7 Ultimate Advantages of Stainless Steel Investment Casting

Willkommen auf meinem Blog!

Ich freue mich sehr, dass du hier bist! Bevor wir uns in die Inhalte vertiefen, würde ich mich freuen, wenn du mir auf meinen Social-Media-Plattformen folgst. Dort teile ich zusätzliche Einblicke, vernetze mich mit unserer großartigen Community und halte dich über die neuesten Nachrichten auf dem Laufenden. So bleibst du in Verbindung:

📘 Facebook: Shanghai Leierwo Industriehandel Co., Ltd.

Lassen Sie uns gemeinsam auf diese Reise gehen! Ich hoffe, Sie finden die Inhalte hier nicht nur aufschlussreich, sondern auch inspirierend und wertvoll. Los geht‘s!

Inhaltsverzeichnis

Einführung

In modern manufacturing, precision and reliability are paramount. Stainless steel investment casting has emerged as a game-changing solution for industries demanding high-quality, complex, and durable components. From aerospace to medical devices, automotive to energy equipment, this process allows manufacturers to achieve superior performance without compromising on design flexibility or material properties.

This comprehensive guide will cover:

- Key advantages of stainless steel investment casting

- How it compares to other metal forming methods

- Material selection and design flexibility

- Cost efficiency and production scalability

- Surface finish and precision benefits

- Mechanical properties and durability

- Industry applications and real-world use cases

- Frequently asked questions (FAQ) from engineers and buyers

Was ist Edelstahl-Feinguss?

Concept and Process

Stainless steel investment casting, also known as lost-wax casting, involves creating a wax pattern that is coated with a ceramic shell. Once the shell hardens, the wax is melted out and replaced with molten stainless steel. The ceramic shell is then broken to reveal the finished part.

Warum es wichtig ist

This process allows manufacturers to produce components with intricate geometries, thin walls, and tight tolerances, which are often impossible with traditional sand casting or die casting. It is particularly favored in applications where precision, corrosion resistance, and mechanical reliability are critical.

Expert Insight

Dr. Robert Lin, Materials Engineer at Advanced Casting Solutions, notes:

“Investment casting allows us to achieve dimensional accuracy and surface quality that is often unattainable through machining or other conventional methods. For aerospace and medical applications, it’s a non-negotiable process.”

High Precision and Accuracy

Tighter Tolerances

Investment casting can achieve tolerances as low as ±0.1 mm for medium-sized components. This high precision minimizes the need for post-processing, reducing labor costs and production time.

Consistent Reproduction

One of the major advantages is repeatability. Multiple parts produced from the same mold maintain near-identical dimensions, which is essential for assembly lines and automated systems.

Comparison With Machining

| Method | Typical Tolerance | Post-Processing Required | Kosten |

|---|---|---|---|

| Feinguss | ±0.1 mm | Minimal | Medium |

| CNC-Bearbeitung | ±0.05 mm | Mäßig | Hoch |

| Sandguss | ±0.5 mm | Umfangreich | Niedrig |

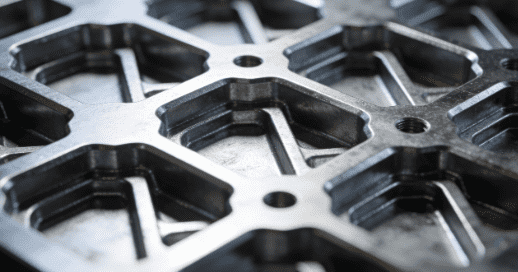

Complex Geometries Made Simple

Designflexibilität

Stainless steel investment casting allows manufacturers to create thin walls, undercuts, and hollow sections without additional assembly. This flexibility reduces the number of components required in a final assembly.

Reduced Assembly Needs

Producing complex components as a single piece reduces welds, fasteners, or joints, which not only lowers labor but also minimizes potential points of failure in high-stress applications.

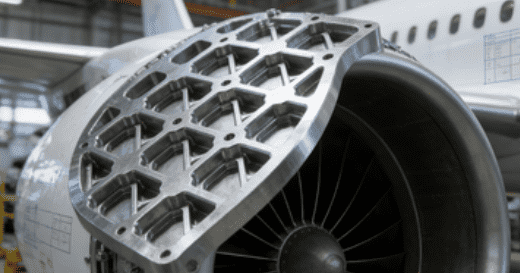

Case Study

An aerospace company successfully replaced a 5-piece assembly in a turbine with a single stainless steel investment cast component, reducing assembly time by 40% and increasing overall durability.

Excellent Mechanical Properties

Festigkeit und Haltbarkeit

Stainless steel alloys such as 17-4 PH and duplex stainless steel exhibit high tensile strength (up to 1,000 MPa) and yield strength while maintaining ductility.

Corrosion and Wear Resistance

Investment-cast parts offer uniform grain structure and fewer internal defects compared to machined or sand-cast components, resulting in superior wear resistance. This makes them ideal for marine, chemical, and high-temperature environments.

Material Comparison Table

| Legierung | Zugfestigkeit (MPa) | Hardness (HRC) | Korrosionsbeständigkeit |

|---|---|---|---|

| 304 | 520 | 85 | Exzellent |

| 316 | 580 | 87 | Superior in chemical & marine |

| 17-4 PH | 1,000 | 45-50 | High strength & moderate corrosion |

| Duplex | 850-1,000 | 40-45 | Excellent combination of strength & corrosion |

Superior Surface Finish

Smooth and Uniform Surfaces

Typical surface roughness (Ra) ranges between 0.8–1.6 μm, which reduces finishing requirements. Polishing, plating, or coating processes are often simplified.

Dimensional Accuracy

Precise wax patterns and ceramic molds ensure parts meet strict engineering specifications without excessive post-machining.

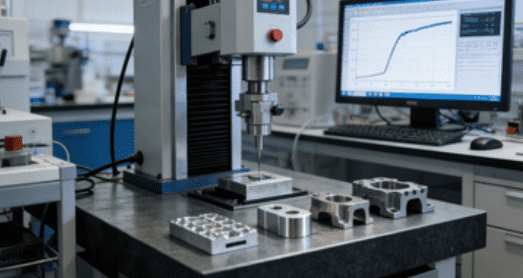

Enhanced Quality Control

High-quality investment casting enables automated inspection and digital measurement techniques to ensure every part adheres to strict standards.

Materialvielfalt

Wide Range of Stainless Steel Alloys

Investment casting supports alloys including 304, 316, 17-4 PH, duplex, and super duplex steels. Each material offers unique advantages in strength, corrosion resistance, and thermal performance.

Tailored Properties

Manufacturers can select alloys based on environmental conditions, load requirements, or chemical exposure. For instance, 316 is used in marine applications due to superior corrosion resistance, while 17-4 PH is preferred for aerospace parts requiring high tensile strength.

Applications Table

| Legierung | Recommended Applications | Key Benefits |

|---|---|---|

| 304 | Food processing, general machinery | Corrosion resistance, low cost |

| 316 | Chemical, marine, medical | Superior chemical resistance |

| 17-4 PH | Aerospace, tooling | High strength and hardness |

| Duplex | Offshore, chemical processing | Strength + corrosion resistance |

Cost Efficiency in Production

Minimal Waste

Unlike subtractive manufacturing, investment casting produces near-net-shape components, significantly reducing scrap metal and material costs.

Skalierbarkeit

The process works efficiently for small batches and large-scale production, maintaining consistent quality.

Comparative Analysis

| Verfahren | Materialabfall | Labor Required | Cost per Part | Ideal Volume |

|---|---|---|---|---|

| Feinguss | Niedrig | Mäßig | Medium | Small to medium |

| CNC-Bearbeitung | Hoch | Hoch | Hoch | Klein |

| Sandguss | Medium | Niedrig | Niedrig | Large |

Expert Opinion

According to James Carter, Production Manager at Global Casting Solutions:

“Investment casting allows us to produce complex parts with less material waste, reducing both costs and environmental impact.”

Broad Industrial Applications

Aerospace and Automotive Applications

Edelstahl-Feinguss is extensively used in the aerospace and automotive industries due to its high precision, corrosion resistance, and ability to produce lightweight yet strong components. Aerospace engines, turbine blades, exhaust manifolds, and structural brackets benefit from the ability to cast complex geometries that would be difficult or impossible to achieve with traditional machining.

In automotive applications, components like high-performance engine parts, transmission components, and suspension brackets require dimensional accuracy and mechanical reliability. Stainless Steel Investment Casting enables manufacturers to reduce assembly steps by producing multi-functional parts as a single cast, saving both time and cost.

Medical and Food Industry Applications

Der biocompatibility and corrosion resistance of stainless steel alloys produced via Stainless Steel Investment Casting make them ideal for medical and food processing equipment. Surgical tools, dental implants, orthopedic devices, and sterile processing equipment benefit from smooth surfaces, complex geometries, and reliable mechanical properties.

In the food industry, parts such as cutting blades, conveyor components, and valves must withstand frequent cleaning, high temperatures, and exposure to chemicals. Stainless Steel Investment Casting ensures clean, precise edges Und durable performance under these demanding conditions, reducing contamination risk and prolonging equipment life.

Energy and Industrial Equipment Applications

In energy generation, chemical processing, and heavy industrial sectors, Stainless Steel Investment Casting is critical for producing high-strength, heat-resistant components such as pump impellers, turbine components, valves, and chemical reactor fittings.

These components often operate under extreme conditions—high pressure, elevated temperature, or corrosive environments. Investment-cast stainless steel parts provide consistent material properties, low porosity, and exceptional durability, making them ideal for long-term industrial performance. Manufacturers rely on Stainless Steel Investment Casting to reduce maintenance frequency and prevent costly downtime.

Other Niche Applications

Beyond these primary sectors, Stainless Steel Investment Casting also finds use in the oil and gas industry, marine engineering, Und precision tooling. For example, offshore components such as propeller shafts, pump housings, and valve bodies must endure saltwater corrosion and mechanical stress. Here, Stainless Steel Investment Casting ensures both precision and long-term reliability.

Emerging Trends in Stainless Steel Investment Casting

Integration with 3D Printing

One of the most exciting trends in Edelstahl-Feinguss is the integration of additive manufacturing for wax pattern production. Using 3D printing to create wax or polymer patterns accelerates prototyping, shortens lead times, and allows for rapid iteration of complex designs without the need for expensive tooling.

Manufacturers can now produce customized, low-volume components more efficiently, making Stainless Steel Investment Casting viable for both large-scale production and highly specialized applications. According to industry reports, adoption of 3D printing in investment casting can reduce production lead times by up to 50%, especially for aerospace and medical components.

Sustainability Practices in Casting

Sustainability is becoming a major focus in Stainless Steel Investment Casting operations. Modern foundries are increasingly using recycled stainless steel, as well as reusable ceramic shells, which significantly reduces waste and environmental impact.

Energy-efficient furnaces, closed-loop water systems, and waste recovery programs are helping to lower the carbon footprint of investment casting processes. Manufacturers can now produce environmentally responsible components without compromising quality, precision, or mechanical strength, reinforcing the role of Stainless Steel Investment Casting in sustainable manufacturing.

Automation and Digital Quality Control

Digitalization is transforming Stainless Steel Investment Casting quality control. Laser scanning, high-resolution 3D imaging, and AI-driven defect detection allow for real-time monitoring of castings, ensuring uniformity and reducing rejection rates.

Predictive maintenance systems integrated into casting lines monitor furnace conditions, mold quality, and cooling rates, enabling operators to anticipate issues before they affect production. This integration of technology ensures consistent quality for complex investment-cast parts, whether they are for aerospace, medical, or industrial applications.

Enhanced Design Flexibility Through Advanced Simulation

Advanced software and simulation tools are allowing engineers to optimize designs for Stainless Steel Investment Casting, predicting shrinkage, stress distribution, and thermal behavior before any metal is poured.

This reduces trial-and-error in prototyping, lowers costs, and shortens development cycles. As industries demand more intricate and lightweight components, the combination of simulation with Stainless Steel Investment Casting ensures high-performance parts with fewer production defects.

Global Industry Adoption

Worldwide, manufacturers are increasingly adopting Stainless Steel Investment Casting for critical high-performance applications. From aerospace hubs in the U.S. and Europe to medical device production in Asia, the technology is recognized for precision, repeatability, and long-term reliability.

By combining 3D printing, sustainable practices, automation, and simulation, Stainless Steel Investment Casting is positioned as a cornerstone technology for modern engineering and advanced manufacturing.

Abschluss

Stainless steel investment casting offers precision, durability, material versatility, cost efficiency, and superior surface quality. By leveraging the 7 ultimate advantages, engineers and manufacturers can produce complex, high-performance components for demanding industries.

Whether you are designing turbine blades, surgical tools, or chemical processing equipment, this process ensures consistent quality, reduced production costs, and long-term reliability.

Häufig gestellte Fragen

What is the typical tolerance for stainless steel investment casting?

Tolerances are often ±0.1 mm, depending on part size and geometry.

How does it compare to CNC machining?

It reduces material waste, produces complex shapes in one piece, and requires less post-processing, while CNC machining offers slightly higher precision but higher cost.

Can it handle high-volume production?

Yes, it scales efficiently for hundreds to thousands of components annually without compromising quality.

What are the limitations?

Parts exceeding 500 kg may be challenging, and thin-walled designs require careful process control.

Ist stainless steel investment casting umweltfreundlich?

It reduces waste compared to subtractive manufacturing and supports reusable molds, making it more sustainable than machining solid blocks.

Which alloys are most popular?

304, 316, 17-4 PH, and duplex stainless steels are widely used, each selected for corrosion resistance, strength, and specific application requirements.

Produktkategorien

- Ventilteile

- Wasserpumpenteile

- Lagergehäuseteile

- Druckgussteile

- Pumpenprodukte aus Edelstahl

- Pumpenprodukte aus Gusseisen

- Ventilteile für den Automobilgebrauch

- Autoteile

- Ventilteile für den zivilen Gebrauch

- Vakuumpumpenteile KF