Pump Manufacturing: How Pumps Are Made Step by Step

¡Bienvenido a mi blog!

¡Me encanta tenerte aquí! Antes de profundizar en el contenido, me encantaría que me acompañaras en mis redes sociales. Es donde comparto información adicional, conecto con nuestra increíble comunidad y te mantengo al tanto de las últimas noticias. Así es como puedes mantenerte conectado:

📘 Facebook: Shanghai Leierwo Industria Comercio Co., Ltd.

¡Ahora, emprendamos este viaje juntos! Espero que el contenido aquí te resulte no solo revelador, sino también inspirador y valioso. ¡Comencemos!

Tabla de contenido

Key Takeaways

- Learn the complete end-to-end pump manufacturing process, focusing on key components such as pump bodies, impellers, sleeves, and shafts.

- Understand material selection, including stainless steel, carbon steel, bronze, and high-alloy options for corrosion and wear resistance.

- Compare casting methods (investment casting vs sand casting) and precision machining requirements for reliability.

- Discover quality control checkpoints, including non-destructive testing, dimensional inspection, and performance validation.

- Get answers to real Google-style questions in the FAQ section, designed to match modern search intent.

Introducción

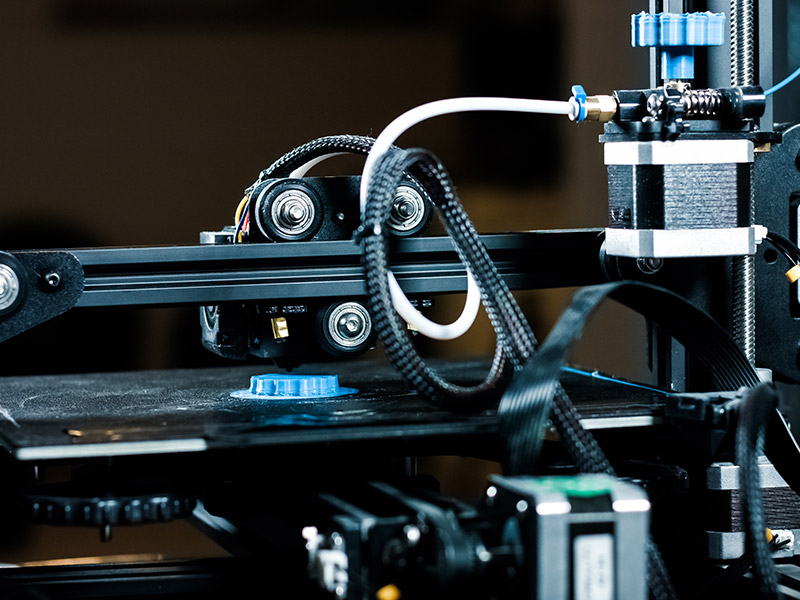

Imagine a pump running 24/7 in a chemical plant, a water treatment facility, or a mining operation. It is not just a mechanical device; it is a core component of industrial safety and efficiency. When a pump fails, it can cause production stoppage, costly repairs, or even catastrophic accidents. The secret to long-lasting pump performance lies not in the brand name, but in how the pump is made, especially the manufacturing quality of its critical parts.

Pump manufacturing is a precise blend of material science, fluid dynamics, casting technology, and machining accuracy. It starts with design and ends with performance validation, and every step impacts the final reliability. In this guide, we will break down the pump manufacturing process into detailed stages, focusing on the manufacturing of pump parts, and provide industry insights and data to help you understand what truly matters when selecting a pump manufacturer.

Design and Engineering: Building the Pump from the Inside Out

The Role of Requirements in Pump Design

Before any metal is cast or machined, engineers must define the pump’s intended environment. Key factors include fluid type, temperature, pressure, flow rate, and expected lifespan. These parameters guide the entire manufacturing process.

Using CAD and CFD for Optimal Design

Modern pump manufacturing relies heavily on computer-aided design (CAD) and computational fluid dynamics (CFD). CFD helps optimize internal flow channels to reduce turbulence, minimize cavitation, and improve efficiency. A well-designed pump body and impeller can increase efficiency by 5% to 15% compared to a poorly designed one.

How Impeller Design Influences Efficiency

The impeller is the heart of the pump. Its blade geometry directly affects fluid flow. A slight error in blade curvature can cause significant efficiency loss. For example, an impeller with 0.2 mm deviation in blade profile may lead to increased vibration and reduced service life.

Material Selection: The Foundation of Pump Reliability

Why Material Selection Is Critical

Pump components face harsh conditions: corrosion, abrasion, high pressure, and temperature changes. The wrong material can lead to rapid wear, cracking, or corrosion, shortening the pump’s service life.

Common Materials Used in Fabricación de bombas

Stainless Steel Series

- 316/316L: Excellent resistance to acids, alkalis, and chloride ions. Widely used in chemical pumps, seawater pumps, and food-grade applications.

- 2205 Duplex Steel: High strength and superior pitting resistance. Ideal for seawater and harsh chemical environments.

- 304/304L: Common in water treatment and general-purpose applications.

Carbon Steel Series

- 1045: Good mechanical strength for pump shafts and casings in non-corrosive environments.

- 4130: Used in high-pressure and high-temperature pump components due to high strength and toughness.

Special Alloy Series

- C95400 Bronze: Excellent wear resistance and self-lubrication, ideal for sleeves and sliding components in seawater pumps.

- Cobalt Alloys (Co6): Used for high-wear and high-temperature impellers or sealing surfaces.

The Industry Standard: Corrosion Resistance and Wear Resistance

In pump manufacturing, materials must withstand corrosion and wear simultaneously. According to industry reports, corrosion-related failure accounts for about 30% of pump failures, while wear and abrasion account for another 25%. Therefore, selecting the right alloy is essential for longevity.

Casting Processes: How Pump Components Take Shape

Investment Casting: Precision for Complex Flow Parts

Investment casting is the preferred method for manufacturing complex pump parts like impellers. It provides high accuracy and excellent surface finish.

Why Investment Casting Works for Impellers

Impellers require precise blade geometry and smooth surfaces to reduce fluid resistance. Investment casting can achieve blade profile accuracy of ±0.1 mm and surface finish of Ra3.2 µm or better, which significantly improves hydraulic efficiency.

Sand Casting: Cost-Effective for Pump Bodies

Sand casting is widely used for pump bodies and large components due to its cost-effectiveness and flexibility.

Why Sand Casting Is Suitable for Pump Bodies

- Lower production cost

- Suitable for large and heavy components

- Fast mold production and short cycle time

3D Printing and Hybrid Manufacturing

With the rise of additive manufacturing, some pump manufacturers use 3D printing for prototypes or complex internal structures. Hybrid manufacturing combining 3D printing with traditional casting can reduce development time and improve design flexibility.

Machining: Turning Castings into Precision Components

CNC Machining for Critical Surfaces

Casting alone cannot achieve the precision required for pump seals and shaft connections. CNC machining is essential for these areas.

Precision Requirements in Pump Manufacturing

- Shaft concentricity ≤ 0.01 mm

- Sealing surface flatness within 0.02 mm

- Surface finish often needs to meet Ra0.8 or better for sealing surfaces

Balancing and Alignment

Dynamic balancing of the impeller and accurate alignment of the shaft reduce vibration and noise. A well-balanced impeller can reduce vibration by 40% or more, significantly improving pump life.

Key Component Manufacturing: Detailed Breakdown

Pump Body Manufacturing

The pump body is the primary pressure-bearing structure. It must be cast with uniform wall thickness and accurate internal flow channels. Common defects include porosity, uneven thickness, and misalignment.

Impeller Manufacturing

Impellers are often made by investment casting due to their complex blade geometry. The impeller must be strong, corrosion-resistant, and dimensionally accurate.

Sleeve and Bearing Manufacturing

Sleeves and bearings must withstand wear and reduce friction. Materials like bronze or special alloys are used. Surface treatment can further improve durability.

Shaft Manufacturing

Pump shafts must resist torsion and fatigue. Precision machining and heat treatment improve strength and fatigue life.

Quality Control: Ensuring Reliability Before the Pump Leaves the Factory

Casting Inspection

Casting defects such as porosity, cracks, and inclusions can lead to failure. Non-destructive testing (NDT) methods such as ultrasonic testing and X-ray inspection are widely used.

Dimensional Inspection

Coordinate measuring machines (CMM) measure critical dimensions. Dimensional accuracy ensures proper assembly and prevents leakage.

Surface Treatment Inspection

Surface finish and coating quality are inspected to ensure corrosion and wear resistance.

Performance Testing: Validating Real-World Reliability

Prueba de presión

Pressure testing ensures the pump can withstand its rated pressure. Many manufacturers conduct hydrostatic tests at 1.5 times the rated pressure.

Flow Testing

Flow tests verify the pump’s flow rate and head meet design requirements. The performance curve must be within acceptable tolerance.

Vibration and Noise Testing

Excessive vibration indicates misalignment or imbalance. Noise testing helps identify cavitation or mechanical issues.

Comparison: Investment Casting vs Sand Casting vs 3D Printing

When to Choose Fundición de inversión

Best for complex impellers and high-precision parts. It provides excellent accuracy and surface finish.

When to Choose Fundición en arena

Best for large pump bodies and cost-effective mass production.

When to Use Impresión 3D

Best for rapid prototyping, complex internal geometries, and customized small-batch production.

Summary Table: Casting Comparison

| Casting Type | Mejor para | Precisión | Costo | Typical Parts |

|---|---|---|---|---|

| Fundición de inversión | Complex impellers | High (±0.1 mm) | Más alto | Impellers, small casings |

| Fundición en arena | Pump bodies | Medio | Más bajo | Pump housings, large casings |

| Impresión 3D | Prototypes, complex internal parts | Alto | Alto | Prototypes, specialized components |

Industry Data and Expert Insights

Real-World Data on Pump Failures

According to industry statistics, the top causes of pump failure include:

- Improper material selection (30%)

- Wear and abrasion (25%)

- Corrosion (20%)

- Misalignment and imbalance (15%)

- Sealing failure (10%)

This highlights why pump manufacturing quality and material selection are so critical.

What Experts Say

Industry experts emphasize that pump manufacturing is not just about casting and machining, but about system-level optimization. A well-designed pump with poor manufacturing will still fail, while a well-manufactured pump can outperform many standard designs.

Practical Buyer’s Checklist for Pump Manufacturing

How to Choose a Reliable Pump Manufacturer

When selecting a pump manufacturer, consider the following:

- Material expertise: Can they recommend the right alloy for your application?

- Casting capabilities: Do they offer investment casting and sand casting?

- Machining precision: Do they have advanced CNC equipment?

- Quality control: Do they perform NDT, CMM inspection, and performance testing?

- After-sales support: Do they offer maintenance guidance and spare parts?

Common Mistakes Buyers Make

- Choosing a pump based solely on price

- Ignoring material compatibility

- Overlooking machining accuracy and quality control

- Underestimating the impact of impeller design

Conclusión

Pump manufacturing is a complex process that requires expertise in design, materials, casting, machining, and quality control. The reliability of a pump depends largely on the manufacturing quality of its core components, especially the pump body and impeller. By understanding the manufacturing process and choosing a manufacturer with strong capabilities, you can ensure long-term performance and avoid costly failures.

If you want, I can also help you:

- generate SEO meta title/description for this article

- create a structured table of contents

- translate the article into Chinese or bilingual format

- rewrite it for specific pump types (centrifugal, slurry, chemical, etc.)

Just tell me what you need next.

PREGUNTAS FRECUENTES

What are the main parts of a pump and how are they made?

The main parts include pump body, impeller, shaft, sleeve, and seals. Pump bodies often use sand casting, while impellers use investment casting. Shafts and sealing surfaces are machined precisely.

How do I choose the right material for pump components?

Choose materials based on fluid type and operating environment. Stainless steel is common for corrosive fluids, while bronze and cobalt alloys are used for wear resistance.

What is the difference between pump casting and pump machining?

Casting forms the basic shape of components, while machining ensures precision and sealing performance. Both are essential for reliable pump manufacturing.

Why is impeller accuracy so important?

Impeller accuracy affects fluid dynamics and efficiency. Even small deviations can cause turbulence and reduce pump performance.

How long does a well-made pump last?

Under normal conditions, a well-manufactured pump can last 5–15 years. With high-grade materials and precision manufacturing, the lifespan can exceed 20 years in some applications.

Categorías de productos

- Piezas de válvulas

- Piezas de la bomba de agua

- Piezas de la caja de cojinetes

- Piezas de fundición a presión

- Productos para bombas de acero inoxidable

- Productos para bombas de hierro fundido

- Piezas de válvulas para automóviles

- Recambios para automóviles

- Piezas de válvulas para uso civil

- Piezas de bomba de vacío KF