Coupler Manufacturing Guide: Materials, Types, and Industrial Applications

Couplers are essential components in mechanical systems, connecting power sources to driven equipment while ensuring efficient torque transmission, reducing vibrations, and preventing equipment failure. Understanding coupler manufacturing, materials, design considerations, and testing methods is crucial for engineers, procurement professionals, and maintenance teams.

Inhaltsverzeichnis

Verständnis Kupplungsherstellung

Coupler manufacturing is a highly specialized process that ensures optimal torque transmission, mechanical reliability, and long-term durability. It encompasses several critical stages, including material selection, precision machining, heat treatment, surface finishing, and quality inspection. Each step directly influences the coupler’s performance under operational loads, environmental conditions, and repetitive stress cycles.

The success of a coupler in industrial applications depends not only on the raw materials but also on strict adherence to manufacturing tolerances. Small deviations in dimensions, surface roughness, or balance can significantly impact torque efficiency, introduce vibrations, and reduce the lifespan of the connected machinery. Therefore, process control and precision engineering are cornerstones of modern coupler manufacturing.

What is a Coupler?

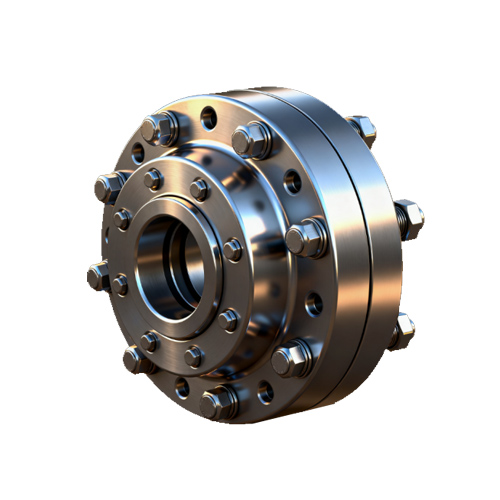

A coupler is a mechanical device designed to connect two rotating shafts or components, enabling the transfer of torque and rotational motion from a driving element to a driven element. Couplers often accommodate minor misalignments, absorb shocks, and reduce vibrations within the system.

By maintaining proper alignment between shafts, couplers help prevent excessive wear on bearings, reduce noise, and enhance the operational stability of machines. They are widely used in industrial machinery, pumps, motors, generators, conveyor systems, and high-speed equipment.

Couplers can also serve as safety components, protecting equipment from overloads. For example, certain flexible couplers are designed to slip or deform slightly under excessive torque, preventing catastrophic failures in downstream components.

Key Manufacturing Principles

Producing high-quality couplers requires a combination of precision engineering, material science, and rigorous process control. The core principles include:

- Tight Dimensional Tolerances: Maintaining precise shaft diameters, hub lengths, and bore alignments ensures consistent torque transfer and reduces vibration.

- Controlled Heat Treatment: Enhances mechanical properties such as hardness, tensile strength, and fatigue resistance. Heat treatment also improves wear resistance and prevents deformation under high stress.

- Surface Finishing: Smooth, balanced surfaces reduce friction, prevent stress concentrations, and extend service life. Coatings or plating can also improve corrosion resistance.

- Quality Inspection: Each coupler is tested for torque capacity, misalignment tolerance, and dimensional accuracy to meet industrial standards and customer specifications.

Even minor deviations in any of these areas can lead to premature failure, reduced operational efficiency, or increased maintenance requirements.

Types of Couplers and Their Applications

Couplers are engineered to match the operational requirements of the machinery, balancing torque transmission, flexibility, and vibration damping. Choosing the right type depends on load capacity, shaft alignment, rotational speed, and environmental conditions.

Rigid Couplers

Rigid couplers create a solid, inflexible connection between shafts, providing maximum torque transfer efficiency. They are commonly used in applications where shaft alignment is precise and misalignment is negligible.

- Vorteile: Maximum torque transfer, simple construction, low maintenance.

- Limitations: Cannot compensate for misalignment, unsuitable for dynamic or vibrating systems.

- Typical Applications: CNC machines, precision lathes, and low-speed mechanical equipment.

Real-World Example:

In a German manufacturing plant producing precision gearboxes, rigid couplers were used to connect the motor shaft to a high-precision spindle. Their precise construction ensured minimal backlash and highly accurate torque transmission, which was critical for machining tolerances under 0.01 mm.

Flexible Couplers

Flexible couplers are designed to absorb misalignment and reduce vibrations, protecting connected machinery from stress. They can accommodate angular, axial, or parallel offset, making them versatile in industrial environments.

- Vorteile: Misalignment compensation, vibration damping, protection against overload.

- Limitations: Slightly lower maximum torque capacity compared to rigid couplers.

- Typical Applications: Pumps, compressors, conveyors, and industrial machinery.

Parameter Insight:

Flexible couplers are often rated by maximum angular misalignment (1–3°), axial displacement (0.5–2 mm), and torque rating. Correctly matching these parameters to the equipment prevents early failure and maintains operational efficiency.

Disc or Membrane Couplers

Disc or membrane couplers are high-performance flexible couplers suitable for high-speed applications. They use thin metallic discs that flex under misalignment while maintaining precise torque transmission.

- Vorteile: High-speed capability, vibration damping, excellent fatigue life.

- Limitations: Requires precise installation; less forgiving of extreme misalignment.

- Typical Applications: High-speed motors, turbines, and precision industrial equipment.

Fallstudie:

A power generation facility in Singapore used disc couplers to connect turbine shafts to generators operating at 3000 RPM. The couplers compensated for thermal expansion and minor misalignments, significantly reducing maintenance downtime and extending operational life.

Comparative Performance Table

| Coupler Type | Max Torque (Nm) | Misalignment Compensation | Operating Speed (RPM) | Typical Applications |

|---|---|---|---|---|

| Rigid Coupler | 1200 | None | 1000–3000 | Precision machinery |

| Flexible Coupler | 900 | Angular 2°, Axial 1 mm | 800–2500 | Pumps, conveyors, motors |

| Disc Coupler | 1000 | Angular 1°, Axial 0.5 mm | 2000–5000 | High-speed machinery |

This table helps engineers compare coupler types for torque capacity, speed range, and misalignment tolerance, enabling better material and type selection for specific industrial applications.

Materials and Manufacturing Processes

Der materials and manufacturing processes in coupler manufacturing play a critical role in determining mechanical performance, durability, and service life. Proper coupler manufacturing ensures the final product can withstand operational stresses, misalignments, and harsh environmental conditions. Choosing the right material and following precise fabrication techniques is essential for high-quality coupler manufacturing outcomes.

Common Materials of Kupplungsherstellung

Couplers are typically produced using steel alloys, aluminum, stainless steel, or composite materials, with the material choice directly impacting performance and application suitability.

Steel Alloys

Provide high strength, toughness, and wear resistance, making them ideal for heavy-duty coupler manufacturing and high-torque industrial applications.

Aluminium

Offers lightweight properties, ideal for high-speed machinery where reducing rotational inertia is critical.

Edelstahl

Exzellent Korrosionsbeständigkeit and moderate strength, perfect for marine, chemical, or high-humidity environments.

Composite Materials

Provide vibration damping, lightweight performance, and corrosion resistance, commonly used in advanced coupler manufacturing for noise-sensitive or fatigue-prone applications.

Selecting the proper material depends on torque requirements, operational speed, environmental conditions, and maintenance capabilities. For example, high-torque pump systems in chemical plants often prefer stainless steel for its combination of strength and corrosion resistance.

Manufacturing Techniques in Kupplungsherstellung

The manufacturing process of couplers involves several key techniques, each contributing to final performance:

Casting and Forging

Create the initial coupler shape with a controlled grain structure, ensuring mechanical strength and durability under dynamic loads, which is fundamental in industrial coupler manufacturing.

CNC-Bearbeitung

Enables precise bore diameters, hub dimensions, and overall balance, reducing vibration and ensuring accurate torque transmission.

Wärmebehandlung

Improves hardness, fatigue resistance, and toughness, ensuring the coupler can handle repeated torque cycles without deformation or cracking.

Oberflächenbehandlung

Techniques like coating, plating, or nitriding enhance wear resistance, reduce friction, and protect against corrosion. Proper surface treatment is particularly critical for flexible couplers in humid or chemical environments.

Real-World Example:

In a textile machinery plant in Germany, flexible steel couplers were CNC machined and heat-treated to withstand continuous operation for over 8 years without failure. Their precise machining ensured smooth torque transmission between motors and gearboxes, preventing misalignment issues common in high-speed production lines.

Design and Engineering Considerations in Kupplungsherstellung

Torque and Load Requirements

Selecting the correct coupler begins with analyzing maximum operating torque, load fluctuations, and torque peaks. Couplers produced via precise coupler manufacturing must handle peak torque without permanent deformation to protect connected motors, gearboxes, and other equipment.

For instance, a cement plant in India utilized high-strength steel couplers manufactured under stringent coupler manufacturing standards, rated for up to 1200 Nm of torque, allowing machinery to operate continuously under dynamic loads without interruption.

Misalignment and Vibration Control

Misalignment is common in industrial systems. Flexible couplers designed through advanced coupler manufacturing processes absorb axial, angular, and parallel misalignments, minimizing stress on bearings and reducing operational noise.

Vibration control is also critical. Improper alignment can cause premature wear and reduce equipment lifespan. Couplers manufactured with vibration damping features in modern coupler manufacturing are ideal for conveyors, compressors, and industrial mixers.

Environmental Conditions

Coupler performance is strongly influenced by the operating environment:

- Temperature: High-speed or heavy-duty machinery generates heat, requiring materials that maintain mechanical properties under thermal stress.

- Humidity and Corrosion: Stainless steel or coated steel couplers are essential in marine, chemical, or outdoor industrial applications.

- Chemical Exposure: In chemical plants, couplers may face acidic or caustic environments, necessitating corrosion-resistant materials and surface coatings.

Testing and Quality Assurance

CCouplers undergo rigorous testing to ensure they meet mechanical and operational standards.

- Torsional Strength Tests: Verify the coupler can transmit its rated torque without permanent deformation.

- Fatigue Testing: Simulates long-term cyclical loading to identify potential failure points.

- Angular Misalignment Tests: Ensure torque transmission efficiency remains consistent even under slight misalignments.

Quality Standards:

Manufacturers follow ISO 9001, DIN, AGMA, and other regional certifications to ensure consistent performance. Documentation such as mill test reports (MTRs) and inspection certificates provides transparency and confidence to engineers and procurement teams.

Fallstudie:

A chemical processing plant in Singapore installed stainless steel couplers for pump systems. Routine inspections and scheduled lubrication allowed the couplers to operate reliably for over seven years. The proactive maintenance program prevented costly downtime and extended system life, demonstrating how material selection and quality assurance complement each other in industrial applications.AGMA, and other regional certifications to guarantee consistent quality and performance across batches. Mill test reports and inspection certificates provide transparency and confidence to end users.

Maintenance and Longevity

Proper maintenance is critical to maximize coupler lifespan and system reliability.

- Regular Inspections: Monitoring wear, cracks, and misalignment helps prevent failures before they occur.

- Lubrication: Flexible couplers may require periodic lubrication to reduce friction and wear.

- Replacement Scheduling: Using operational hours and vibration monitoring to plan replacement avoids unexpected downtime.

Beispiel: In a food processing facility in Australia, a flexible coupler in a high-speed conveyor was inspected quarterly. Early detection of minor wear allowed timely replacement, avoiding a potential production stoppage and maintaining strict hygiene standards.

Market Trends and Industry Insights

The global demand for high-quality couplers is increasing, driven by industrial automation, renewable energy projects, and expanding infrastructure.

Regional Demand

- North America and Europe: Focus on precision couplers for automation, robotics, and high-speed manufacturing.

- Asia-Pacific: Rapid industrial growth drives demand for flexible and durable couplers in mining, construction, and manufacturing sectors.

- Middle East and Africa: Import high-performance couplers that comply with international standards, often used in oil & gas, power, and infrastructure projects.

Pricing Considerations

Coupler prices are influenced by material choice, manufacturing complexity, and supply-demand dynamics. Steel alloy couplers may cost more upfront than aluminum or composite versions but often offer longer service life and reduced maintenance costs. Monitoring global material markets and regional supply chains allows procurement teams to optimize budgets and secure reliable delivery schedules.

Häufig gestellte Fragen

How long do industrial couplers typically last?

Coupler lifespan depends on material, type, and operational conditions, usually ranging 5–15 years bei richtiger Wartung.

Should I choose rigid or flexible couplers?

Rigid couplers are ideal for high-torque, fixed alignment applications. Flexible couplers are better for misalignment, vibration absorption, or thermal expansion.

Can couplers be customized for specific machinery?

Yes. Couplers can be engineered for specific torque ratings, speed, misalignment tolerance, and materials, based on project requirements.

What defects are common in coupler manufacturing?

Dimensional inaccuracies, cracks from improper heat treatment, and surface imperfections are common defects affecting performance.

Abschluss

Coupler manufacturing is a critical factor for mechanical system efficiency, reliability, and safety. Understanding coupler types, materials, design considerations, testing standards, and market trends allows engineers and procurement teams to make informed decisions for industrial applications.

Need customized coupler solutions or casting services? Contact our engineers today to discuss your project requirements and receive expert guidance.

Bleiben Sie mit uns in Verbindung

Vielen Dank fürs Lesen! Wir hoffen, dieser Blogbeitrag hat Ihnen wertvolle Einblicke und Inspirationen zum Thema Akustikdecken gegeben. Wenn Ihnen der Inhalt gefallen hat und Sie über die neuesten Trends, Tipps und Einblicke hinter die Kulissen auf dem Laufenden bleiben möchten, würden wir uns freuen, mit Ihnen über die sozialen Medien in Kontakt zu treten.

📘 Folgen Sie uns auf Facebook: Shanghai Leierwo Industriehandel Co., Ltd.

Treten Sie unserer wachsenden Community bei, in der wir Expertenratschläge, Produkthighlights und interaktive Diskussionen mit Fachleuten und Design-Enthusiasten aus der ganzen Welt teilen.

Lassen Sie uns das Gespräch fortsetzen – wir sehen uns dort!

Produktkategorien

- Ventilteile

- Wasserpumpenteile

- Lagergehäuseteile

- Druckgussteile

- Pumpenprodukte aus Edelstahl

- Pumpenprodukte aus Gusseisen

- Ventilteile für den Automobilgebrauch

- Autoteile

- Ventilteile für den zivilen Gebrauch

- Vakuumpumpenteile KF