How 3D Printing Innovations Cut Production Costs for Large-Scale Casting

¡Bienvenido a mi blog!

¡Me encanta tenerte aquí! Antes de profundizar en el contenido, me encantaría que me acompañaras en mis redes sociales. Es donde comparto información adicional, conecto con nuestra increíble comunidad y te mantengo al tanto de las últimas noticias. Así es como puedes mantenerte conectado:

📘 Facebook: Shanghai Leierwo Industria Comercio Co., Ltd.

¡Ahora, emprendamos este viaje juntos! Espero que el contenido aquí te resulte no solo revelador, sino también inspirador y valioso. ¡Comencemos!

Tabla de contenido

Key Takeaways

- Cut raw material and production costs using strategic 3d printing innovations in batch manufacturing.

- Industry data shows material use efficiency up to 90% y lead times reduced from months to weeks.

- Metal additive manufacturing market growth projections illustrate adoption for high-volume industrial parts.

- Specific cost drivers in automotive, aerospace, and tooling highlight when 3D printing becomes more economical than traditional casting.

- A comparison table helps buyers assess cost factors across technologies.

- El FAQ section answers questions in search-friendly style to aid decision makers.

A Manufacturing Revolution: Why 3D Printing Innovations Matter for Big Buyers

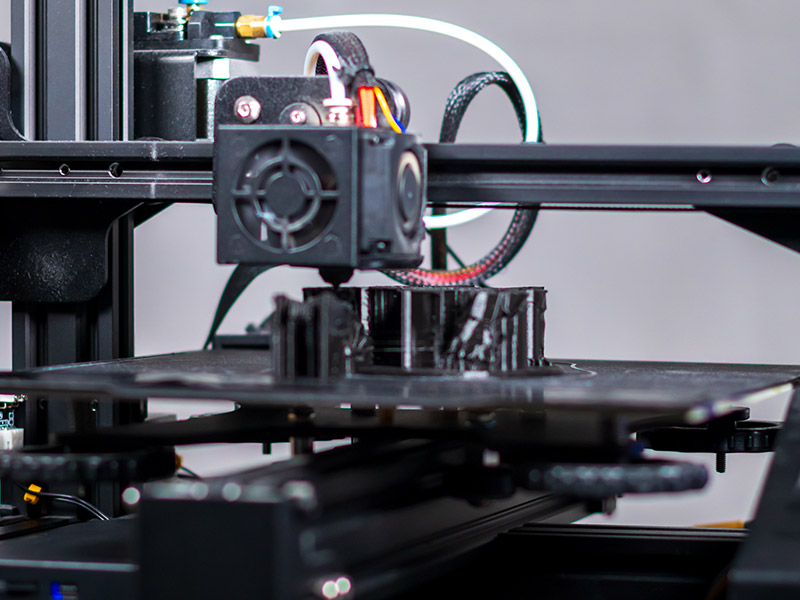

Global manufacturing is shifting. Traditional casting and machining still rule high-volume parts, but 3d printing innovations are rapidly becoming cost-competitive—even for high-volume runs—because they reduce waste, streamline complex geometries, and significantly shorten lead times. Market projections substantiate this shift: the global additive manufacturing market is expected to reach $362 billion by 2026, up from about $200 billion in 2023, with double-digit CAGR.

Large industries such as aerospace, automotive, and heavy equipment are now looking at 3D printing not just for prototypes but as integrated production technology. Metal additive manufacturing is growing particularly fast—over 50% of aerospace parts manufacturers are already using it for structural components—a clear sign that innovations are cutting both weight and cost.

How 3D Printing Innovations Reduce Material Waste and Cost

Additive Manufacturing vs Subtractive Methods

Why Traditional Manufacturing Produces So Much Waste

Traditional subtractive manufacturing (milling, turning, grinding) begins with a solid block. This creates significant material loss because most of the raw material is cut away.

Typical waste levels:

- CNC machining: 50%–80% material waste

- Casting with machining: 30%–60% waste depending on complexity

- High precision parts: even higher due to tight tolerances

How 3D Printing Innovations Achieve Higher Material Utilization

In contrast, additive manufacturing only uses material where it is needed. This leads to:

- Material utilization of 90–95%

- Waste reduction by up to 90% compared to subtractive methods

- Reduced raw material purchase and inventory

- Less scrap disposal cost

Real-world Example:

A manufacturer printing titanium aerospace brackets reduced material waste from 70% to 8%, saving millions in raw material costs over a year.

List: Material Efficiency Benefits of 3D Printing Innovations

- Reduced raw material purchase costs

- Less scrap disposal expense

- Lower inventory and storage needs

- Less machining time and tool wear

- Higher ability to reuse unused powder or filament

3D Printing Innovations Shorten Lead Times and Speed Production

Prototyping Now Takes Days, Not Months

Traditional tooling for molds and dies can take weeks to months. This is especially true in industries like automotive and aerospace, where tool complexity is high.

With 3D printing innovations:

- CAD → physical prototype in hours or days

- Multiple iterations without retooling

- Faster validation and testing cycles

Estudio de caso:

A European automotive supplier reduced prototype lead time from 10 weeks to 7 days using metal 3D printing for production-grade fixtures.

Production Speed and Automation

Modern industrial 3D printers include features such as:

- Automatic powder handling

- Multi-laser systems

- AI process optimization

- In-line monitoring and quality control

This reduces manual labor and increases throughput.

According to industry surveys:

- 67% of companies use additive manufacturing for production parts, not just prototypes.

List: Speed Benefits of 3D Printing Innovations

- Shorter lead time for tooling and prototypes

- Faster ramp-up for new products

- Reduced downtime due to rapid replacement parts

- On-demand manufacturing reduces inventory pressure

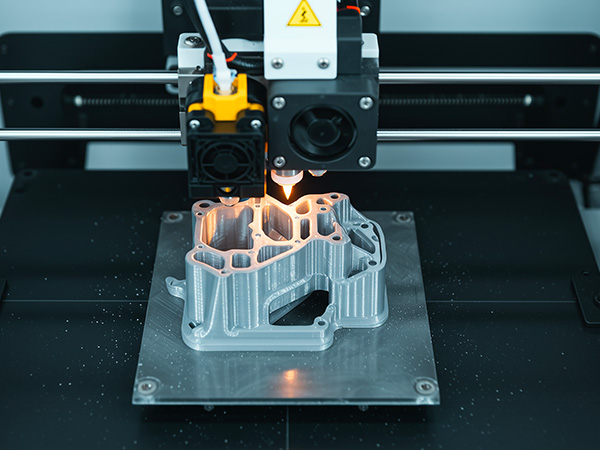

Metal 3D Printing Innovations Lower Costs in High-Volume Casting

Metal Printing vs Traditional Casting: Cost Drivers

Metal additive technologies such as SLM (Selective Laser Melting) y DED (Directed Energy Deposition) make complex parts that would require expensive tooling or multiple cast components. These innovations have shown cost savings in multiple sectors:

- Aerospace: Structural parts printed with optimized designs can weigh up to 28% less, directly reducing fuel and operating costs in service.

- Automotive: Metal printed parts are reducing part count and enabling light weighting, with some carmakers adopting them for production components.

- Tool & Mold Making: Hybrid 3D printed sand cores or molds reduce lead time and eliminate multiple machining steps.

Note: 3D printing costs for metal remain higher than polymer printing due to material cost and equipment capital, but the return on investment (ROI) often outweighs these expenses when complexity, assembly, and quality improvements are considered.

Real-World Data: How Cost Reductions Add Up

Below is a breakdown of cost advantages seen by large industrial buyers adopting 3d printing innovations over traditional approaches.

| Cost Category | Traditional Casting / Machining | With 3D Printing Innovations |

|---|---|---|

| Residuos de materiales | 50%–80% | 5%–10% |

| Lead Time (tooling) | Weeks–Months | Hours–Days |

| Part Consolidation | Multiple parts | Single printed part |

| Tooling Costs | Alto | Mínimo |

| Labor Intensity | Alto | Lower with automation |

| Customization Cost | Very high | Low per batch |

Estimates are based on industry reports and structuring of additive vs subtractive workflows.

Industry Applications Where 3D Printing Innovations Drive Big Savings

Aerospace and Defense

The aerospace industry has been one of the earliest adopters of metal 3D printing. According to industry statistics:

- Over 55% of 3d printing in aerospace is metal powder-based for structural and critical components.

- Weight reductions of up to 28% are typical for optimized parts, yielding fuel savings over the life of an aircraft.

These innovations make complex geometries economically viable and reduce assembly labor dramatically.

Automotive OEMs

Major automakers are incorporating additive manufacturing:

- Over 25% of new vehicle parts may involve some 3D printed components by 2025.

- Custom fixtures for production lines, prototypes, and even some end-use parts are being printed to reduce downtime and tooling expense.

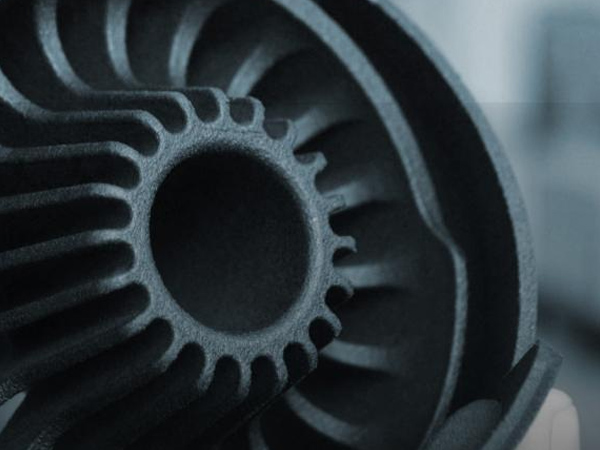

Tooling and Foundry

3d printing innovations enable production of:

- Complex sand molds at fraction of cost

- Rapid adjustment of patterns without new tooling

- Topology-optimized tool inserts

Companies report lead time cuts from months to weeks, and lower scrap costs, especially for large casting cores.

Key Cost Drivers and How to Control Them

Material Costs

Metal powders remain a leading cost factor. For example, high-grade aerospace powders can be more than 40% the cost of finished parts in some workflows. However, as supply grows and domestic manufacturers emerge, prices have fallen. A major Chinese provider saw prices drop from ~¥1.44M/ton to ~¥781,900/ton over two years, while margins increased due to scale.

Machine Acquisition vs ROI

Metal 3D printers remain expensive—often 2.5× more than polymer machines—but higher throughput and automation can deliver ROI within set production lines for high-value parts.

Skill and Training

Acerca de 43% of manufacturers cite consistency and skilled labor shortage as adoption barriers. Investment in training and process control software is critical for cost stability.

Choosing the Right 3D Printing Technology for High-Volume Casting Needs

SLA, SLS, FDM, Metal Printing

Each technology fits a different need:

- SLA: Excellent for precise patterns used in casting (lost wax patterns).

- SLS: Great for durable polymer parts and functional prototypes.

- FDM: Cost-effective for jigs, fixtures, and tooling aids.

- Metal (DMLS/SLM/DED): Best for structural, high-strength parts and direct part production.

Industrial Scaling Considerations

When scaling, buyers should consider:

- Machine uptime and maintenance

- Material inventory logistics

- Part finishing and post-processing

- Integration with existing assembly lines

Best Practices for Implementing 3D Printing Innovations

Standardize Design and Workflow

Use design for additive manufacturing (DfAM) principles to reduce part count, minimize support structures, and optimize geometry.

Leverage Simulation and AI

AI-driven simulation can optimize print parameters and reduce trial-and-error, cutting time and failed prints.

Integrate Quality Controls

Inline monitoring tools help maintain tolerances and consistency, particularly for critical aerospace or automotive parts.

Final Conclusion

For procurement professionals in high-volume manufacturing sectors, 3d printing innovations are no longer experimental. They are strategic tools that reduce production costs, improve part performance, and unlock design freedom. With market growth projected into the hundreds of billions and adoption growing fastest in aerospace, automotive, and tooling, companies that integrate additive manufacturing effectively can gain a competitive advantage.

By leveraging real-world cost data, optimizing part workflows, and choosing the right technology for your volume needs, large buyers can not only reduce unit cost but also transform their manufacturing ecosystem.

PREGUNTAS FRECUENTES

What are the main cost savings from 3D printing innovations?

Cost savings come from reduced waste, no tooling, shorter lead times, and part consolidation.

Can 3D printing be used for high-volume production?

Yes—especially for complex, highly customized parts or where printing replaces multiple assembly steps.

How much can 3D printing reduce material waste?

Additive processes can reduce waste by up to 90% compared to subtractive methods.

Is metal 3D printing worth the investment?

For industries like aerospace, automotive, and tooling, the upfront cost is justified by part performance, weight savings, and lifecycle cost reduction.

What are the main barriers to adoption?

Material cost, machine cost, and skilled labor shortages are common barriers.

How do 3D printing innovations affect product quality?

They improve quality by enabling consistent geometry, reducing human error, and allowing precise control over microstructures—especially in metal printing with controlled cooling and scanning strategies.

Does 3D printing reduce lead time for mass production?

Yes, especially for tooling, molds, and prototype-to-production transition. Lead time can shrink from months to weeks, and sometimes days for simple components.

How much does 3D printing cost per part compared to casting?

It varies widely. For complex parts or low-to-mid volume runs, 3D printing can be cheaper due to no tooling and less assembly. For high-volume simple shapes, casting remains more cost-effective.

Are there any environmental benefits of 3D printing innovations?

Yes. 3D printing reduces material waste, lowers energy use for some processes, and can enable lighter products—leading to reduced fuel consumption in aerospace and automotive.

What is the best 3D printing technology for industrial casting?

For metal casting and high strength parts, SLM/DMLS is often best. For molds and patterns, SLA and SLS are widely used due to accuracy and surface finish.

How do 3D printing innovations affect supply chain management?

They reduce dependency on long supply chains by enabling local manufacturing, on-demand production, and shorter inventory cycles—especially valuable in uncertain markets.

What kind of post-processing is required after 3D printing?

It depends on the technology. Metal parts often need heat treatment, machining, or surface finishing. Polymer parts may require sanding, coating, or curing.

Is 3D printing suitable for regulated industries like aerospace or medical?

Yes, but it requires strict quality control, traceability, and certification. Many aerospace companies already use metal 3D printing for certified components.

Categorías de productos

- Piezas de válvulas

- Piezas de la bomba de agua

- Piezas de la caja de cojinetes

- Piezas de fundición a presión

- Productos para bombas de acero inoxidable

- Productos para bombas de hierro fundido

- Piezas de válvulas para automóviles

- Recambios para automóviles

- Piezas de válvulas para uso civil

- Piezas de bomba de vacío KF