Aluminio y sus aleaciones

El aluminio y sus aleaciones se utilizan ampliamente en la fundición de precisión debido a su excepcional resistencia a altas temperaturas, a la corrosión y al desgaste. Destacan en entornos de alta temperatura y presión, soportando cargas de trabajo extremas. Se emplean comúnmente en industrias como la aeroespacial, la energética y la química, y son especialmente adecuados para la fabricación de componentes críticos como álabes de turbina y piezas de motor.

En la fundición de precisión, las aleaciones de cobalto se utilizan frecuentemente en la fundición a la cera perdida, lo que permite la producción de formas complejas y componentes de alta precisión. Su excelente comportamiento a altas temperaturas y su resistencia a la corrosión las convierten en materiales ideales para aplicaciones de alto rendimiento, garantizando un funcionamiento estable y una gran durabilidad a largo plazo.

Mediante procesos de fundición avanzados y un riguroso control de calidad, garantizamos que cada pieza de aluminio fundido presente una precisión, durabilidad y resistencia a la corrosión excepcionales.

Desde componentes complejos y precisos hasta estructuras grandes y pesadas, nuestras piezas fundidas de aluminio se pueden adaptar a sus necesidades específicas, proporcionando soluciones fiables para una variedad de aplicaciones exigentes.

En la fundición de precisión, las aleaciones de cobalto se utilizan frecuentemente en la fundición a la cera perdida, lo que permite la producción de formas complejas y componentes de alta precisión. Su excelente comportamiento a altas temperaturas y su resistencia a la corrosión las convierten en materiales ideales para aplicaciones de alto rendimiento, garantizando un funcionamiento estable y una gran durabilidad a largo plazo.

Mediante procesos de fundición avanzados y un riguroso control de calidad, garantizamos que cada pieza de aluminio fundido presente una precisión, durabilidad y resistencia a la corrosión excepcionales.

Desde componentes complejos y precisos hasta estructuras grandes y pesadas, nuestras piezas fundidas de aluminio se pueden adaptar a sus necesidades específicas, proporcionando soluciones fiables para una variedad de aplicaciones exigentes.

Grados comunes de materiales de aluminio y sus aleaciones

| Grado de aleación | Nombre de la aleación | Propiedades del material | Industria de aplicaciones | Widget de muestra |

| 1050 | Aluminio puro | Contenido de aluminio superior a 99%, excelente resistencia a la corrosión y conductividad eléctrica. | Electrónica, maquinaria, mecanizado de precisión | Carcasa eléctrica, carcasa de instrumentos, piezas pequeñas de fundición de precisión |

| 1060 | Aluminio puro | Buena soldabilidad y procesabilidad | Equipos electrónicos e instrumentos de precisión | Piezas de fundición de precisión, componentes estructurales internos de equipos electrónicos |

| 2024 | Aleación de aluminio y cobre | Alta resistencia, buena resistencia a la fatiga, baja resistencia a la corrosión | Industria aeroespacial y militar | Piezas de aviación, soportes de motores de aeronaves, fundiciones de precisión |

| 2011 | Aleación de aluminio y cobre | Excelente rendimiento de corte | Mecanizado de precisión | Piezas de alta precisión, cojinetes mecánicos, accesorios para motores |

| 3003 | Aleación de aluminio-manganeso | Buena resistencia a la corrosión y conformabilidad | Equipos electrónicos, fabricación de precisión | Fundición de precisión, disipadores de calor, componentes electrónicos |

| 3105 | Aleación de aluminio-manganeso | Mayor resistencia y resistencia a la corrosión | Maquinaria, automóviles | Piezas de fundición de precisión, componentes interiores de automóviles |

| 4032 | Aleación de aluminio y silicio | Buena resistencia al desgaste y al calor | Automóviles de alto rendimiento, maquinaria de precisión | Piezas de motor, componentes de motor de fundición de precisión |

| 4045 | Aleación de aluminio y silicio | Buena resistencia a la corrosión y conductividad térmica | Piezas de automóviles, intercambiadores de calor | Intercambiadores de calor para automóviles, piezas de radiador de precisión |

| 5052 | Aleación de aluminio y magnesio | Excelente resistencia a la corrosión por agua de mar y alta resistencia | Instrumentos de precisión, piezas de automoción de alta gama | Piezas de maquinaria de precisión, soportes de motor de automóvil |

| 5083 | Aleación de aluminio y magnesio | Resistencia a la corrosión extremadamente alta y gran resistencia | Industria automotriz, piezas de precisión militares | Soportes de motor, fundiciones de precisión |

| 7075 | aleación de aluminio-zinc | Alta resistencia, buena resistencia a la fatiga, difícil de procesar | Fabricación de automóviles, fundición de precisión militar | Soportes de motor, fundiciones de precisión |

| 7050 | aleación de aluminio-zinc | Resistencia a la corrosión y fuerza extremadamente altas | Fabricación de automóviles, fundición de precisión militar | Piezas de motor de automóviles, piezas estructurales de aviación |

| 8006 | Aleación de aluminio-zirconio | Buena conformabilidad y resistencia a la corrosión | Fundición de precisión, bienes de consumo | Fundición de precisión, componentes para dispositivos médicos, autopartes |

| 4032 | Aleación de aluminio de alta resistencia | Alta resistencia, buena resistencia al desgaste, resistencia a altas temperaturas | Automóviles de alto rendimiento, industria aeroespacial | Piezas resistentes a altas temperaturas, piezas para motores de competición |

Proceso de fundición del aluminio y sus aleaciones

Fundición de inversión

Aplicabilidad: La fundición a la cera perdida es muy adecuada para el cobalto y sus aleaciones. Gracias a su excelente comportamiento a altas temperaturas y su resistencia a la corrosión, este proceso permite producir con precisión piezas de aleación de cobalto con formas complejas, especialmente componentes de alta exigencia para las industrias aeroespacial y energética.

Ventajas:

• Alta precisión: Capaz de producir piezas fundidas con formas complejas y una precisión de detalle extremadamente alta.

• Excelente acabado superficial: Adecuado para piezas que requieren una calidad superficial estricta.

• Alta utilización del material: Adecuado para la producción de lotes pequeños y de alta precisión.

• Alta precisión: Capaz de producir piezas fundidas con formas complejas y una precisión de detalle extremadamente alta.

• Excelente acabado superficial: Adecuado para piezas que requieren una calidad superficial estricta.

• Alta utilización del material: Adecuado para la producción de lotes pequeños y de alta precisión.

Aplicaciones típicas: Álabes de turbina, componentes del núcleo del motor, piezas del intercambiador de calor.

Fundición en arena

Aplicabilidad: Adecuado para la producción en masa de componentes de aleación de cobalto de gran tamaño. Se utiliza ampliamente en componentes con requisitos de precisión relativamente bajos, pero con estrictos requisitos de resistencia a altas temperaturas y a la corrosión.

Ventajas:

• Rentabilidad: Los bajos costes de producción lo hacen adecuado para la producción en masa de componentes de tamaño mediano a grande.

• Flexibilidad dimensional: Capaz de producir piezas fundidas de gran tamaño con formas más simples.

• Resistencia a altas temperaturas: Capaz de cumplir con los requisitos de alta temperatura de las aleaciones de cobalto.

• Rentabilidad: Los bajos costes de producción lo hacen adecuado para la producción en masa de componentes de tamaño mediano a grande.

• Flexibilidad dimensional: Capaz de producir piezas fundidas de gran tamaño con formas más simples.

• Resistencia a altas temperaturas: Capaz de cumplir con los requisitos de alta temperatura de las aleaciones de cobalto.

Aplicaciones típicas: Álabes de turbinas de gas, componentes de equipos químicos y carcasas de maquinaria.

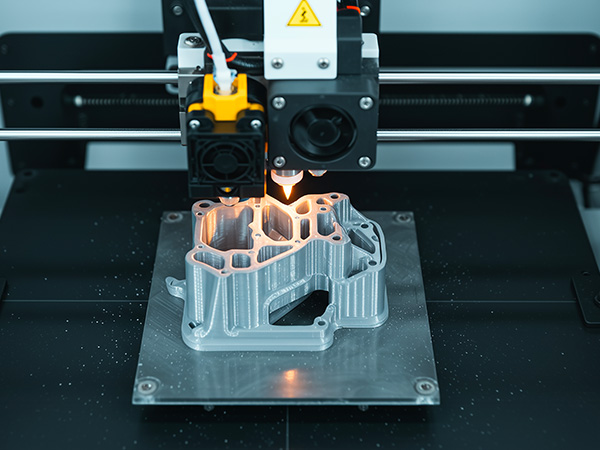

Impresión 3D

Aplicabilidad: Adecuado para piezas de aleación de cobalto personalizadas en lotes pequeños, especialmente donde se requieren prototipos rápidos, geometrías complejas y diseños de alta precisión.

Ventajas:

• Respuesta rápida: Se pueden producir prototipos o lotes pequeños rápidamente en función de los requisitos de diseño.

• Gran libertad de diseño: Se pueden producir estructuras complejas que son imposibles con los procesos de fundición tradicionales.

• Reducción de los pasos de procesamiento: La pieza final se puede imprimir directamente, ahorrando costes de procesamiento posteriores.

• Respuesta rápida: Se pueden producir prototipos o lotes pequeños rápidamente en función de los requisitos de diseño.

• Gran libertad de diseño: Se pueden producir estructuras complejas que son imposibles con los procesos de fundición tradicionales.

• Reducción de los pasos de procesamiento: La pieza final se puede imprimir directamente, ahorrando costes de procesamiento posteriores.

Aplicaciones típicas: Componentes aeroespaciales de precisión, piezas especiales personalizadas y piezas de alta complejidad.

Comience su proyecto con Leierwo

1. Envíe su consulta

Envíe sus dibujos CAD y archivos 3D por correo electrónico, especificando el grado del material, la cantidad del pedido, el acabado de la superficie o cualquier otro detalle relevante.

2. Cálculo de costes

En cuanto recibamos su diseño, nuestro equipo de ingenieros evaluará detenidamente los planos y calculará el precio en función de los costes de producción reales lo antes posible.

3. Inicio de la producción

Una vez aprobado el precio, nuestro equipo de producción preparará los materiales y programará la producción con prontitud.Leierwo siempre garantiza la entrega a tiempo.

4. Organizar la entrega

Una vez finalizada la producción, le proporcionaremos los detalles del embalaje y organizaremos el envío por mar o aire. Todos los pedidos se pueden enviar a cualquier parte del mundo.

PREGUNTAS FRECUENTES

P1. ¿Es usted una empresa comercial o un fabricante?

P2. ¿Pueden cotizar basándose en dibujos 3D?

P3. ¿Cómo se gestionan las RFQ (solicitudes de cotización)?

P4. ¿Cuál es su plazo de entrega típico?

P5. ¿Ofrecen muestras? ¿Son gratuitas?

P6. ¿Qué métodos de pago aceptan?

P7. ¿Cómo se garantiza el control de calidad?

P8. ¿Sus productos vienen con garantía?

P9. ¿Cómo ve su relación con los clientes?