The Complete Guide to 3D Printing for Businesses: Concepts, Applications, and Real-World Insights

3D-Druck, also known as Additive Manufacturing, is transforming industries across the globe. From rapid prototyping to end-use parts, businesses are discovering new ways to increase efficiency, reduce costs, and accelerate innovation. This guide provides a comprehensive overview of 3D Printing concepts, applications, and actionable insights for enterprises considering adoption.

Inhaltsverzeichnis

Was ist 3D-Druck and How Does It Work?

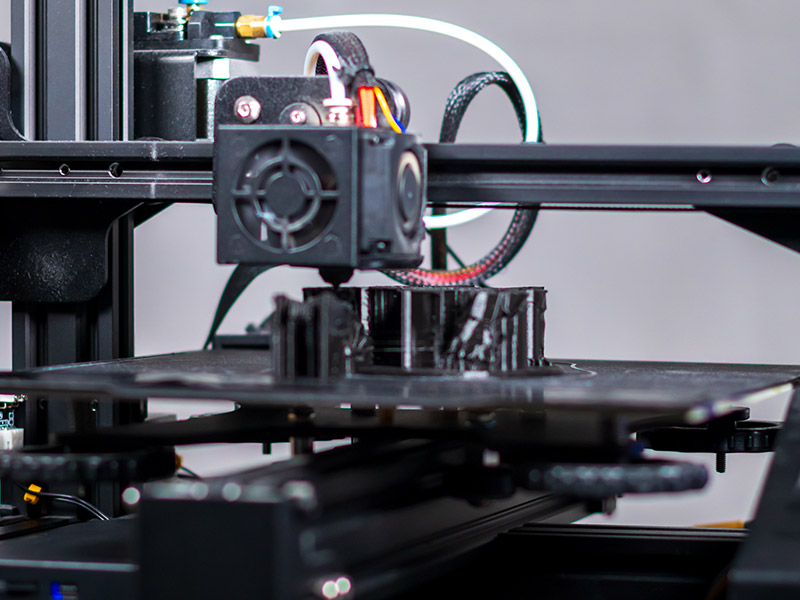

3D Printing is a manufacturing process that builds objects layer by layer from a digital model. Unlike traditional methods that remove material, 3D Printing adds material precisely where it’s needed, reducing waste and increasing design flexibility.

The Concept of Additive Manufacturing

Additive Manufacturing (AM) refers to building objects by adding material incrementally. This approach enables the creation of complex geometries that were previously impossible or very costly to produce.

Basic Workflow in Business Settings

Implementing 3D Printing in a business environment typically follows a structured workflow. Each step has its own considerations, tools, and impact on efficiency and cost. Understanding this workflow helps companies maximize the benefits of additive manufacturing.

Step 1: Digital Design – Creating the 3D Model

The first step in any 3D Printing project is designing the object in CAD (Computer-Aided Design) software. Engineers and designers translate product ideas or functional requirements into a digital 3D model.

- Key Considerations:

- Ensure the design accounts for material properties and printer limitations.

- Integrate functional requirements like strength, flexibility, or assembly constraints.

- Consider design optimization for 3D Printing, such as hollow structures or lattice designs to save material.

Business Insight: Proper upfront design reduces trial-and-error iterations, saving time and materials in later stages.

Beispiel: An aerospace supplier used CAD to redesign a fuel duct with internal channels impossible to create using traditional methods, reducing weight without sacrificing strength.

Step 2: File Preparation – Converting Designs into Printable Formats

Once the 3D model is complete, it must be converted into a format that 3D printers can interpret, usually STL, OBJ, or 3MF. File preparation also includes checking for errors and ensuring the model is watertight (no gaps in the geometry).

- Key Actions:

- Inspect for non-manifold edges or overlapping surfaces that could cause printing failures.

- Adjust scaling, orientation, and supports based on the printer type and material.

- Annotate or include multiple configurations if producing variants.

Business Insight: Proper file preparation minimizes failed prints, reduces wasted material, and ensures higher precision, which is critical for industrial applications.

Step 3: Slicing – Preparing Layers for Printing

Slicing software takes the 3D model and converts it into thin, printable layers, generating a path for the printer to follow.

- Key Considerations:

- Determine layer height: smaller layers increase precision but also printing time.

- Set infill density: balance strength with material consumption.

- Configure support structures for overhangs or complex geometries.

- Optimize print speed and temperature settings according to material specifications.

Business Insight: Smart slicing can significantly impact print quality, speed, and cost efficiency. Experienced teams often create templates for repeated production tasks.

Beispiel: A medical device company optimized slicing settings to print patient-specific surgical models faster while maintaining anatomical accuracy.

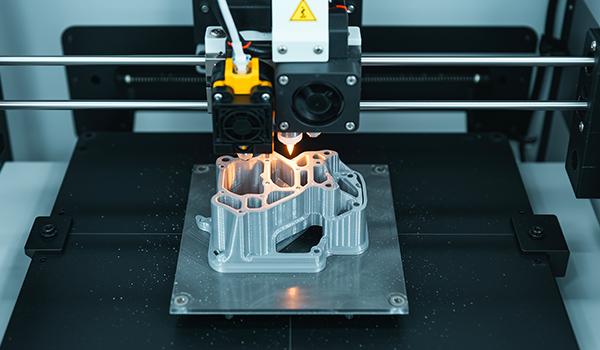

Step 4: Printing and Post-Processing – From Layer to Finished Part

Once the model is sliced, the printer deposits materials layer by layer to create the physical part. After printing, post-processing may include support removal, surface smoothing, curing, or painting, depending on the material and intended use.

- Key Actions:

- Monitor the print to detect errors early.

- Remove supports carefully to avoid damaging delicate features.

- Apply finishing processes like sanding, polishing, or chemical smoothing for aesthetics or mechanical performance.

Business Insight: Post-processing can represent a significant portion of production time and cost, so planning and automation are key for industrial use.

Real-World Example: An automotive supplier used FDM 3D Printing for prototype brackets. By adopting this workflow instead of traditional CNC milling:

- Design iteration cycles decreased from three weeks to three days.

- Material waste was reduced by over 50%.

- Engineers could rapidly test multiple design variations, leading to better overall product performance.

Optional Step 5: Quality Assurance and Testing

In many B2B settings, quality control is integrated into the workflow. Parts may undergo dimensional inspection, mechanical testing, or functional validation before being approved for prototypes or production use.

- Business Insight: Incorporating QA ensures that printed parts meet industry standards, reduces failure risks, and strengthens confidence in additive manufacturing for end-use applications.

Evolution of 3D-Druck in Industry

3D Printing has evolved from a prototyping tool to an integral part of industrial production.

Early Prototyping Era

Initially, 3D Printing helped engineers quickly visualize product designs and test functionality before mass production.

Industrial Adoption

Today, companies integrate industrial-grade printers into production lines for functional components, tooling, and even low-volume end-use parts.

Fallstudie: A leading aerospace company used Selective Laser Sintering (SLS) to produce complex air ducts for aircraft. Traditional fabrication would have required multiple components and joints; 3D Printing reduced assembly steps and improved airflow efficiency.

Core 3D-Druck Technologies and Business Applications

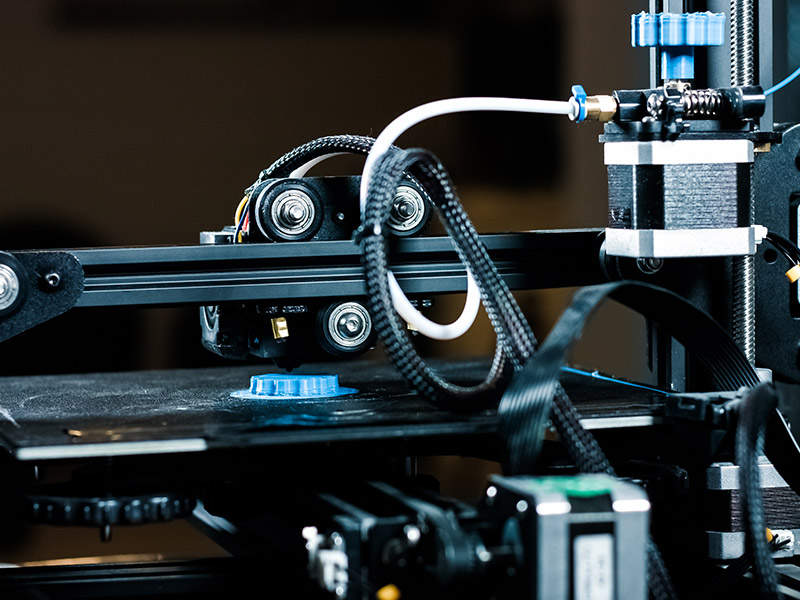

Fused Deposition Modeling (FDM)

FDM melts plastic filament and deposits it layer by layer. It is affordable and widely used for prototyping and small-batch functional parts.

Stereolithography (SLA)

SLA uses UV light to cure resin, creating high-precision parts. This is common in dental, medical, and design applications.

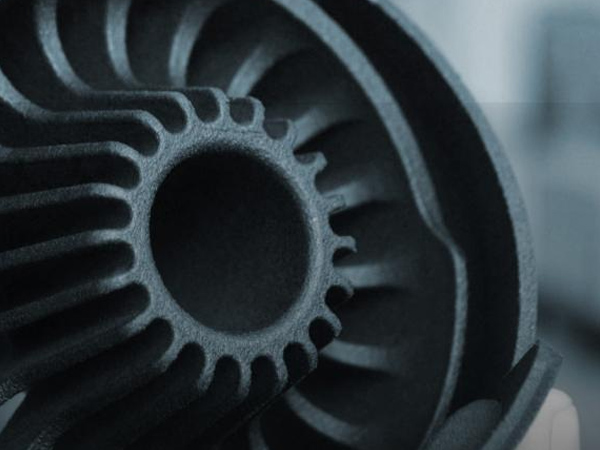

Selective Laser Sintering (SLS)

SLS fuses powdered materials with lasers, producing durable, functional parts without supports.

Comparison of Key Technologies

| Technologie | Material | Präzision | Speed | Ideal Use |

|---|---|---|---|---|

| FDM | Thermoplastics | Medium | Hoch | Prototyping, tooling |

| SLA | Resin | Hoch | Medium | Aesthetic, detailed parts |

| SLS | Powder (plastic/metal) | Hoch | Medium-Low | Functional end-use parts, complex geometries |

Interpretation: Businesses should choose a technology based on the part’s purpose, desired precision, and material requirements. FDM is cost-effective for prototypes, SLA excels in detailed models, and SLS is best for durable functional parts.

Materials for Business 3D-Druck

Thermoplastics

Materials like PLA, ABS, and PETG are versatile, lightweight, and suitable for prototypes or production aids.

Metal Powders

Industrial applications in aerospace and automotive rely on metals such as aluminum, titanium, or stainless steel for strength and heat resistance.

Harze

High-resolution resins are ideal for dental, medical, and jewelry applications, where precision and surface finish are critical.

Emerging Composites

Carbon-fiber reinforced plastics and bio-compatible materials are increasingly used to achieve high performance with sustainability in mind.

Fallstudie: A medical device company adopted SLA resin printing to produce patient-specific surgical guides. The guides reduced surgery time and improved patient outcomes while lowering production costs.

3D-Druck Anwendungen Branchenübergreifend

3D Printing is no longer limited to prototyping—it has become an integral tool for businesses across multiple sectors. From cost savings to design freedom, the technology provides measurable benefits that impact efficiency, innovation, and product performance.

Herstellung

In modern manufacturing, 3D Printing is transforming how products are designed and produced. Companies can rapidly create prototypes, develop custom tooling, and even produce low-volume functional parts without the need for expensive molds or setups.

Key Benefits:

- Rapid Prototyping: Engineers can test multiple design iterations in days rather than weeks.

- Custom Tooling: Jigs, fixtures, and molds can be 3D printed, reducing setup times for production lines.

- Low-Volume Production: Small batches of functional parts can be produced economically, eliminating the minimum order constraints of traditional methods.

Fallstudie: A consumer electronics manufacturer used FDM 3D Printing to produce custom assembly fixtures. The result: a 50% reduction in setup time and faster launch of a new product line.

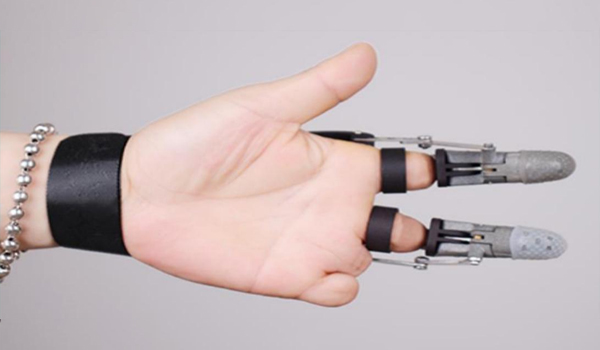

Healthcare

3D Printing has enabled personalized medicine, allowing healthcare providers to tailor implants, prosthetics, and surgical tools to individual patients.

Key Benefits:

- Custom Implants and Prosthetics: Each piece is designed based on patient scans, improving fit and comfort.

- Surgical Planning Models: Surgeons can rehearse procedures on 3D printed anatomical models, reducing operation times and improving precision.

- Rapid Production: Urgent medical devices can be printed on-demand, bypassing long supply chains.

Fallstudie: A hospital in Germany used SLA printing to produce patient-specific dental implants. Printing each implant in-house reduced lead time from four weeks to two days, improving patient satisfaction and surgical outcomes.

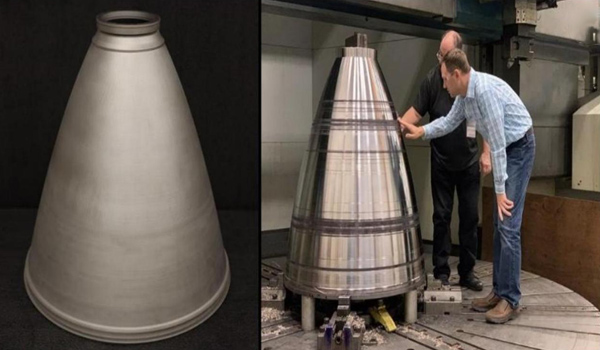

Luft- und Raumfahrt

In aerospace, 3D Printing is used for creating lightweight, high-strength components, which helps reduce fuel consumption and assembly complexity.

Key Benefits:

- Weight Reduction: Complex parts can be designed with lattice structures to reduce weight without compromising strength.

- Complex Geometries: Parts that would require multiple assemblies in traditional manufacturing can be printed as a single piece.

- Material Efficiency: Less material waste compared to subtractive methods like CNC milling.

Fallstudie: A European aircraft manufacturer replaced a traditional multi-part duct assembly with a single 3D printed titanium component. This reduced part weight by 15% and assembly time by 30%, improving overall aircraft performance.

Konstruktion

3D Printing in construction is gaining traction with large-scale concrete and composite structures. It allows for innovative architectural designs while reducing labor and material costs.

Key Benefits:

- Design Freedom: Curved walls, intricate facades, and complex structures can be printed without molds.

- Material Savings: Only the necessary concrete or composite material is used, minimizing waste.

- Faster Build Times: Large sections of buildings can be printed in days instead of weeks.

Fallstudie: A construction company in the Netherlands used 3D Printing to build a prototype house in just 120 hours, using 60% less concrete than conventional construction while maintaining structural integrity.

Automobilindustrie

Automotive companies leverage 3D Printing for prototyping, producing functional components, and testing new designs.

Key Benefits:

- Custom Parts: Limited edition or replacement parts can be produced without mass production runs.

- Rapid Prototyping: Engineers test multiple iterations of dashboards, brackets, or housings quickly.

- Functional Testing: Components can be printed in the final material for real-world testing before committing to large-scale production.

Fallstudie: A global car manufacturer used SLS 3D Printing to produce lightweight engine covers for prototype vehicles. This enabled faster testing of multiple designs and reduced overall development time by 40%.

Parameterized Comparison: 3D-Druck vs Traditional Manufacturing

| Aspekt | Traditionelle Fertigung | 3D Printing (Additive Manufacturing) |

|---|---|---|

| Materialabfall | Hoch | Minimal |

| Designflexibilität | Beschränkt | High (complex geometries possible) |

| Setup Cost | Expensive tooling | Low (digital design, no molds) |

| Produktionsgeschwindigkeit | Fast for mass production | Faster for prototypes & small batches |

| Cost for Custom Parts | Sehr hoch | Moderate/Low |

| Wartung | Standard | Requires trained staff & calibration |

Insight: Many B2B companies adopt a hybrid approach, using traditional manufacturing for large volumes and 3D Printing for prototypes, custom parts, or low-volume production.

Business Value: Why Companies Invest in 3D-Druck

Faster Time-to-Market

Rapid prototyping enables companies to iterate designs and launch products more quickly.

Reduced Production Costs

Eliminating molds and reducing material waste lowers both initial and recurring costs.

Customization and Agility

3D Printing allows businesses to offer small-batch, customized solutions without retooling their production lines.

Sustainability Benefits

Precise material usage reduces waste, contributing to environmentally friendly manufacturing processes.

Real-World Example: A consumer electronics company used 3D Printing for small-batch enclosures, reducing material usage by 40% compared to injection molding.

Implementing 3D-Druck in Your Enterprise

Step 1: Define Goals

Determine whether your primary objective is prototyping, production, or supply chain optimization.

Step 2: Evaluate Technology and Materials

Select the appropriate printing method based on material compatibility, part precision, and business requirements.

Step 3: Decide on In-House vs Outsourcing

Industrial printers are a significant investment. Consider outsourcing to a professional 3D Printing service bureau if usage is sporadic.

Step 4: Train Teams and Establish Workflows

Ensure engineers and designers understand the software, printer operation, and post-processing procedures for consistent quality.

Future Trends in Industrial 3D-Druck

AI-Assisted Design

Artificial intelligence and generative design tools optimize geometries for strength, weight, and material efficiency.

Sustainable Materials

New recyclable plastics and composites support green manufacturing goals.

Distributed Manufacturing

Producing components closer to demand reduces shipping costs and enhances supply chain resilience.

Häufig gestellte Fragen

What industries benefit most from 3D-Druck today?

Manufacturing, aerospace, healthcare, automotive, and construction industries benefit from faster prototyping, cost reduction, and design flexibility.

Ist 3D-Druck worth it for small businesses?

Yes, particularly for prototyping, short runs, or customized products. Outsourcing options also make it accessible without heavy upfront investment.

How strong are 3D printed parts compared to traditional manufacturing?

Depending on the material and technology, parts can match or exceed traditional materials’ mechanical properties.

Should my company buy a 3D printer or use a service provider?

Frequent printing favors in-house ownership; occasional needs are more cost-effective via service providers.

What are the main limitations?

Speed, material availability, and part size are key constraints, but technology is rapidly advancing.

Ready to Take the Next Step?

3D Printing can revolutionize your business operations, from reducing costs to accelerating innovation. If you want custom advice on integrating 3D Printing into your workflow, contact our engineers today. Our team can provide technology recommendations, ROI analysis, and real-world implementation strategies tailored to your industry.

Bleiben Sie mit uns in Verbindung

Vielen Dank fürs Lesen! Wir hoffen, dieser Blogbeitrag hat Ihnen wertvolle Einblicke und Inspirationen zum Thema Akustikdecken gegeben. Wenn Ihnen der Inhalt gefallen hat und Sie über die neuesten Trends, Tipps und Einblicke hinter die Kulissen auf dem Laufenden bleiben möchten, würden wir uns freuen, mit Ihnen über die sozialen Medien in Kontakt zu treten.

📘 Folgen Sie uns auf Facebook: Shanghai Leierwo Industriehandel Co., Ltd.

Treten Sie unserer wachsenden Community bei, in der wir Expertenratschläge, Produkthighlights und interaktive Diskussionen mit Fachleuten und Design-Enthusiasten aus der ganzen Welt teilen.

Lassen Sie uns das Gespräch fortsetzen – wir sehen uns dort!

Produktkategorien

- Ventilteile

- Wasserpumpenteile

- Lagergehäuseteile

- Druckgussteile

- Pumpenprodukte aus Edelstahl

- Pumpenprodukte aus Gusseisen

- Ventilteile für den Automobilgebrauch

- Autoteile

- Ventilteile für den zivilen Gebrauch

- Vakuumpumpenteile KF