Por qué la fundición de vidrio de agua es clave para piezas duraderas de maquinaria agrícola

Tabla de contenido

Introducción

Fundición de vidrio de aguaLa fundición de silicato de sodio, también conocida como fundición de silicato de sodio, es una técnica de fundición que ofrece importantes ventajas para la producción de piezas duraderas y de alta precisión, especialmente para maquinaria agrícola. Este método ofrece una resistencia excepcional, resistencia al desgaste y precisión dimensional, lo que lo convierte en la opción ideal para componentes que necesitan soportar entornos agrícolas rigurosos.

En este blog, exploraremos por qué la fundición de vidrio soluble es vital para garantizar la durabilidad de las piezas de maquinaria agrícola, cómo se compara con otros métodos de fundición y por qué los fabricantes la prefieren para obtener componentes duraderos y de alto rendimiento. Además, compartiremos consejos prácticos para seleccionar al proveedor adecuado para la fundición de vidrio soluble y cómo puede reducir los costos de mantenimiento.

Cómo la fundición de vidrio soluble mejora la durabilidad de las piezas de maquinaria agrícola

Fundición de vidrio de aguaEl proceso de fundición de silicato de sodio, también conocido como fundición de silicato de sodio, mejora significativamente la durabilidad de los componentes de maquinaria agrícola. Ofrece diversas ventajas que lo convierten en la opción ideal para piezas que deben soportar condiciones adversas y un uso intensivo en entornos agrícolas.

- Fuerza mejorada: Una de las principales ventajas de la fundición de vidrio soluble es la superior resistencia a la tracción que confiere a las piezas de maquinaria agrícola. El proceso de fundición produce componentes capaces de soportar cargas mecánicas elevadas, algo esencial en maquinaria como tractores, cosechadoras y excavadoras. Esta resistencia garantiza que las piezas funcionen eficientemente incluso en tareas agrícolas exigentes, reduciendo la probabilidad de fallo de las piezas bajo presión.

- Mayor resistencia al desgaste: La maquinaria agrícola opera en entornos donde las piezas están sujetas a fricción constante y condiciones abrasivas. Las piezas de fundición de vidrio soluble son altamente resistentes al desgaste y la abrasión, lo que las hace ideales para componentes como engranajes, ejes y bloques de motor. Esta mayor resistencia al desgaste garantiza que estas piezas conserven su integridad durante más tiempo, incluso con un uso continuo en condiciones adversas.

- Resistencia a la corrosión: Uno de los mayores desafíos en la agricultura es la exposición a diversos elementos ambientales como la lluvia, el lodo y productos químicos como fertilizantes y pesticidas. La fundición de vidrio soluble proporciona una excelente resistencia a la corrosión, protegiendo las piezas de la maquinaria de la oxidación y la degradación. Esto es especialmente importante para piezas que están constantemente expuestas a la humedad y otros elementos corrosivos, como componentes de motores y elementos estructurales.

- Alta precisión: La fundición de vidrio soluble es conocida por su excepcional precisión dimensional, un factor crucial para garantizar que las piezas de la maquinaria agrícola encajen perfectamente. Gracias a su precisa capacidad de fundición, garantiza que las piezas encajen correctamente en la maquinaria, lo que se traduce en un funcionamiento más suave, una menor fricción y una mejor funcionalidad general. Esta precisión es especialmente importante en piezas como conjuntos de engranajes y componentes de motor, donde incluso pequeñas imprecisiones pueden provocar ineficiencias y posibles averías.

La combinación de estos beneficios (resistencia superior, resistencia al desgaste, protección contra la corrosión y precisión) hace que este método de fundición sea ideal para piezas de maquinaria agrícola que necesitan soportar las rigurosas demandas de las operaciones agrícolas.

Fundición de vidrio soluble frente a métodos de fundición tradicionales para piezas agrícolas

Al evaluar los métodos de fundición para componentes de maquinaria agrícola, la comparación de la fundición con vidrio soluble con las técnicas tradicionales revela diferencias significativas en calidad, precisión y rentabilidad. A continuación, se presenta una comparación detallada de la fundición con vidrio soluble con otros métodos de fundición comunes.

| Tipo de proceso | Precisión dimensional (ISO 8062) | Rugosidad superficial (Ra) | Nivel de costo | Escenarios típicos de aplicación |

|---|---|---|---|---|

| Fundición de vidrio de agua | CT7-CT8 | 12.5 | Medio | Piezas de excavadoras, maquinaria agrícola, piezas estructurales de camiones |

| Fundición en arena | CT8-CT10 | 25-50 | Bajo | Piezas industriales grandes |

| Fundición a presión | CT4-CT6 | 6-12 | Alto | Piezas automotrices de alta precisión |

| Fundición en molde permanente | CT6-CT8 | 12-20 | Medio | Componentes de maquinaria |

Observaciones clave:

- Precisión y acabado superficial: El método de fundición de vidrio soluble ofrece un equilibrio entre coste y precisión, proporcionando piezas con precisión dimensional (CT7-CT8) y una rugosidad superficial razonable (Ra 12,5). Esto lo hace adecuado para piezas agrícolas que requieren ajuste y funcionalidad.

- Costo-efectividad: En comparación con métodos costosos como la fundición a presión, la fundición de vidrio soluble ofrece una solución más asequible para la fabricación de componentes agrícolas, garantizando al mismo tiempo una alta calidad. Esto la convierte en la opción ideal tanto para fabricantes preocupados por los costes como por la calidad.

Cómo Fundición de vidrio de agua Reduce los costos de mantenimiento en maquinaria agrícola

La durabilidad y el rendimiento a largo plazo de las piezas producidas mediante fundición de vidrio soluble reducen los costos de mantenimiento. A continuación, se presentan varias maneras en que este proceso de fundición ayuda a reducir el costo total de propiedad de la maquinaria agrícola:

- Longevidad: Gracias a su superior resistencia y resistencia al desgaste, las piezas fundidas en vidrio soluble duran más que las fabricadas con métodos tradicionales. Componentes como bloques de motor, engranajes y piezas estructurales experimentan menos fallos, lo que se traduce en una reducción del tiempo de inactividad y de las sustituciones. Esto supone un ahorro significativo de tiempo y dinero.

- Resistencia a la corrosión: Las piezas fabricadas con esta técnica de fundición son resistentes a la corrosión y al desgaste, lo que significa que son menos propensas a fallar debido a la exposición ambiental. Por ejemplo, los componentes expuestos a la lluvia, el barro y los productos químicos en las granjas se mantienen intactos durante más tiempo. Esto reduce la necesidad de reparaciones costosas y aumenta la vida útil de la maquinaria agrícola.

- Bajo desgaste: Dado que la fundición de vidrio soluble garantiza una alta precisión y menos defectos, las piezas de la maquinaria funcionan con mayor eficiencia. Esto reduce el desgaste de otras piezas, lo que a su vez reduce las necesidades de mantenimiento. Al garantizar un funcionamiento más suave, esta técnica mejora la eficiencia general de la maquinaria, reduciendo los costos de reparación y operación.

Al utilizar este proceso de fundición, los fabricantes de maquinaria agrícola pueden producir piezas más confiables, lo que resulta en menos reparaciones, menos tiempo de inactividad y un menor costo total de propiedad del equipo.

Fundición de vidrio de agua:Mejora del rendimiento de los equipos agrícolas

El rendimiento de la maquinaria agrícola depende directamente de la resistencia y durabilidad de sus componentes. La fundición de vidrio soluble contribuye significativamente a este rendimiento, especialmente en componentes críticos:

- Componentes del motor:

- Culatas: La fundición de vidrio soluble permite la producción de culatas lo suficientemente resistentes para soportar las altas presiones y temperaturas típicas del funcionamiento de los motores de la maquinaria agrícola.

- Bloques: Los bloques de motor fundidos con este método son resistentes al agrietamiento y la deformación, lo que garantiza un rendimiento constante durante toda la vida útil de la máquina.

- Componentes del engranaje:

- Engranajes y ejes: Estas piezas están sujetas a fuertes cargas mecánicas durante su funcionamiento. Gracias a la fundición de vidrio soluble, los engranajes y ejes pueden soportar movimientos repetitivos sin fallar, lo cual es esencial para el rendimiento eficiente de la máquina.

- Componentes estructurales:

- Marcos y carcasas: Los bastidores y las carcasas son fundamentales para la resistencia y durabilidad general de la maquinaria. La fundición de vidrio soluble garantiza la resistencia de estos componentes a impactos y tensiones, proporcionando una base robusta para la maquinaria agrícola que opera en entornos difíciles.

La maquinaria de alto rendimiento depende de la integridad y fiabilidad de estas piezas. Mediante este método de fundición, los fabricantes pueden producir componentes que ofrecen resistencia, precisión y durabilidad excepcionales, lo que resulta en maquinaria más eficiente y un rendimiento más duradero.

Cómo Fundición de vidrio de agua Contribuye a la sostenibilidad en la agricultura

La sostenibilidad cobra cada vez mayor importancia en la industria manufacturera, y la industria de la maquinaria agrícola no es la excepción. La fundición de vidrio soluble ofrece varias ventajas que contribuyen a las prácticas de producción sostenibles:

- Reducción de residuos: El proceso produce menos residuos en comparación con los métodos tradicionales, como la fundición en arena, donde a menudo se desecha mucho material.

- Menor consumo de energía: Los requerimientos energéticos para la fundición de vidrio soluble son menores que los de la fundición a presión, lo que lo convierte en un proceso de fabricación más eficiente energéticamente. Esta reducción del consumo energético no solo disminuye los costos de producción, sino que también contribuye a una operación más sostenible.

- Materiales reciclables: Los materiales utilizados en la fundición de vidrio soluble, como la arena de sílice y el silicato de sodio, son altamente reciclables. Esto significa que el proceso de producción contribuye a un modelo de fabricación circular, donde los materiales pueden reutilizarse en lugar de desecharse, lo que contribuye a los objetivos de sostenibilidad.

La fundición de vidrio acuoso permite a los fabricantes reducir su huella ambiental y, al mismo tiempo, satisfacer las altas demandas de piezas de maquinaria agrícola duraderas y eficientes.

Cómo elegir el proveedor adecuado en agricultura

A la hora de seleccionar un proveedor para la fundición de vidrio de agua, es importante centrarse en varios factores clave para garantizar piezas duraderas y de alta calidad para su maquinaria agrícola:

- Experiencia en fabricación de piezas agrícolas: Elija un proveedor con experiencia demostrada en la producción de componentes agrícolas. Esta experiencia garantiza que comprenda las necesidades específicas de la industria agrícola y pueda suministrar piezas que cumplan con los estándares requeridos.

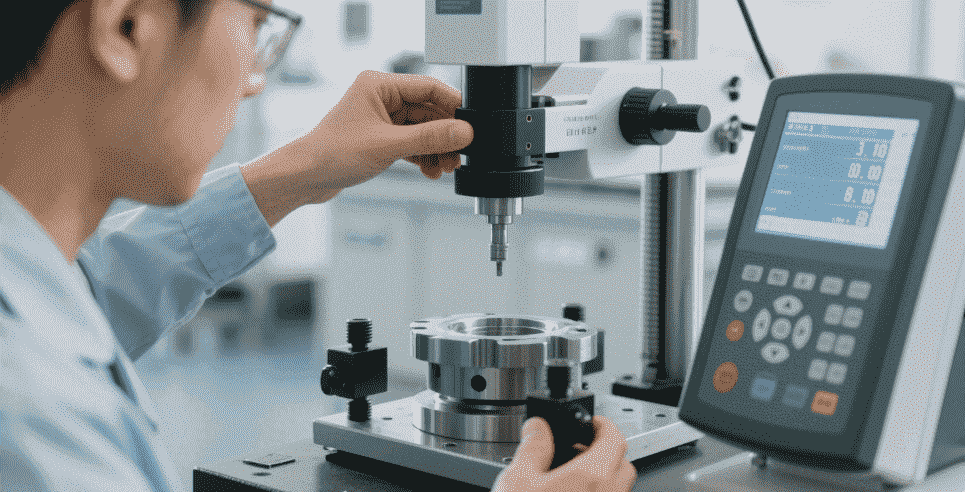

- Precisión y control de calidad: Asegúrese de que el proveedor pueda garantizar una alta precisión dimensional y un acabado superficial uniforme. El control de calidad es crucial para mantener la funcionalidad y la longevidad de las piezas de maquinaria agrícola.

- Tecnología y equipamiento: El proveedor debe utilizar tecnología y equipos de fundición modernos para garantizar que las piezas se fabriquen con la máxima calidad posible. La maquinaria de vanguardia permite una producción más precisa y eficiente.

- Costo y puntualidad: Si bien la calidad es esencial, el proveedor también debe ofrecer precios competitivos y cumplir con los plazos de entrega. Un proveedor confiable puede ayudarle a evitar retrasos en la producción y a mantener los costos bajo control.

Al seleccionar cuidadosamente un proveedor que cumpla con estos criterios, puede asegurarse de que las piezas de su maquinaria agrícola sean de la más alta calidad, lo que ayudará a reducir los costos a largo plazo y mejorar el rendimiento.

Conclusión

Fundición de vidrio de agua Es indispensable en la fabricación de piezas de maquinaria agrícola duraderas y de alta precisión. Ofrece una combinación equilibrada de rentabilidad, robustez, resistencia al desgaste y precisión, lo que la hace ideal para componentes que deben soportar las rigurosas condiciones de las operaciones agrícolas. Desde la reducción de los costes de mantenimiento hasta la mejora del rendimiento de la maquinaria, la fundición de vidrio soluble ofrece a los fabricantes una ventaja competitiva en la producción de piezas duraderas y de alto rendimiento.

A medida que la maquinaria agrícola evoluciona, la demanda de piezas duraderas, eficientes y sostenibles no hará más que aumentar. La fundición de vidrio soluble es un proceso crucial que permite a los fabricantes satisfacer estas necesidades manteniendo altos estándares de calidad.

PREGUNTAS FRECUENTES

¿Cuáles son las principales ventajas de fundición de vidrio de agua ¿Para maquinaria agrícola?

La fundición de vidrio de agua ofrece una excelente resistencia al desgaste, resistencia a la corrosión, precisión dimensional y precisión, lo que lo hace ideal para piezas de maquinaria agrícola.

¿Cómo se compara la fundición de vidrio soluble con los métodos de fundición tradicionales?

En comparación con métodos como la fundición en arena, la fundición con vidrio de agua ofrece una mejor precisión y acabado superficial y, al mismo tiempo, sigue siendo rentable, lo que la hace adecuada para piezas agrícolas de alto rendimiento.

Poder fundición de vidrio de agua ¿Se puede utilizar para todas las piezas de maquinaria agrícola?

Sí, se utiliza ampliamente para componentes críticos como bloques de motor, engranajes y piezas estructurales que requieren alta resistencia y durabilidad.

¿Cómo funciona? fundición de vidrio de agua ¿Reducir los costes de mantenimiento?

Su resistencia al desgaste, resistencia a la corrosión y alta durabilidad reducen la frecuencia de reparaciones y reemplazos de piezas, lo que genera menores costos de mantenimiento a lo largo del tiempo.

¿Qué debo tener en cuenta al elegir un proveedor para la fundición de vidrio de agua?

Busque un proveedor con experiencia en la fabricación de piezas agrícolas, control de calidad comprobado, tecnología avanzada y precios rentables.

Manténgase conectado con nosotros

¡Gracias por leer! Esperamos que este blog te haya brindado información valiosa e inspiración sobre techos con paneles acústicos. Si disfrutaste del contenido y quieres estar al día de las últimas tendencias, consejos y novedades, nos encantaría conectar contigo en redes sociales.

📘 Síguenos en Facebook: Shanghai Leierwo Industria Comercio Co., Ltd.

Únase a nuestra creciente comunidad donde compartimos consejos de expertos, aspectos destacados de los productos y debates interactivos con profesionales y entusiastas del diseño de todo el mundo.

Sigamos conversando, ¡nos vemos allí!

Categorías de productos

- Piezas de válvulas

- Piezas de la bomba de agua

- Piezas de la caja de cojinetes

- Piezas de fundición a presión

- Productos para bombas de acero inoxidable

- Productos para bombas de hierro fundido

- Piezas de válvulas para automóviles

- Recambios para automóviles

- Piezas de válvulas para uso civil

- Piezas de bomba de vacío KF