¿Cuáles son las aplicaciones del acero inoxidable 304 en la fundición?

Tabla de contenido

Introducción

When designing metal parts through casting, choosing the right alloy is crucial. Among the many stainless steel grades, Acero inoxidable 304 stands out as a highly versatile option. In this article, we explore what the applications of 304 stainless steel in casting are, why engineers choose it, its limitations, and how it is actually used in different industries. We will also include technical tables, real data, and a FAQ section to address common queries.

Por qué Acero inoxidable 304 Is Widely Used in Casting

Before diving into applications, it’s necessary to understand what makes 304 stainless steel attractive for casting applications.

Key Material Properties of Acero inoxidable 304

- 304 stainless steel is an austenitic stainless steel with roughly 18 % chromium and 8 % nickel (commonly called “18-8”)

- In the annealed state, it is essentially nonmagnetic, though cold work may induce slight magnetism

- Its mechanical strength in typical annealed form: ultimate tensile strength ~515 MPa, yield strength ~205 MPa, elongation ~70 %

- Density ≈ 7.93 g/cm³

- Thermal conductivity is modest (around 16.2 W/m·K)

- It exhibits good oxidation resistance up to ~870 °C intermittently, and continuous performance to ~925 °C, but is not ideal for long-term service in 425–860 °C in aqueous environments

These properties make it a balanced alloy: not the absolute best in each metric, but well-rounded, cost-effective, and manufacturable.

Castability and Fabrication Advantages

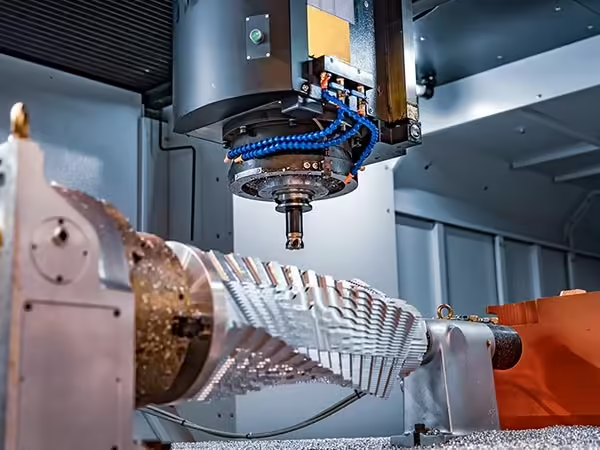

- 304 stainless steel is fairly amenable to casting processes such as investment casting or sand casting (in its cast equivalent CF8)

- It welds reasonably well and is formable, giving designers flexibility in finishing or joining cast parts

- Surface treatments like passivation, electropolishing, and mirror polishing can enhance corrosion resistance and appearance for cast 304 parts

- Its cost, relative to more exotic stainless grades (e.g. 316), is favorable in many applications where extreme corrosion resistance is not required

Given those advantages, 304 stainless steel becomes a strong candidate for many casting use cases.

Major Application Areas of Acero inoxidable 304 en Casting

Below, we detail specific sectors and use cases where 304 Stainless Steel castings are commonly used.

Food and Beverage & Sanitary Equipment

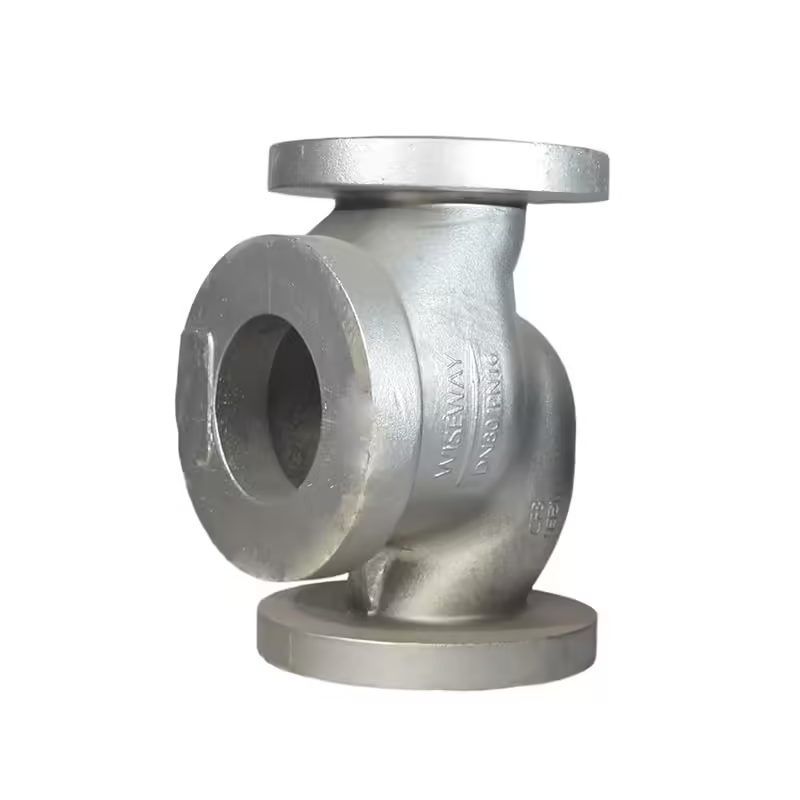

One of the hallmark uses is in equipment that requires hygiene, corrosion resistance, and durability: tanks, piping, valves, fittings, pumps. In food and pharmaceuticals, cast 304 parts are often preferred because the alloy resists oxidation and is easy to clean.

Example: in dairy or brewing plants, cast 304 components like valves are common because they must handle cleaning, mild acids, and moisture.

Chemical, Petrochemical & Process Industry

304 stainless steel castings are used for reactors, pressure vessels, pipe fittings, pump bodies, and valve housings in chemical plants, where moderate corrosion resistance is necessary. It is, however, less resistant to chloride attack than higher alloys (see caution later).

Marine & Water Handling Components

In marine or near-coastal environments, 304 castings serve in deck hardware, fittings, cuerpos de bomba, and pipe components. However, they are susceptible to pitting and crevice corrosion in high chloride (saltwater) exposure, so designers often weigh alternatives (e.g. 316).

Automotor and Exhaust / Hardware Parts

304 castings appear as brackets, housings, exhaust manifolds or parts that require moderate corrosion resistance under heat and environmental exposure. The balance of cost and performance often makes it acceptable in non-extreme automotive zones.

Architecture, Decorative and Structural Cast Parts

Because of good corrosion resistance and visual appeal when surface-treated, 304 castings may be used for architectural fittings, façade elements, railings, decorative trim, and outdoor structural components.

Power, Hydroelectric, and Turbine Components

In certain water-exposed or hydroelectric systems, 304 cast parts (e.g. impellers, turbine components, structural supports) may be used given its corrosion resistance in freshwater environments .

Medical, Laboratory & Cleanroom Equipment

For parts that require cleanliness, corrosion resistance, and sterilization, cast 304 stainless steel parts find use in lab equipment, medical devices, and cleanroom infrastructure.

Oil & Gas, but with Limitations

In oil, gas, and petrochemical settings, 304 castings may be used in non-critical zones or as backup parts, but more aggressive alloys (316, duplex, superalloys) tend to dominate where there are chloride or sulfur exposures.

Comparative Table of Cast Acero inoxidable 304 vs Alternatives

Here is a mid-section table comparing typical performance metrics and constraints of cast 304 stainless steel against some alternatives (e.g. 316, duplex) in casting applications. This helps in deciding where 304 is suitable or insufficient.

| Metric / Parameter | Cast 304 Stainless Steel | Cast 316 Stainless Steel | Duplex Stainless Steel (e.g. 2205) |

|---|---|---|---|

| Corrosion resistance in chloride environments | Fair; risk of pitting/crevice, especially >150–400 mg/L Cl⁻ | Superior, especially in chloride, marine or harsh chemical environments | Very high; excellent resistance to stress corrosion and pitting |

| Cost (material & alloying) | Lower among stainless high alloys | Higher than 304 | Higher still, more complex |

| Mechanical strength | Good, moderate | Similar or slightly higher | Higher yield/performance |

| Castability and manufacturability | Bien | Slightly more challenging due to composition | More complex process |

| Weldability and post-treatment | Good, especially in less aggressive environment | Good, but sensitization risk in some conditions | More demanding, but gives high performance |

| Temperature performance | up to ~870–925 °C intermittently | Similar or slightly better in some cases | Reliable in many elevated-temperature roles |

| Best application zones | Food, general chemical, architecture, moderate environments | Marine, harsher chemical zones, aggressive chloride exposure | High-stress, high corrosion, critical environments |

From the table, one sees that 304 stainless steel castings shine when the environment is moderate, not extremely aggressive, and cost matters.

Design Considerations & Limitations

While 304 offers many advantages, practical design must account for its limitations.

Corrosion Risks & Chloride Sensitivity

304 stainless steel is vulnerable to pitting, crevice corrosion, and stress corrosion cracking under aggressive chloride environments. In warm chloride solutions (>150–400 mg/L), risk increases. Designers may avoid 304 in marine or high-saline zones without mitigations.

Temperature and Thermal Stress

Though 304 tolerates intermittent heat up to ~870 °C, long-term exposure in the 425–860 °C range in aqueous or corrosive conditions may degrade corrosion resistance, especially if sensitization occurs or grain boundary carbides form.

Sensitization, Welding, and Intergranular Corrosion

After welding or prolonged high-temperature exposure, chromium carbide precipitation can cause sensitization, reducing corrosion resistance at grain boundaries. Use low-carbon variants (304L) or control post-heat treatment when necessary.

Machinability and Casting Defects

While machinable, stainless steels tend to work harden; care must be taken with tooling. Casting defects like porosity, shrinkage, inclusion or segregation are common challenges. In thicker castings, internal stresses or uneven cooling may cause cracking or distortion.

Surface Finishing and Post-processing

To improve corrosion resistance and aesthetics, cast parts often require passivation, electropolishing or surface finishing. Poor surface finish or retained inclusions may compromise performance.

Cost vs Performance Trade-off

In environments that demand superior corrosion resistance, higher alloys (e.g. 316, duplex) may be more cost-effective over life cycle even though initial material cost is higher.

Practical Examples & Real Use Cases

Here are several real-world examples or typical uses of cast 304 stainless steel in operation:

Pump / Valve Housings

In water treatment systems or chemical processes, cast 304 housings for pumps or valves are common because they contact fluids, require corrosion resistance, and often require customized shapes.

Food Processing Machinery

Cast 304 parts are used in mixers, conveyors, sanitary valves, connectors, fittings in food/brewery/dairy equipment. Their corrosion resistance and ease of cleaning make them suitable.

Marine Hardware (Limited Zones)

In less aggressive marine zones (e.g. above waterline, fresh water docks), cast 304 fittings and structural elements see use—but designers must consider salt exposure.

Architectural & Decorative Castings

Columns, façade decorative panels, signage elements, sculptural castings may use cast 304 due to its resistance to weathering and good surface finish.

Utility & Infrastructure Components

Handrails, rail fittings, connectors, outdoor structural parts near urban or coastal settings sometimes use cast 304 stainless parts.

Heat Exchanger & Boiler Components

In moderate temperature fluid circuits (not extremely high temperature or highly corrosive fluids), cast 304 is used in exchangers and boiler fittings.

Best Practices for Applying Acero inoxidable 304 in Castings

Below are design and process best practices to maximize performance of 304 castings.

Use Proper Alloy Variants

When welding or prone to sensitization, opt for 304L (low-carbon) or dual-certified 304/304L to reduce intergranular corrosion risk.

Control Cooling and Solidification

Uniform cooling helps reduce residual stresses, segregation, and porosity. Use gating and riser designs optimized for stainless steel behavior.

Post-Casting Heat Treatment & Annealing

Solution annealing (heating to ~1010–1120 °C and rapid cooling) helps dissolve carbides and restore corrosion resistance.

Surface Treatment & Passivation

After machining or surface exposure, passivation (e.g. nitric acid, citric acid) helps form a clean chromium oxide film. Electropolishing further smooths micro-surface and improves corrosion resistance.

Design for Drainage, Avoid Crevices

In cast parts intended for fluid contact, avoid geometries that trap fluid, debris, or create stagnant zones. Smooth transitions help reduce crevice corrosion.

Inspection and Quality Control

Non-destructive testing (e.g. X-ray, ultrasonic) is recommended for critical cast parts. Inspect for porosity, cracks, inclusions, and overall casting integrity.

Environment Matching

Before choosing 304, assess the actual operating environment: chloride levels, temperature cycles, chemical exposure. If aggressive, consider using higher alloy.

Conclusión

In summary, 304 Stainless Steel castings play a valuable role across many industries — food & beverage, chemical processing, architecture, infrastructure, and more — especially in environments that are not extremely aggressive. Its balanced properties, widespread availability, and favorable cost make it a go-to alloy for many casting projects. However, it is not a panacea: designers must carefully consider chloride exposure, sensitization risk, surface finish, and post-treatment. By following best practices in design, heat treatment, finishing, and inspection, many of the limitations can be mitigated.

If you’re evaluating cast stainless options, 304 is a solid baseline to consider — and comparing it with 316 or duplex on a case-by-case basis is wise.

PREGUNTAS FRECUENTES

Q1: Can I use acero inoxidable 304 castings in saltwater environments?

It’s doable in mild or splash zones, but not recommended in full immersion or highly saline settings due to pitting and crevice corrosion risks. For marine or chloride-rich environments, 316 or duplex alloys are safer choices.

Q2: What’s the difference between 304 cast stainless and 304L for cast parts?

304L is a low-carbon version designed to reduce chromium carbide precipitation upon welding or high-temp exposure, thus improving resistance to intergranular corrosion. In many cases, cast 304/304L is dual-certified, letting you choose the safer option in welded zones.

Q3: Is a cast 304 part magnetic?

In its annealed state, cast 304 is essentially nonmagnetic. But after cold work (machining, bending, etc.) or certain processing, some localized magnetic behavior may occur.

Q4: What heat treatment should be applied to 304 castings?

A solution annealing step (e.g. 1010–1120 °C followed by rapid cooling) is common to dissolve carbides and restore corrosion resistance. Also, normalization and annealing help relieve stress.

Q5: How do I improve corrosion resistance of cast 304 parts?

Use good surface finish, apply passivation (e.g. nitric or citric acid), electropolish, avoid crevices, and maintain clean surfaces. Don’t rely purely on bulk alloy for resisting localized attack.

Q6: When should I opt for 316 or duplex instead of 304?

If your environment includes high chloride levels, seawater, aggressive chemicals, or you have very high corrosion performance expectations, 316 or duplex may give better long-term performance despite higher cost.

Q7: Is acero inoxidable 304 easy to cast?

Yes, it has fair castability and is compatible with common casting methods (investment, sand) for many geometries. Nevertheless, careful gating and riser design are needed, and defects must be controlled.

Manténgase conectado con nosotros

¡Gracias por leer! Esperamos que este blog te haya brindado información valiosa e inspiración sobre techos con paneles acústicos. Si disfrutaste del contenido y quieres estar al día de las últimas tendencias, consejos y novedades, nos encantaría conectar contigo en redes sociales.

📘 Síguenos en Facebook: Shanghai Leierwo Industria Comercio Co., Ltd.

Únase a nuestra creciente comunidad donde compartimos consejos de expertos, aspectos destacados de los productos y debates interactivos con profesionales y entusiastas del diseño de todo el mundo.

Sigamos conversando, ¡nos vemos allí!

Categorías de productos

- Piezas de válvulas

- Piezas de la bomba de agua

- Piezas de la caja de cojinetes

- Piezas de fundición a presión

- Productos para bombas de acero inoxidable

- Productos para bombas de hierro fundido

- Piezas de válvulas para automóviles

- Recambios para automóviles

- Piezas de válvulas para uso civil

- Piezas de bomba de vacío KF