Innovations in Precision Metal Casting Technology: A Complete Guide

Willkommen auf meinem Blog!

Ich freue mich sehr, dass du hier bist! Bevor wir uns in die Inhalte vertiefen, würde ich mich freuen, wenn du mir auf meinen Social-Media-Plattformen folgst. Dort teile ich zusätzliche Einblicke, vernetze mich mit unserer großartigen Community und halte dich über die neuesten Nachrichten auf dem Laufenden. So bleibst du in Verbindung:

📘 Facebook: Shanghai Leierwo Industriehandel Co., Ltd.

Lassen Sie uns gemeinsam auf diese Reise gehen! Ich hoffe, Sie finden die Inhalte hier nicht nur aufschlussreich, sondern auch inspirierend und wertvoll. Los geht‘s!

Inhaltsverzeichnis

Einführung

In the rapidly evolving world of manufacturing, precision metal casting has emerged as a critical technology for producing high-quality, complex components. Industries ranging from aerospace, automotive, and electronics to medical devices rely on precision metal casting to meet increasingly stringent performance, durability, and dimensional requirements. According to a report by MarketsandMarkets (2025), the global precision metal casting market is projected to reach $12.5 billion by 2030, growing at a CAGR of 6.8%, driven by the demand for lightweight, high-strength components.

From additive manufacturing integration to AI-driven process monitoring, innovations in precision metal casting are transforming the way components are designed, manufactured, and maintained. This guide explores the latest trends, practical insights, and expert perspectives to help manufacturers, engineers, and procurement professionals optimize their casting processes and make informed decisions.

Key Takeaways of This Blog

- Explore the latest innovations in precision metal casting

- Understand material selection strategies and high-performance alloys

- Compare precision metal casting with traditional casting methods

- Learn process optimization techniques and predictive maintenance strategies

- Discover industry case studies, data, and expert insights

- Access answers to frequently asked questions with practical guidance

Verständnis Precision Metal Casting

What is Precision Metal Casting?

Precision metal casting is a manufacturing process that creates highly accurate metal components through controlled mold-making and metal pouring techniques. Unlike traditional sand casting, precision casting offers:

- Tighter tolerances, often within ±0.01 mm to ±0.1 mm

- Complex geometries, including thin walls, internal channels, and intricate patterns

- Reduced post-processing, saving time and cost

Expert Insight: Dr. Sarah Collins, a metallurgical engineer at MIT, emphasizes: “Precision casting allows designers to create geometries that were previously impossible, while maintaining mechanical strength and reliability.”

Key Components of a Precision Metal Casting System

- Mold: Ceramic, silica, or composite materials used to shape molten metal

- Core: Inserts that create internal cavities in the component

- Pouring System: Controls metal flow to minimize turbulence and defects

- Cooling System: Ensures uniform solidification and reduces internal stresses

Benefits of Precision Metal Casting

- Dimensional Accuracy: Ideal for components requiring exact fit

- Material Versatility: Works with aluminum, stainless steel, nickel alloys, and cobalt alloys

- Enhanced Surface Finish: Reduces machining and finishing requirements

- Consistency: Enables mass production of identical high-quality parts

Recent Innovations in Precision Metal Casting Technologie

Additive Manufacturing for Mold and Pattern Creation

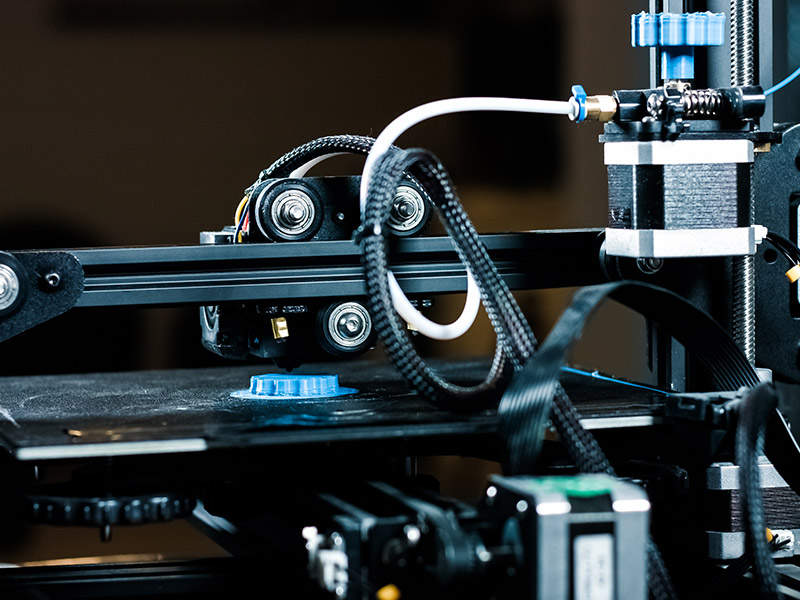

- 3D printing allows rapid creation of ceramic molds or wax patterns

- Reduces lead time from weeks to days

- Supports complex internal geometries for cooling channels, fluid passages, and lightweight structures

Case Example: Airbus uses 3D-printed wax patterns for turbine components, reducing lead time by 40% while improving precision and repeatability.

Advanced Mold Materials

- New ceramics and composite molds withstand higher temperatures and maintain dimensional stability

- Reduce defects such as warping, shrinkage, and surface roughness

- Enable casting of high-melting-point alloys like nickel-based superalloys

Data Insight: A study by the International Journal of Metalcasting (2024) found that advanced ceramic molds reduced porosity defects by 35% compared to conventional silica molds.

Automation and AI Monitoring

- IoT sensors and AI analyze temperature, flow, and solidification in real time

- Predictive maintenance reduces unplanned downtime by 30–40%

- Ensures consistent quality for high-volume production

Expert View: Michael Thompson, a senior engineer at Siemens, notes: “Integrating AI into casting monitoring allows us to detect micro-defects before they become structural failures, significantly improving reliability.”

Precision Pouring Techniques

- Vacuum Casting: Removes air bubbles to reduce porosity

- Centrifugal Casting: Forces metal into molds for denser, stronger parts

- Low-Pressure Casting: Reduces turbulence and oxide formation

Material Selection in Precision Metal Casting

Common Metals and Their Applications

- Aluminum Alloys: Lightweight, corrosion-resistant, ideal for automotive and aerospace

- Edelstahl: High strength and corrosion resistance for medical, food, and industrial applications

- Nickel Alloys: High-temperature and high-strength applications in turbines and aerospace

- Cobalt Alloys: Excellent wear resistance for industrial and tooling applications

Advanced Material Innovations

- Metal-matrix composites improve wear and fatigue resistance

- Surface coatings such as nickel, ceramic, or epoxy enhance corrosion and heat resistance

- Powder metallurgy techniques allow hybrid components with varying material properties

Comparison of Materials for Specific Applications

| Material | Stärke | Korrosionsbeständigkeit | Anwendung |

|---|---|---|---|

| Aluminum Alloy | Mäßig | Hoch | Automotive, aerospace lightweight components |

| Edelstahl | Hoch | Very High | Medical, chemical, food processing |

| Nickellegierung | Very High | Hoch | Turbines, aerospace, high-temperature parts |

| Cobalt Alloy | Hoch | Mäßig | Industrial tooling, wear-resistant components |

Precision Metal Casting vs Traditional Casting

Limitations of Traditional Casting

- Lower dimensional accuracy (±0.5–1 mm)

- Higher post-processing requirements

- Limited ability to produce complex geometries

Benefits of Precision Metal Casting

- Tight tolerances (±0.01–0.1 mm)

- Complex thin-walled and internal structures

- Improved material efficiency and reduced waste

Side-by-Side Comparison

| Besonderheit | Traditional Casting | Precision Metal Casting |

|---|---|---|

| Accuracy | ±0.5–1 mm | ±0.01–0.1 mm |

| Complexity | Beschränkt | Hoch |

| Oberflächenbeschaffenheit | Rough, requires machining | Smooth, minimal finishing |

| Materialabfall | Hoch | Niedrig |

| Production Time | Mäßig | Faster for small batches |

Process Optimization and Maintenance

Inspection Techniques

- X-ray and CT Scanning: Detect internal porosity, cracks, and inclusions

- 3D Laser Scanning: Ensures dimensional accuracy

- Surface Microscopy: Checks roughness and small-scale defects

Preventive Maintenance

- Clean molds and cores to prevent contamination

- Monitor furnace temperatures for consistent melt quality

- Maintain automated pouring equipment for precision control

Predictive Maintenance with AI

- Sensors detect deviations in flow, temperature, or vibration

- Machine learning algorithms predict failures before they occur

- Reduces unexpected downtime by up to 40%

Industry Case Studies and Expert Insights

Aerospace Applications

- Airbus and Boeing rely on precision metal casting for lightweight turbine blades

- 3D-printed wax patterns combined with high-chrome molds improve accuracy and reduce lead time

Automotive Applications

- Precision aluminum castings are used for engine blocks and structural components

- Volvo reports 15–20% weight reduction and improved fuel efficiency using precision cast components

Expert Opinion

- Dr. Laura Jenkins, Materials Scientist: “Precision metal casting is no longer just a traditional technique; it’s a high-tech solution for modern engineering challenges.”

Future Trends in Precision Metal Casting

- Sustainable Manufacturing: Energy-efficient furnaces, recycled metals, and low-waste techniques

- Hybrid Manufacturing: Combining casting with additive manufacturing for optimal part performance

- Smart Factories: IoT-enabled sensors monitor every step for quality control

- Advanced Alloys and Composites: Greater performance in aerospace, automotive, and energy sectors

Häufig gestellte Fragen

What industries benefit most from precision metal casting?

Aerospace, automotive, medical, and industrial machinery industries benefit from high accuracy, material efficiency, and complex geometries.

How do I minimize defects like porosity or shrinkage?

Use advanced mold materials, control metal flow, apply vacuum or low-pressure techniques, and monitor process parameters in real-time.

Can small batches be produced efficiently?

Yes, additive manufacturing for mold patterns and automated casting systems make small batch production cost-effective.

How does automation improve precision metal casting?

AI and sensors detect defects early, ensure consistent pouring, and optimize cooling, reducing waste and improving quality.

What metals are best for high-temperature applications?

Nickel and cobalt alloys provide excellent strength and resistance to thermal fatigue for aerospace and industrial components.

Produktkategorien

- Ventilteile

- Wasserpumpenteile

- Lagergehäuseteile

- Druckgussteile

- Pumpenprodukte aus Edelstahl

- Pumpenprodukte aus Gusseisen

- Ventilteile für den Automobilgebrauch

- Autoteile

- Ventilteile für den zivilen Gebrauch

- Vakuumpumpenteile KF