4 Powerful 3D Printing Trends for 2026

Willkommen auf meinem Blog!

Ich freue mich sehr, dass du hier bist! Bevor wir uns in die Inhalte vertiefen, würde ich mich freuen, wenn du mir auf meinen Social-Media-Plattformen folgst. Dort teile ich zusätzliche Einblicke, vernetze mich mit unserer großartigen Community und halte dich über die neuesten Nachrichten auf dem Laufenden. So bleibst du in Verbindung:

📘 Facebook: Shanghai Leierwo Industriehandel Co., Ltd.

Lassen Sie uns gemeinsam auf diese Reise gehen! Ich hoffe, Sie finden die Inhalte hier nicht nur aufschlussreich, sondern auch inspirierend und wertvoll. Los geht‘s!

Inhaltsverzeichnis

Einführung

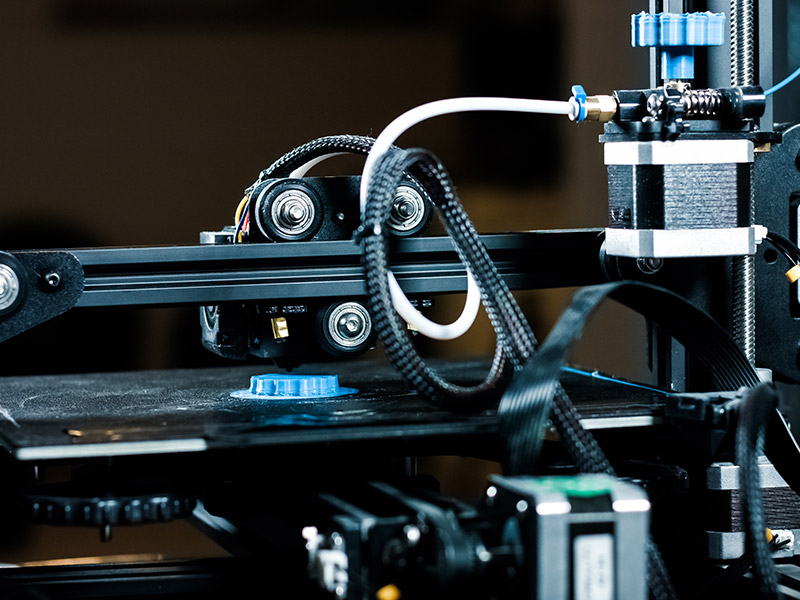

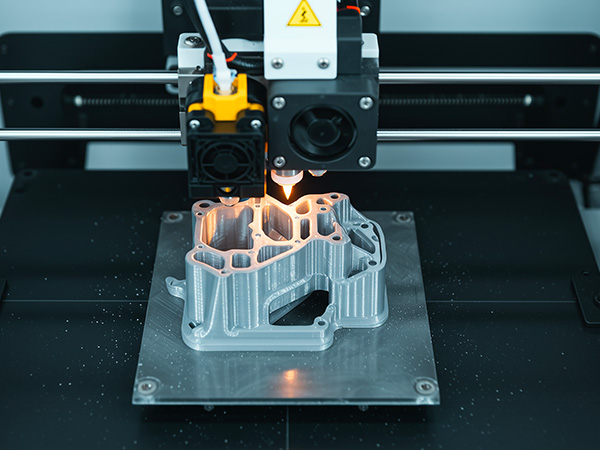

3D-Druck, also known as additive manufacturing, is transforming the manufacturing landscape at an unprecedented rate. By 2026, it is expected to dominate industries from aerospace and automotive to healthcare and consumer products. Unlike traditional manufacturing, 3D Printing builds objects layer by layer, enabling complex geometries, faster prototyping, and highly customizable production.

In this comprehensive article, you will learn:

- Der top 4 3D Printing trends for 2026 and their real-world implications

- Advantages and challenges of each trend, backed by authoritative data

- Comparisons of 3D Printing with traditional manufacturing methods

- Industry-specific case studies illustrating cost reduction, efficiency, and innovation

- FAQs and practical guidance for adopting these trends

- Expert opinions and insights from leading researchers and engineers

By the end, you will understand how to leverage these trends to improve productivity, sustainability, and competitiveness in your business.

Additive Manufacturing Goes Mainstream

Concept: Industrial Adoption Across Sectors

Additive manufacturing is no longer experimental. In aerospace, companies like Boeing and Airbus are now producing over 50,000 3D-printed parts annually, from engine components to brackets. According to Wohlers Report 2025, more than 80% of aerospace companies are integrating additive manufacturing into functional production, reducing prototyping cycles and material waste.

Benefits of Mainstream Adoption

- Faster lead times: Traditional methods can take 4–8 weeks; 3D Printing reduces this to 1–2 days for prototypes.

- Mass customization: Each part can be tailored to customer specifications without raising costs.

- Inventory optimization: Producing on-demand reduces storage and logistics expenses.

Traditional vs Additive Manufacturing Comparison

| Besonderheit | Traditional Manufacturing | 3D-Druck | Notes |

|---|---|---|---|

| Lieferzeit | 4–8 weeks | 1–2 days | Faster design iterations enable rapid innovation |

| Materialabfall | Hoch | Niedrig | Additive layer-by-layer method uses only required material |

| Complexity | Beschränkt | Sehr hoch | Complex geometries possible only with 3D Printing |

| Cost for Low Volume | Hoch | Niedrig | Ideal for small-batch or custom production |

Expert Insight: “Additive manufacturing allows rapid design validation while maintaining structural performance, which is a game-changer for product development,” says Dr. Jennifer A. Lewis, Harvard SEAS.

Multi-Material and Functional Printing

Concept: Combining Multiple Materials

By 2026, multi-material 3D-Druck will enable the creation of single components with varying properties. Printers can now combine metals, polymers, ceramics, and composites in one print. Functional parts may also integrate electronics, sensors, or conductive pathways without additional assembly.

Benefits

- Produces ready-to-use, highly functional parts

- Reduces assembly time and post-processing

- Enables smart and embedded technologies in a single component

Practical Industry Applications

- Aerospace brackets with embedded wiring printed in one operation

- Robotic grippers combining flexible joints and rigid components

- Wearable medical devices with integrated soft sensors

Comparison: Single vs Multi-Material

| Besonderheit | Single Material | Multi-Material | Notes |

|---|---|---|---|

| Designflexibilität | Mäßig | Hoch | Multi-material allows complex functional parts |

| Post-Processing | Required | Minimal | Reduces labor and assembly |

| Embedded Electronics | No | Ja | Enables smart, connected devices |

Sustainable 3D Printing Practices

Concept: Eco-Friendly Manufacturing

Sustainability is a growing priority. Companies are adopting recycled filaments, biodegradable polymers, and energy-efficient printing methods. According to a 2025 ASTM study, switching from traditional injection molding to recycled 3D Printing materials can reduce CO2 emissions by up to 40%.

Benefits

- Reduces material waste and energy consumption

- Supports corporate sustainability initiatives

- Meets growing consumer demand for eco-conscious products

Key Industry Insights

- Nike and Adidas are experimenting with 3D-printed shoe soles made from recycled plastics.

- GE Aviation uses recycled metal powders to reduce waste by 25% while maintaining high-strength components.

Materials Innovations

- PLA and PHA polymers: Biodegradable and suitable for lightweight parts

- Recycled PET: Cost-effective and environmentally friendly

- Metal powders: Can be reused multiple times in laser sintering, reducing material costAI-Driven and Automated 3D-Druck

Concept: Intelligent Manufacturing

Artificial intelligence enhances 3D Printing by optimizing toolpaths, predicting thermal distortions, and detecting defects in real time. Automated systems reduce human error, improve efficiency, and maintain consistent part quality.

Benefits

- Higher first-time-right print success rate

- Reduced operator intervention

- Optimized material usage and energy efficiency

Comparison: Manual vs AI-Driven Printing

| Besonderheit | Manual 3D Printing | AI-Driven 3D Printing | Notes |

|---|---|---|---|

| Print Accuracy | Mäßig | Hoch | AI compensates for warping and shrinkage |

| Human Intervention | Hoch | Niedrig | Automation reduces labor costs |

| Material Efficiency | Standard | Advanced | AI minimizes waste and energy usage |

Expert Insight: Entsprechend MIT CSAIL, AI-assisted 3D-Druck can reduce print failures by up to 60%, dramatically cutting costs and waste in industrial production.

Emerging Materials and Techniques

Metal Additive Manufacturing

- LPBF and DED: Produce aerospace-grade metal components with minimal post-processing

- Lightweight engine brackets and structural parts with high mechanical strength

Bioprinting and Healthcare

- Tissue scaffolds and implants: Customized prosthetics and regenerative medicine solutions

- Reduces surgery preparation time and improves patient outcomes

Composite and Carbon Fiber Printing

- Carbon fiber reinforced filaments provide superior strength-to-weight ratios

- Used in drones, automotive panels, and sports equipment for performance optimization

Mass Customization and On-Demand Production

- Consumer Products: Personalized jewelry, sneakers, and home décor

- Medical: Patient-specific prosthetics, dental crowns, and surgical guides

- Automotive and Aerospace: Small-batch or specialized components without tooling costs

Vorteile:

- Reduces inventory costs and overproduction

- Meets growing demand for personalized products

- Shortens product launch cycles significantly

3D-Druck in Extreme Environments

- Space Applications: NASA and ESA are experimenting with in-orbit 3D Printing for spacecraft parts

- Underwater and Subsea: Custom parts printed on-demand for maintenance and repairs

- High-Temperature Applications: Metal and ceramic printing for industrial furnaces and aerospace components

Expert Insight: “3D Printing in space and extreme environments allows mission-critical components to be produced on-site, avoiding supply chain delays,” says Dr. Mark Weislogel, NASA engineer.

Industry Applications

Aerospace and Defense

- Engine components, brackets, and ducts

- Reduces part weight by up to 30%

- Accelerates prototyping and production timelines

Automobilindustrie

- Lightweight housings, brackets, and tooling

- Increases fuel efficiency and reduces assembly costs

- Allows rapid iteration of concept models

Medical and Dental

- Prosthetics, implants, and surgical guides

- Personalized patient fit improves outcomes

- Faster production and lower costs

Consumer Products

- Custom sneakers, jewelry, and décor

- High personalization with low inventory

- On-demand production for market responsiveness

Productivity, Efficiency, and ROI

Efficiency Gains

- 3D Printing can reduce prototyping lead times by 50–70%

- Automated AI-driven systems minimize human intervention

Energy Efficiency

- Modern printers consume 30–40% less energy per part than older models

- AI optimization reduces material usage and motor load

Return on Investment

- Medium-sized manufacturers can see ROI in 12–18 months

- Faster time-to-market, reduced waste, and labor savings contribute to profitability

Safety and Compliance

- Proper ventilation for polymer and metal powders

- Protective equipment and training for operators

- Compliance with ISO/ASTM standards and EU REACH

- Stage V emissions compliance for industrial machines

Abschluss

Der 4 powerful 3D Printing trends for 2026—mainstream adoption, multi-material printing, sustainability, and AI-driven automation—are reshaping global manufacturing. Businesses that embrace these trends can reduce costs, increase efficiency, and deliver high-quality, customized products faster than ever. Understanding materials, technology, and industry applications will be critical for companies seeking a competitive edge in the next generation of manufacturing.

Key Takeaway: 3D-Druck is no longer optional. Integrating innovation, efficiency, and sustainability positions businesses for success in the rapidly evolving industrial landscape.

Häufig gestellte Fragen

Q1: Is 3D-Druck faster than traditional methods?

A: For prototypes and low-volume custom parts, yes. Mass production may still favor traditional methods.

Q2: Can 3D Printing produce functional metal parts?

A: Yes. LPBF and DED allow aerospace-grade metal printing with high strength.

Q3: Are 3D-printed parts durable?

A: With the right materials and post-processing, printed components can match or exceed traditional parts.

Q4: How does AI improve print quality?

A: AI predicts warping, adjusts paths, and optimizes material usage for higher accuracy.

Q5: Can 3D Printing reduce environmental impact?

A: Yes. Using recycled or biodegradable materials, additive manufacturing reduces waste and energy consumption.

Q6: What industries will benefit most by 2026?

A: Aerospace, automotive, medical, dental, robotics, and consumer goods.

Q7: How cost-effective is multi-material printing?

A: While upfront costs are higher, reduced assembly and faster time-to-market provide strong ROI.

Q8: Will 3D Printing replace CNC and injection molding?

A: Not completely. It complements them for complex, small-batch, or customized parts.

Q9: How safe is printing with metal powders?

A: With proper ventilation, protective equipment, and training, risks are manageable.

Q10: How can small businesses adopt AI-driven printing?

A: Entry-level AI-enabled printers are now available, making automation and optimization accessible even for SMEs.

Produktkategorien

- Ventilteile

- Wasserpumpenteile

- Lagergehäuseteile

- Druckgussteile

- Pumpenprodukte aus Edelstahl

- Pumpenprodukte aus Gusseisen

- Ventilteile für den Automobilgebrauch

- Autoteile

- Ventilteile für den zivilen Gebrauch

- Vakuumpumpenteile KF