Arabia, and more—and is well-versed in global delivery and compliance.

Table: Quick Comparison of Key Mechanical Parts Processing Considerations

| Factor | What to Check | Leierwo’s Offering |

|---|---|---|

| Technical Capabilities | Casting & CNC scope | Investment, Fundición en arena, Mecanizado CNC |

| Conocimientos sobre materiales | Steel grades & alloys | Carbon, Aleación, Acero inoxidable |

| Certifications | ISO, IATF | ISO 9001:2015, IATF 16949:2016 |

| Comunicación | Language, Tools | Fluent engineers, ERP-based updates |

| Samples | Lead time, Cost | Free sample, 3-5 weeks |

| Global Experience | Export readiness | 18 years, global shipping |

| Quality Control | Inspections, Reports | Full documentation & testing |

| Project Flexibility | Personalización | Custom based on CAD & 3D files |

Factor 6: Flexibility and Customization Options

When it comes to procesamiento de piezas mecánicas, one size does not fit all. Especially in industries like automotive, marine, and valve manufacturing, customization is not just a bonus—it’s a requirement.

Custom Design Support

A supplier’s ability to tailor components to your precise needs often defines the success of a project. It’s crucial to assess whether:

- The supplier helps optimize your design for casting, machining, or finishing processes.

- They offer constructive suggestions to improve part geometry, reduce material waste, and increase overall efficiency.

Leierwo’s engineering team actively collaborates with clients during the design stage. Through procesamiento de piezas mecánicas expertise, they suggest design modifications that enhance manufacturability without compromising performance. This added value can reduce costs and lead times while improving final product quality.

Factor 7: Delivery Timelines and Urgency Handling

Delays in mechanical parts processing can cause ripple effects throughout your entire supply chain. Evaluating a supplier’s delivery commitment is essential for time-sensitive industries.

Lead Times

Reliable partners will offer:

- Standardized production timelines and rapid prototyping services.

- Options for phased or batch delivery to accommodate tight schedules or urgent demands.

Leierwo guarantees strict adherence to delivery timelines. Their system supports urgent batch shipments, ensuring that critical mechanical parts processing orders arrive on time and in full—reducing downtime and operational risk.

Factor 8: Transparency in Quotation and Cost Breakdown

Trust begins with clear communication—especially when it comes to pricing. In mechanical parts Trust is the foundation of any successful business relationship, and in the realm of procesamiento de piezas mecánicas, it starts with clear, upfront communication about pricing. Many buyers face challenges when suppliers provide vague or incomplete quotes, which can lead to misunderstandings, unexpected expenses, and even jeopardize long-term partnerships. Without transparency in cost structure, disputes become more likely, budgets may spiral out of control, and project timelines can be disrupted.

Clarity in Pricing

When evaluating quotes from potential mechanical parts processing suppliers, international buyers should carefully scrutinize:

- Whether the quote is broken down into specific cost components, such as tooling setup, raw material procurement, machining or casting labor, finishing, and shipping expenses.

- If the pricing accounts for potential variations like changes in sample production, material substitutions, or design modifications.

- Whether payment terms, including deposits, milestones, and final payments, are clearly outlined to avoid surprises later.

Transparent pricing is especially critical for complex projects involving custom designs or multiple iterations, where costs can quickly escalate if not managed properly.

Leierwo stands out in the mechanical parts processing industry for its commitment to financial transparency. Their quotations are meticulously itemized, reflecting actual production costs without hidden fees or ambiguous charges. This approach enables buyers to understand exactly what they are paying for, facilitating better budgeting and financial planning.

Moreover, Leierwo maintains open dialogue throughout the production cycle, promptly informing clients of any cost-impacting changes, such as fluctuations in material prices or unexpected technical challenges. This proactive communication minimizes risks and fosters trust, helping international buyers confidently manage their mechanical parts processing projects from start to finish.

In summary, transparent quotations not only simplify financial decision-making but also build the strong, reliable partnerships necessary for long-term success in mechanical parts processing.

Conclusión

Choosing the right partner for mechanical parts processing isn’t just about price—it’s about trust, expertise, and capability. From casting quality to on-time delivery, every detail matters. Shanghai Leierwo Industry & Trade Co., Ltd. exemplifies these qualities with over 18 years of experience, full certification, and a global customer base.

If you’re seeking a reliable partner for precision casting, Mecanizado CNC, or material consultation, Leierwo is prepared to support your project from start to finish.

Submit your inquiry today and receive a free sample to kick off your project with Leierwo!

PREGUNTAS FRECUENTES

Q1: How long does mechanical parts processing take?

The standard lead time for prototypes is 3–5 weeks. Mass production timing depends on part complexity and volume.

Q2: Do I need to provide 3D drawings or can Leierwo assist?

Yes, CAD and 3D files are preferred, but Leierwo also offers assistance in optimizing or even redesigning your parts.

Q3: Is procesamiento de piezas mecánicas suitable for small batch orders?

Yes. Leierwo supports both low-volume and high-volume orders with batch delivery options.

Q4: What industries benefit from Leierwo’s services?

Automotive, agriculture, construction, marine, pipeline, and especially pump and valve accessories benefit from Leierwo’s services.

Q5: How can I trust the quality of parts before delivery?

Test reports and inspection documentation are provided before shipment, ensuring quality transparency and buyer confidence.

Manténgase conectado con nosotros

¡Gracias por leer! Esperamos que este blog te haya brindado información valiosa e inspiración sobre techos con paneles acústicos. Si disfrutaste del contenido y quieres estar al día de las últimas tendencias, consejos y novedades, nos encantaría conectar contigo en redes sociales.

📘 Síguenos en Facebook: Shanghai Leierwo Industria Comercio Co., Ltd.

Únase a nuestra creciente comunidad donde compartimos consejos de expertos, aspectos destacados de los productos y debates interactivos con profesionales y entusiastas del diseño de todo el mundo.

Sigamos conversando, ¡nos vemos allí!

Categorías de productos

- Piezas de válvulas

- Piezas de la bomba de agua

- Piezas de la caja de cojinetes

- Piezas de fundición a presión

- Productos para bombas de acero inoxidable

- Productos para bombas de hierro fundido

- Piezas de válvulas para automóviles

- Recambios para automóviles

- Piezas de válvulas para uso civil

- Piezas de bomba de vacío KF