Impellerpumpe vs. Kreiselpumpe: Welche ist besser?

Willkommen auf meinem Blog!

Ich freue mich sehr, dass du hier bist! Bevor wir uns in die Inhalte vertiefen, würde ich mich freuen, wenn du mir auf meinen Social-Media-Plattformen folgst. Dort teile ich zusätzliche Einblicke, vernetze mich mit unserer großartigen Community und halte dich über die neuesten Nachrichten auf dem Laufenden. So bleibst du in Verbindung:

📘 Facebook: Shanghai Leierwo Industriehandel Co., Ltd.

Lassen Sie uns gemeinsam auf diese Reise gehen! Ich hoffe, Sie finden die Inhalte hier nicht nur aufschlussreich, sondern auch inspirierend und wertvoll. Los geht‘s!

Inhaltsverzeichnis

Einführung

Pumps are essential in many industries, from water treatment plants to manufacturing processes. They help transfer liquids and gases with ease, improving efficiency and productivity. Two popular types of pumps are the Impellerpumpe and the centrifugal pump. Both play vital roles in fluid handling, but how do they compare? In this article, we’ll explore the mechanisms behind both pumps, the pros and cons of each, and provide guidance on which one might be better for your specific requirements.

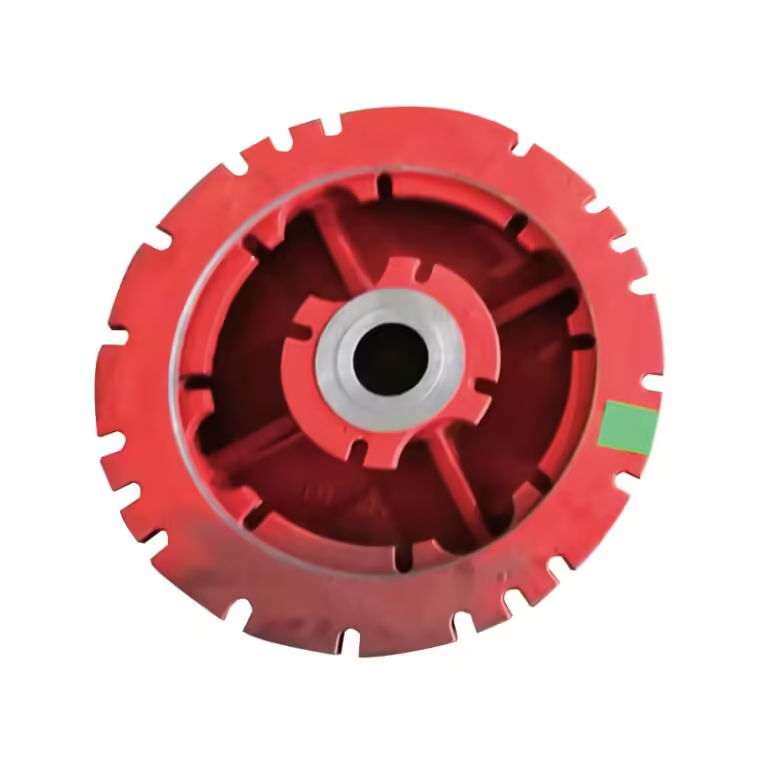

What Is an Impeller Pump?

An impeller pump is a type of dynamic pump that uses the energy imparted to the liquid by an impeller to move the fluid through the system. The impeller, which is a rotating component, transfers energy to the fluid, causing it to flow and create pressure within the pump. This action enables the liquid to be moved through piping systems, making impeller pumps an essential tool for fluid management in various industries.

Impeller pumps are commonly used in industries requiring high flow rates and applications where the fluid needs to be moved quickly or over long distances. These pumps are employed in many sectors, including agriculture, water treatment, HVAC (heating, ventilation, and air conditioning) systems, and more. Their ability to handle large quantities of liquid makes them versatile and indispensable in processes where efficient fluid transfer is needed.

Key Features of Impeller Pumps:

- High flow rates: One of the key advantages of impeller pumps is their ability to handle high flow rates. This makes them ideal for applications that require large volumes of fluid to be moved quickly, such as water treatment, sewage management, and industrial cooling systems.

- Variable flow: Another important feature of impeller pumps is their ability to handle variable flow rates. By adjusting the speed of the impeller or modifying the system’s settings, the performance of the pump can be altered, making it adaptable to different process requirements.

- Vielseitigkeit: Impeller pumps are known for their versatility in handling a wide variety of fluids. Whether the liquid is clear, like water, or more viscous, such as oils or slurries, impeller pumps can be used across various industries. They can accommodate diverse operating conditions, making them a flexible option for many applications.

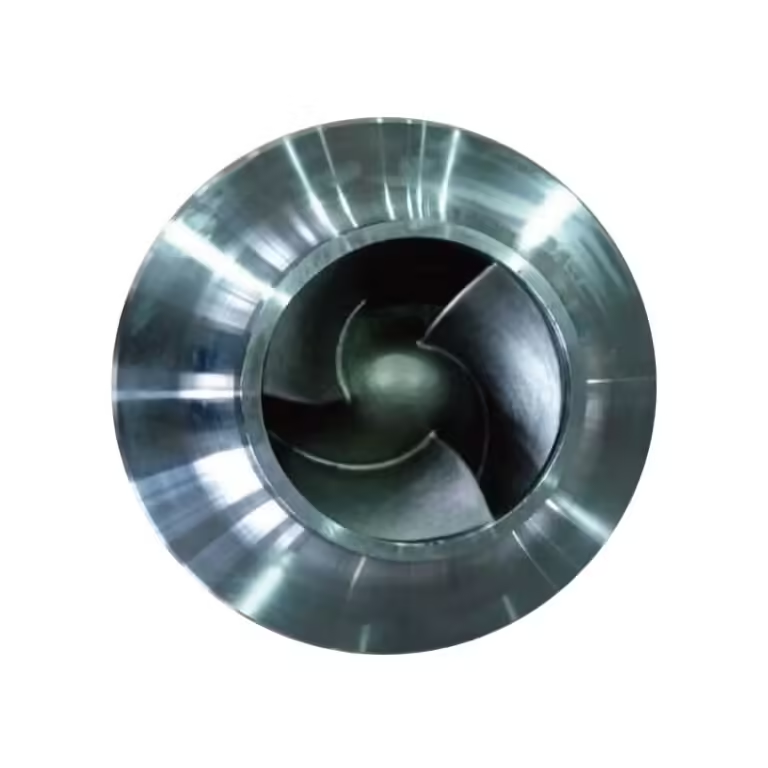

What Is a Centrifugal Pump?

A centrifugal pump is another widely used type of pump that operates on the principle of centrifugal force. It uses a rotating impeller to impart velocity to the fluid, converting this velocity into flow. The centrifugal force generated by the impeller causes the fluid to move outward from the center of the pump casing, creating a pressure differential that moves the liquid through the system.

Centrifugal pumps are one of the most common types of pumps found in industrial and commercial settings. They are primarily used in applications where fluids need to be transferred over short or medium distances at a consistent flow rate. These pumps are commonly found in industries such as chemical processing, oil and gas, HVAC, and water treatment.

Key Features of Centrifugal Pumps:

- Simplicity: Centrifugal pumps have fewer moving parts compared to other types of pumps. This simplicity makes them easy to operate and maintain, which reduces downtime and operational costs. The relatively straightforward design also contributes to the pump’s reliability.

- Wide range of applications: These pumps are highly versatile and can be used in various industries. Centrifugal pumps are ideal for transferring clean water, chemicals, oils, and even slurries in some cases. Their robust design allows them to function across a broad spectrum of industrial processes.

- Energy-efficient: Centrifugal pumps are known for their energy efficiency, particularly when used in applications with steady, consistent flow rates. This efficiency is crucial in reducing operational costs and enhancing system performance, especially in large-scale applications.

Impeller Pump vs. Centrifugal Pump: Key Differences

Now that we’ve discussed the fundamentals of both impeller and centrifugal pumps, it’s essential to dive deeper into the key differences between these two types. Although both pumps use a rotating impeller to move fluids, their mechanisms and applications differ. Let’s compare them based on various factors.、

Mechanism of Action

- Impeller Pump: The rotating impeller in an impeller pump creates energy that is transferred to the fluid, converting mechanical energy into kinetic energy. As the impeller spins, it pushes the liquid through the pump system, increasing its flow rate and pressure. This results in efficient fluid transport, especially over long distances or at high pressures.

- Centrifugal Pump: In contrast, a centrifugal pump relies on centrifugal force to move the fluid. The rotating impeller accelerates the fluid outward, creating a pressure differential that drives the fluid through the system. The force generated by the impeller is proportional to the fluid’s velocity and the pump’s rotational speed.

Application Suitability

- Impeller Pump: Impeller pumps are ideal for high-flow, high-pressure applications. They are commonly used in applications where large volumes of fluid need to be moved over extended distances, such as water treatment, irrigation, and agricultural systems. Impeller pumps excel in applications requiring versatility and adaptability to varying fluid types.

- Centrifugal Pump: Centrifugal pumps are better suited for low to medium flow rate applications. These pumps are typically used for processes that require a steady, reliable flow of liquid, such as chemical processing, HVAC systems, and clean water pumping. They are also used in industrial settings where space and efficiency are key factors.

Efficiency and Power Consumption

- Impeller Pump: Impeller pumps are typically less energy-efficient than centrifugal pumps, especially when handling fluctuating or irregular fluid flow. The efficiency of impeller pumps can decrease when the flow is not consistent, making them less ideal for applications where precise control of flow rates is necessary. However, they are highly effective in situations requiring large amounts of fluid to be moved quickly.

- Centrifugal Pump: Centrifugal pumps are generally more energy-efficient, especially in applications where flow rates are consistent. These pumps operate best when maintaining steady flow and pressure. They are often the go-to choice for large-scale applications that require low energy consumption over extended periods.

- Performance Under Varying Conditions

Performance Under Varying Conditions

- Impeller Pump: Impeller pumps perform well under a broad range of fluid conditions. They are capable of handling both low- and high-viscosity liquids, making them a versatile option for industries that work with varied fluid properties. Whether it’s water, oils, or other thicker liquids, impeller pumps can be adjusted to handle the specific needs of the system.

- Centrifugal Pump: Centrifugal pumps can face challenges when dealing with high-viscosity fluids or liquids containing solids. These conditions can lead to a decrease in efficiency and potential wear on the pump components. However, centrifugal pumps are highly efficient for clean fluids, such as water or chemicals without large particulates.

Comparison Table: Impeller Pump vs. Centrifugal Pump

| Besonderheit | Impeller Pump | Centrifugal Pump |

|---|---|---|

| Mechanism | Rotating impeller transfers energy to fluid | Rotating impeller creates centrifugal force to move fluid |

| Flow Rate | High flow, variable performance | Moderate flow, stable performance |

| Energieeffizienz | Less energy-efficient for variable flows | More energy-efficient, especially in steady-flow applications |

| Anwendung | Water treatment, agriculture, HVAC | Chemical processing, irrigation, clean water |

| Fluid Handling | Versatile with various fluid types | Best for clean or low-viscosity fluids |

| Kosten | Typically higher due to complexity | More affordable and simple to maintain |

| Wartung | Requires regular servicing and maintenance | Low maintenance, simple design |

Which Pump Is Better for Your Needs?

Choosing between an impeller pump and a centrifugal pump depends largely on the specific needs of your application. Here’s a quick guide to help you decide:

- Choose an Impeller Pump if:

- You require high flow rates and higher pressure.

- You’re handling viscous liquids or varying fluid types.

- You need a pump for agricultural, water treatment, or HVAC applications.

- Choose a Centrifugal Pump if:

- You need a cost-effective, simple-to-operate pump.

- You are dealing with clean water or low-viscosity fluids.

- You want a pump that offers energy efficiency for consistent-flow applications.

Advantages and Disadvantages of Each Pump

Advantages of Impeller Pumps:

- High flow rates and pressure.

- Versatile, suitable for a wide range of fluid types.

- Can handle varying operating conditions.

Disadvantages of Impeller Pumps:

- Less energy-efficient, especially with varying flow rates.

- Typically more complex and costly.

- Requires more maintenance and regular servicing.

Advantages of Centrifugal Pumps:

- Energy-efficient, particularly in steady-flow applications.

- Simpler and more affordable to operate.

- Low maintenance and durable.

Disadvantages of Centrifugal Pumps:

- Less effective with high-viscosity liquids or liquids containing solids.

- Not ideal for high-flow, high-pressure requirements.

Abschluss

Both impeller pumps and centrifugal pumps have their unique advantages and limitations. The key to making the right choice lies in understanding the requirements of your application, including flow rates, pressure levels, fluid types, and efficiency needs. Impeller pumps are ideal for high-flow, high-pressure tasks, while centrifugal pumps excel in steady-flow, low-viscosity applications. By carefully considering these factors, you can choose the pump that best meets your needs and ensures optimal performance.

Häufig gestellte Fragen

What is the main difference between an Impellerpumpe and a centrifugal pump?

The main difference is the way each pump generates pressure. An impeller pump uses the energy imparted by a rotating impeller to move the fluid, while a centrifugal pump relies on centrifugal force to create flow.

Which pump is more efficient for handling high-viscosity fluids?

Impeller pumps are more efficient for handling high-viscosity fluids, as they can manage a variety of fluid types and conditions.

Are centrifugal pumps better for steady-flow applications?

Yes, centrifugal pumps are more energy-efficient and reliable for steady-flow applications, making them ideal for chemical processing and clean water systems.

Kann impeller pumps be used for low-flow applications?

While impeller pumps are optimized for high-flow applications, they can be used in low-flow situations, though their efficiency may be reduced.

Produktkategorien

- Ventilteile

- Wasserpumpenteile

- Lagergehäuseteile

- Druckgussteile

- Pumpenprodukte aus Edelstahl

- Pumpenprodukte aus Gusseisen

- Ventilteile für den Automobilgebrauch

- Autoteile

- Ventilteile für den zivilen Gebrauch

- Vakuumpumpenteile KF