7 Innovative Investment Casting Alloys Applications

Willkommen auf meinem Blog!

Ich freue mich sehr, dass du hier bist! Bevor wir uns in die Inhalte vertiefen, würde ich mich freuen, wenn du mir auf meinen Social-Media-Plattformen folgst. Dort teile ich zusätzliche Einblicke, vernetze mich mit unserer großartigen Community und halte dich über die neuesten Nachrichten auf dem Laufenden. So bleibst du in Verbindung:

📘 Facebook: Shanghai Leierwo Industriehandel Co., Ltd.

Lassen Sie uns gemeinsam auf diese Reise gehen! Ich hoffe, Sie finden die Inhalte hier nicht nur aufschlussreich, sondern auch inspirierend und wertvoll. Los geht‘s!

Inhaltsverzeichnis

Einführung

Investment casting alloys have long been an essential component in precision engineering and manufacturing. Their ability to deliver intricate shapes with excellent surface finish makes them indispensable in industries such as aerospace, automotive, and medical devices. The key to successful use lies not only in material selection but also in understanding how these alloys behave under different casting conditions. This article explores seven innovative applications of investment casting alloys, highlighting their advantages, limitations, and real-world examples.

Investment casting alloys are carefully engineered metals that provide a combination of strength, corrosion resistance, and dimensional stability. Choosing the right alloy impacts not only the performance but also the longevity of the final product.

What Are Investment Casting Alloys?

Investment casting alloys refer to metals specifically designed for the lost-wax casting process. Common types include:

- Stainless steel alloys

- Cobalt-chromium alloys

- Nickel-based superalloys

- Aluminiumlegierungen

- Copper-based alloys

Each alloy type provides unique mechanical and chemical properties suitable for different applications.

Why Innovation Matters in Investment Casting

Innovation in investment casting alloys is more than just developing new compositions—it’s about enhancing efficiency, reducing waste, and improving component performance. With continuous advancements in metallurgy and process technology, manufacturers can now produce parts that were previously impossible to achieve with traditional casting methods.

Some of the key benefits of innovation in investment casting alloys include:

- Material Optimization: Modern alloys are engineered to reduce scrap rates and minimize post-casting machining.

- Precision and Reliability: New alloy formulations improve dimensional stability and reduce the risk of defects such as porosity or cracking.

- Sustainability: Advanced alloys enable lighter, more energy-efficient components, contributing to environmental sustainability in aerospace, automotive, and industrial sectors.

- Cost Efficiency: Reducing post-processing requirements and increasing first-pass yield significantly lowers overall production costs.

Industry experts emphasize that combining innovative alloy design with precise casting techniques is critical to achieving high-performance components. For example, aerospace engineers often use nickel-based superalloys with controlled grain structures to improve turbine blade lifespan while maintaining resistance to extreme operational stress.

By staying at the forefront of alloy innovation, manufacturers can push the boundaries of what’s possible, producing complex, durable, and high-performing components across a wide range of industries.

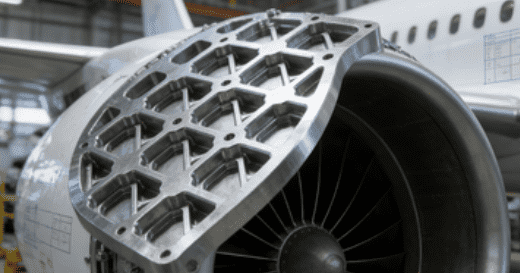

1. Aerospace Components

Investment casting alloys are indispensable in aerospace applications because of their exceptional strength-to-weight ratio, thermal resistance, and precision. Titanium and nickel-based superalloys are particularly favored for turbine blades, engine casings, and structural components, where even minor material failures could have catastrophic consequences.

Beispiel: The Boeing 787 Dreamliner incorporates nickel-based investment casting alloys in select engine parts, ensuring high-temperature stability, corrosion resistance, and long-term durability in extreme flight conditions.

Benefits in Aerospace:

- High-precision casting reduces or eliminates the need for extensive machining, saving both time and cost.

- Advanced alloy properties enable components to withstand extreme operational environments, including temperatures exceeding 1000°C.

- Optimized component design reduces overall aircraft weight, improving fuel efficiency and performance.

Brancheneinblicke: According to a 2021 study published in the Journal of Aerospace Materials, the use of nickel-based investment casting alloys in turbine components can extend operational lifespan by up to 30% compared to traditional materials.

2. Medical Devices

In medical technology, precision and biocompatibility are paramount. Investment casting alloys, especially cobalt-chromium and stainless steel, are widely used in surgical instruments, implants, and dental prosthetics.

Precision and Surface Finish: These alloys enable intricate, patient-specific designs that precisely match anatomical structures, ensuring optimal functionality and comfort.

Durability: High corrosion resistance ensures long-term stability within the human body, even in challenging biochemical environments.

Emerging Applications:

- The combination of 3D printing and investment casting alloys allows for rapid prototyping of patient-specific implants, reducing production time and improving accuracy.

- Hybrid approaches can create lightweight yet strong medical tools, combining the benefits of multiple alloy types.

Expertenmeinung: Dr. Emily Sanders, a biomedical engineer at the Medical Materials Institute, notes, “Cobalt-chromium alloys offer a unique balance of biocompatibility, wear resistance, and machinability, making them ideal for next-generation orthopedic implants.” combined with investment casting alloys is enabling hybrid medical devices, where prototypes can be tested before mass production.

3. Automotive and Transportation Parts

Modern vehicles demand lightweight, durable, and heat-resistant components, and investment casting alloys meet these requirements efficiently. Engine components, turbochargers, suspension parts, and braking system components often rely on aluminum alloys, stainless steel, or nickel-based alloys.

Key Advantages in Automotive Applications:

- Weight reduction improves fuel efficiency without compromising strength.

- Nickel-based alloys in turbochargers withstand extreme heat and rotational stress.

- Durable construction minimizes long-term maintenance and replacement costs.

Beispiel: High-performance sports cars often use investment-cast turbocharger housings made from nickel-based alloys to handle operating temperatures exceeding 900°C while maintaining dimensional stability.

Regional Preference: In Europe, lightweight aluminum-based investment casting alloys dominate automotive interior and engine components, while in Asia, nickel-based alloys are increasingly favored for high-performance and electric vehicle motors.

4. Energy and Power Generation

Investment casting alloys are crucial in power generation due to the demand for components that endure high temperature, pressure, and corrosive environments. Applications include gas turbines, steam turbines, nuclear reactors, and hydroelectric machinery.

- Nickel-based superalloys: Predominate in high-temperature turbine sections.

- Cobalt-chromium alloys: Ideal for wear-resistant components in hydraulic and rotating machinery.

Comparison Table: Common Investment Casting Alloys and Key Properties

| Alloy Type | Key Property | Häufige Anwendungen | Temperature Range |

|---|---|---|---|

| Edelstahl | Korrosionsbeständigkeit | Medical devices, automotive parts | -40°C to 800°C |

| Cobalt-Chromium | Wear resistance, biocompatible | Dental, implants, turbine parts | -50°C to 1000°C |

| Nickel-Based Superalloy | High temperature strength | Aerospace, turbines | -50°C to 1200°C |

| Aluminum Alloy | Lightweight, machinable | Automotive, machinery | -40°C to 600°C |

| Copper-Based Alloy | Thermal/electrical conductivity | Electrical connectors, tooling | -40°C to 400°C |

Data Insight: A 2022 study by Energy Materials Review found that replacing conventional cast components with investment casting alloys in gas turbines reduced maintenance downtime by 20% and increased thermal efficiency by 5%.

5. Marine and Offshore Applications

Saltwater and offshore environments are extremely corrosive, making Hochleistungslegierungen essential. Investment casting alloys like high-grade stainless steel and nickel-chromium are used for propellers, subsea valves, and ship structural components.

Vorteile:

- Exceptional resistance to pitting, crevice corrosion, and mechanical wear.

- Maintains dimensional and structural integrity under harsh underwater conditions.

- Extends service life and reduces the need for frequent replacements.

Beispiel: Offshore oil platforms often rely on nickel-based investment casting alloys for critical valves and pumps, ensuring reliable operation under high pressure and saltwater exposure.

Expertenmeinung: Marine metallurgists recommend using high-chromium stainless steel alloys for components exposed to tidal and wave forces to prevent long-term degradation.

6. Tooling and Industrial Machinery

Investment casting alloys are also widely used in precision tooling, dies, and molds, offering hardness, wear resistance, and thermal stability.

Key Benefits:

- Components made from cobalt-chromium alloys can endure thousands of operational cycles without significant wear.

- Dimensional stability is maintained under repeated thermal and mechanical stresses.

- Reduces downtime in industrial production lines, improving overall efficiency.

Beispiel: Automotive die-casting molds for engine components are commonly made from cobalt-chromium alloys, offering both strength and surface precision for mass production.

7. Art and Decorative Castings

Investment casting alloys are not limited to industrial applications—they also enable high-detail artistic and decorative castings. Bronze, copper, and stainless steel alloys allow designers to create durable, aesthetically pleasing sculptures, architectural elements, and hardware.

Vorteile:

- Supports intricate designs and complex geometries that are difficult to achieve with traditional metalworking.

- Corrosion-resistant alloys ensure outdoor installations retain appearance and durability for decades.

- Combines artistic freedom with mechanical reliability, making it ideal for public art installations.

Beispiel: Large bronze statues in urban parks are often produced using investment casting alloys, ensuring both longevity and intricate detailing.

Abschluss

Investment casting alloys continue to shape the future of engineering and design. From aerospace to medical devices, automotive components, and artistic creations, the versatility and precision of these alloys make them indispensable. Understanding the right alloy for each application ensures high performance, longevity, and cost efficiency.

Häufig gestellte Fragen

Q1: What are the most commonly used investment casting alloys?

A: Stainless steel, cobalt-chromium, nickel-based superalloys, aluminum, and copper alloys are the most common.

Q2: Can investment casting alloys be used for high-temperature applications?

A: Yes, nickel-based superalloys and cobalt-chromium alloys perform well in extreme temperatures.

Q3: How precise can investment casting alloys be molded?

A: They can achieve dimensional tolerances within 0.1 mm for intricate components.

Q4: Are investment casting alloys suitable for medical implants?

A: Yes, biocompatible alloys like cobalt-chromium and stainless steel are widely used.

Q5: What industries benefit most from investment casting alloys?

A: Aerospace, automotive, medical, energy, marine, industrial tooling, and decorative arts.

Q6: How do I choose the right alloy for my project?

A: Consider operating temperature, corrosion resistance, mechanical strength, and precision requirements.

Produktkategorien

- Ventilteile

- Wasserpumpenteile

- Lagergehäuseteile

- Druckgussteile

- Pumpenprodukte aus Edelstahl

- Pumpenprodukte aus Gusseisen

- Ventilteile für den Automobilgebrauch

- Autoteile

- Ventilteile für den zivilen Gebrauch

- Vakuumpumpenteile KF