Cast Iron Check Valve vs Stainless Steel: Which One Should You Choose?

Willkommen auf meinem Blog!

Ich freue mich sehr, dass du hier bist! Bevor wir uns in die Inhalte vertiefen, würde ich mich freuen, wenn du mir auf meinen Social-Media-Plattformen folgst. Dort teile ich zusätzliche Einblicke, vernetze mich mit unserer großartigen Community und halte dich über die neuesten Nachrichten auf dem Laufenden. So bleibst du in Verbindung:

📘 Facebook: Shanghai Leierwo Industriehandel Co., Ltd.

Lassen Sie uns gemeinsam auf diese Reise gehen! Ich hoffe, Sie finden die Inhalte hier nicht nur aufschlussreich, sondern auch inspirierend und wertvoll. Los geht‘s!

Inhaltsverzeichnis

Blog Key Takeaways

- Comprehensive comparison between cast iron and stainless steel check valves

- Material properties, durability, and performance metrics

- Typical applications and industry-specific recommendations

- Maintenance, installation tips, and cost considerations

- Expert insights and real-world case studies

- Comparative table for quick reference

- Expanded FAQ for common engineering and procurement questions

Einführung

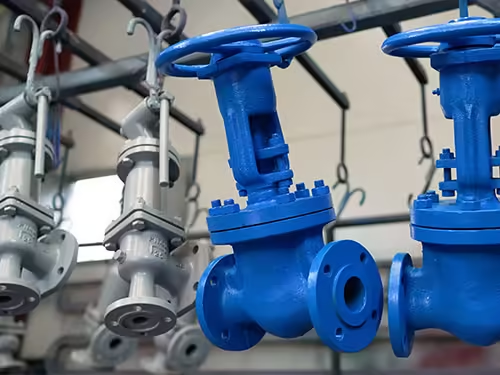

Selecting the right material for a check valve is more than just a technical decision—it can determine the efficiency, reliability, and longevity of your piping system. Cast iron check valves and stainless steel check valves are two of the most popular options in industrial, municipal, and commercial applications. Both materials are castable, making them versatile for a variety of sizes and specifications.

According to the Valve Manufacturers Association (VMA), nearly 60% of all industrial check valves in Europe are either cast iron or stainless steel, highlighting the dominance of these materials in performance-critical applications. The choice between the two often boils down to factors such as fluid type, pressure, temperature, environmental conditions, and long-term operational cost.

Material Properties and Performance

Cast Iron Check Valve Characteristics

Cast iron check valves are known for their mechanical strength, affordability, and resistance to abrasion. They are widely used in water distribution, sewage systems, and general industrial pipelines.

Key Performance Metrics:

- Compressive Strength: 150-300 MPa

- Maximum Working Pressure: 16-25 bar (depending on size)

- Operating Temperature: -10°C to 120°C

- Weight: Heavier than stainless steel counterparts

Expert Insight:

Dr. Thomas Reinhardt, a materials engineer at the European Valve Institute, notes: “Cast iron valves remain the go-to solution for municipal water systems due to their robustness and cost-effectiveness. However, corrosion is always a consideration, especially in aggressive or outdoor environments.”

Stainless Steel Check Valve Characteristics

Stainless steel check valves offer high corrosion resistance, long-term durability, and excellent performance in high-pressure and high-temperature conditions. They are preferred in chemical, food, and pharmaceutical industries.

Key Performance Metrics:

- Compressive Strength: 500-700 MPa

- Maximum Working Pressure: 25-40 bar

- Operating Temperature: -50°C to 400°C

- Weight: Lighter than cast iron relative to strength

Expert Insight:

Maria López, R&D director at Global Valve Solutions, explains: “Stainless steel valves are ideal where fluid purity and corrosion resistance are critical. While the initial cost is higher, total cost of ownership is often lower due to extended service life and reduced maintenance.”

Advantages and Disadvantages

Cast Iron Check Valve Pros and Cons

Vorteile:

- Cost-effective for large-scale applications

- Excellent mechanical strength

- Easy to cast in large diameters

Disadvantages:

- Moderate corrosion resistance

- Heavy weight increases handling and installation difficulty

- Limited temperature range

Stainless Steel Check Valve Pros and Cons

Vorteile:

- Superior corrosion resistance and chemical compatibility

- Can handle high temperatures and pressures

- Long lifespan and low maintenance

Disadvantages:

- Higher initial cost

- Complex casting process, especially for larger sizes

- Over-engineered for non-corrosive, low-pressure systems

Applications: Cast Iron vs Stainless Steel

Water and Wastewater Systems

Cast iron check valves are extensively used in municipal water supply, sewage systems, and irrigation pipelines. They offer durability and cost-efficiency for long pipelines. Stainless steel valves can be used in treated water pipelines or corrosive wastewater streams.

Chemische Verarbeitung

Stainless steel check valves are preferred due to resistance to acids, alkalis, and corrosive chemicals. Cast iron may be suitable for less aggressive chemical solutions but requires protective coatings.

Food and Pharmaceutical Applications

Regulatory requirements demand stainless steel check valves for hygienic performance, corrosion resistance, and easy cleaning. Cast iron is not suitable for these applications.

HVAC and Industrial Applications

Both materials can be used for heating, ventilation, and industrial piping systems. Cast iron is common for standard water pipelines, while stainless steel is suitable for high-temperature steam lines or aggressive fluids.

Installation and Maintenance Considerations

Installation Tips

- Cast Iron: Ensure proper alignment due to weight, use anti-corrosion coatings in outdoor environments.

- Edelstahl: Precision alignment is easier due to lighter weight; handle with care to avoid surface scratches that may affect corrosion resistance.

Maintenance Guidelines

- Cast Iron: Inspect annually for corrosion, sediment build-up, and wear; repaint exposed outdoor valves.

- Edelstahl: Minimal maintenance, periodic inspection of seals and mechanical components recommended.

Expert Tip: Proper installation often doubles the service life of valves. Incorrect torque, misalignment, or poor flange connections can lead to early failure.

Comparative Table of Cast Iron and Stainless Steel Check Valves

| Besonderheit | Cast Iron Check Valve | Stainless Steel Check Valve |

|---|---|---|

| Kosten | Niedrig | Hoch |

| Korrosionsbeständigkeit | Mäßig | Exzellent |

| Temperature Range | -10°C to 120°C | -50°C to 400°C |

| Pressure Rating | 16-25 bar | 25-40 bar |

| Gewicht | Heavier | Lighter |

| Wartung | Mäßig | Niedrig |

| Suitable Fluids | Water, wastewater | Chemicals, food, aggressive fluids |

| Lebensdauer | 15-25 years | 25-50 years |

Cost and ROI Considerations

While cast iron check valves have a lower upfront cost, stainless steel valves often provide better Gesamtbetriebskosten in harsh environments. A study by Industrial Valve Analytics 2024 found that stainless steel valves reduced maintenance costs by 30% over 10 years in chemical plants, offsetting initial higher purchase costs.

Case Studies: Real-World Applications

Municipal Water Project in Germany

A 2 km municipal pipeline used cast iron check valves. Initial cost savings were significant, but after 15 years, corrosion at certain junctions required partial replacements.

Chemical Plant in Spain

Stainless steel check valves were installed for aggressive chemical lines. Over 12 years, the valves required only minor seal maintenance, confirming their long-term ROI despite higher initial investment.

Food Processing Plant in Italy

Hygienic stainless steel check valves were used for dairy production lines. Easy cleaning, corrosion resistance, and compliance with food safety regulations ensured uninterrupted operations.

Factors to Consider When Choosing Between Cast Iron and Stainless Steel

- Fluid Type and Corrosiveness: Choose stainless steel for acids, alkalis, and chlorinated water.

- Operating Pressure and Temperature: Stainless steel supports higher pressures and temperatures.

- Budget vs Lifetime: Cast iron for short- to medium-term projects, stainless steel for long-term reliability.

- Installation Environment: Stainless steel is preferable for outdoor or humid conditions.

- Regulatory Requirements: Food, pharmaceutical, or chemical industries may mandate stainless steel.

Abschluss

Selecting the ideal check valve material is a balance between performance, cost, and application-specific requirements. Cast iron check valves remain a strong choice for cost-effective, non-corrosive applications, while stainless steel check valves excel in demanding environments where longevity, corrosion resistance, and hygiene are critical.

By considering factors such as fluid type, temperature, pressure, installation environment, and regulatory requirements, engineers and procurement teams can make informed decisions that maximize efficiency, reduce downtime, and provide long-term value.

Investing in high-quality valves from a reliable foundry ensures that whether you choose cast iron or stainless steel, your system will operate efficiently, safely, and reliably for years to come.

Häufig gestellte Fragen

Q: Can cast iron check valves handle corrosive fluids?

A: Only mild or treated fluids; for aggressive chemicals, stainless steel is recommended.

Q: What is the lifespan of cast iron valves?

A: Typically 15-25 years with proper maintenance.

Q: Are stainless steel valves worth the investment?

A: Yes, especially for long-term, high-performance, or corrosive applications.

Q: Can both types be cast in large diameters?

A: Yes, our foundry can cast both materials up to 600mm or customized sizes.

Q: Which valve is easier to install?

A: Stainless steel is lighter and easier to handle, but both require proper alignment.

Q: How do I maintain a cast iron check valve?

A: Inspect annually, clean sediments, and apply protective coatings if outdoors.

Q: Do stainless steel valves require frequent maintenance?

A: Minimal; mainly check seals and mechanical components.

Q: What industries prefer cast iron check valves?

A: Municipal water, wastewater, HVAC, irrigation, and general industrial pipelines.

Q: What industries prefer stainless steel check valves?

A: Chemical processing, pharmaceutical, food, marine, and high-temperature industrial pipelines.

Produktkategorien

- Ventilteile

- Wasserpumpenteile

- Lagergehäuseteile

- Druckgussteile

- Pumpenprodukte aus Edelstahl

- Pumpenprodukte aus Gusseisen

- Ventilteile für den Automobilgebrauch

- Autoteile

- Ventilteile für den zivilen Gebrauch

- Vakuumpumpenteile KF