5 Critical Die Cast Aluminum Cost Factors

Willkommen auf meinem Blog!

Ich freue mich sehr, dass du hier bist! Bevor wir uns in die Inhalte vertiefen, würde ich mich freuen, wenn du mir auf meinen Social-Media-Plattformen folgst. Dort teile ich zusätzliche Einblicke, vernetze mich mit unserer großartigen Community und halte dich über die neuesten Nachrichten auf dem Laufenden. So bleibst du in Verbindung:

📘 Facebook: Shanghai Leierwo Industriehandel Co., Ltd.

Lassen Sie uns gemeinsam auf diese Reise gehen! Ich hoffe, Sie finden die Inhalte hier nicht nur aufschlussreich, sondern auch inspirierend und wertvoll. Los geht‘s!

Inhaltsverzeichnis

Key Points You’ll Learn in This Article

- Major cost drivers of die cast aluminum production

- How material choice impacts pricing and performance

- Tooling, design complexity, and production volume effects

- Secondary processes and finishing cost breakdown

- Practical cost optimization strategies for buyers

- Real-world examples and data-backed cost ranges

- Frequently asked questions buyers search on Google

Einführung

Die cast aluminum is a popular manufacturing method for high-volume metal parts due to its high precision, excellent surface finish, and strong mechanical properties. However, pricing die cast aluminum components accurately is not as simple as multiplying weight by material price. The real cost depends on multiple factors such as tooling, design complexity, production volume, machining, finishing, and quality control.

If you are a procurement manager or product engineer, understanding these cost drivers helps you:

- Avoid unexpected cost overruns

- Make smarter design decisions

- Compare suppliers more effectively

- Negotiate better quotes

- Optimize product performance without paying extra

According to industry sourcing data, material accounts for about 45–60% of die casting costs, while tooling and machining can make up the remaining portion depending on part complexity.

1. Material and Alloy Choice: The Biggest Cost Driver

Why Material Costs Dominate Die Cast Aluminum Pricing

Material cost is often the largest portion of die cast aluminum expenses because aluminum alloys suitable for die casting are specially formulated for fluidity, strength, and corrosion resistance.

Common Die Cast Aluminum Alloys and Their Cost Differences

Here are the most commonly used die cast aluminum alloys and their typical cost/usage characteristics:

- ADC12

- Widely used for general die cast aluminum parts

- Good fluidity and cost-effectiveness

- A383

- Higher silicon content

- Better corrosion resistance and castability

- Higher cost than ADC12

- A360

- Better ductility and fatigue resistance

- Often used in structural parts

- Higher price range

- A380

- Balanced strength and cost

- Popular for automotive and industrial parts

Material Waste and Recycling

Die casting typically produces 5–10% waste from sprues, runners, and trimming.

However, most of this scrap can be recycled and re-melted, which lowers material cost over time.

Material-related cost list:

- Raw alloy price per kg

- Scrap and recycling ratio

- Material density and weight per part

- Extra material for gating and trimming

- Quality of alloy (impurities affect performance and cost)

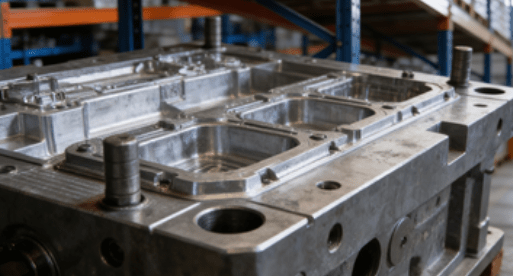

2. Tooling and Mold Costs: The Upfront Investment

Why Tooling Is Expensive for Die Cast Aluminum

Tooling refers to the die or mold used in the casting process. Since die cast aluminum requires high-pressure injection and rapid cooling, molds must be made of hardened steel and engineered to high precision. This makes tooling costly.

Typical Tooling Cost Range

- Simple single-cavity die: $3,000–$10,000

- Complex multi-cavity die: $20,000–$100,000+

- Additional features like slides, ejectors, and cooling channels add cost

Tooling Cost List

- Die material and hardness

- Number of cavities

- Cooling system complexity

- Side actions and undercut mechanisms

- Expected tool life (cycles)

- Maintenance and repair costs

Tooling Cost Amortization

Tooling is a fixed cost, which means the more parts produced, the lower the per-unit cost becomes. This is why die cast aluminum is most cost-effective for Großserienproduktion.

3. Part Design and Complexity: Hidden Cost Drivers

How Design Influences Die Cast Aluminum Costs

The geometry of a part directly impacts production efficiency. Complex shapes require longer cycle times, more advanced dies, and additional finishing processes.

Design complexity list:

- Wall thickness variation

- Undercuts and deep cavities

- Tight tolerances

- Thin ribs and fine details

- Large size or heavy parts

- Complex gating and runner systems

Design for Manufacturability (DFM) Tips

To reduce die cast aluminum costs, apply DFM principles:

- Maintain uniform wall thickness

- Avoid unnecessary undercuts

- Use fillets instead of sharp corners

- Simplify geometry where possible

- Reduce tight tolerance requirements when not necessary

Real-world Example

A part redesigned from 0.8 mm thin walls to 1.5 mm uniform walls can reduce scrap rate, improve filling, and reduce mold wear, resulting in 10–20% lower per-unit cost.

4. Production Volume and Economies of Scale

Why Volume Is Key for Die Cast Aluminum Cost

Die cast aluminum is optimized for mass production. The fixed tooling cost is spread across units, so the cost per part decreases significantly as volume increases.

Volume impact list:

- Small batch (1,000–5,000 units): high per-unit cost

- Medium batch (10,000–50,000 units): moderate per-unit cost

- Large batch (100,000+ units): lowest per-unit cost

Typical Cost Differences by Volume

A 100g die cast aluminum part may cost:

- $1.50 per unit at 1,000 units

- $0.80 per unit at 100,000 units

This is why buyers must plan production volumes early.

5. Secondary Operations and Finishing Costs

Why Secondary Processing Adds Up

Most die cast aluminum parts require additional processing after casting:

- CNC machining (drilling, tapping, milling)

- Surface finishing (anodizing, powder coating, painting)

- Heat treatment or stress relief

- Inspection and testing

Secondary Process Cost List

- Machining time and tool wear

- Surface finish method

- Tolerance and inspection requirements

- Packaging and shipping

- Quality assurance and certification

Common Finishing Options and Costs

| Finish Type | Cost Impact | Benefit | Typische Verwendung |

|---|---|---|---|

| Anodizing | Medium | Corrosion resistance, appearance | Electronics, outdoor parts |

| Powder coating | Medium | Durability, aesthetics | Automotive, consumer goods |

| Painting | Low–Medium | Color and finish | Decorative parts |

| Plating | Hoch | Wear resistance and conductivity | Specialized parts |

Comparative Cost Analysis: Die Casting vs Other Methods

To help buyers make smarter choices, here is a direct comparison:

| Method | Kostenniveau | Volume Suitability | Strength & Precision | Best Use Case |

|---|---|---|---|---|

| Die Cast Aluminum | Medium (high volume) | Hoch | High strength, good precision | Mass production |

| Sandguss | Low–Medium | Low–Medium | Mäßig | Large parts or prototypes |

| CNC-Bearbeitung | Hoch | Low–Medium | Very high precision | Small batch or precision parts |

| Injection Molding (Plastic) | Medium | Hoch | Mäßig | Non-metal parts |

Cost Optimization Tips for Buyers

Reducing the cost of die cast aluminum parts is not just about negotiating material prices. The most effective savings usually come from smart design decisions, proper planning, and a clear understanding of how each cost component works. Below are practical strategies that procurement teams can apply to lower overall expenses without sacrificing quality.

Start with DFM early in the design stage

Design for Manufacturability (DFM) is one of the most powerful ways to reduce die cast aluminum cost. When manufacturing engineers are involved early, they can identify features that will increase tool complexity, cycle time, or scrap rate. For example, parts with uneven wall thickness often suffer from warping and shrinkage, leading to higher reject rates. By designing parts with uniform wall thickness and fewer undercuts, companies can significantly reduce tooling and production issues.

In many real-world projects, early DFM work can cut tooling cost by 10–20% and reduce scrap rate by 15–30%. This not only lowers cost but also shortens lead time.

Choose the simplest alloy that meets requirements

Many buyers automatically choose high-grade alloys thinking they are getting better performance. However, over-specifying material is a common cost trap. For many applications, a standard alloy such as ADC12 or A380 provides sufficient strength and corrosion resistance. Only in high-stress or high-temperature environments is it necessary to move to more expensive alloys like A360.

A practical approach is to start with the lowest-cost alloy that meets the performance requirements, then validate it through testing. If the part fails under load or environmental conditions, upgrade the alloy accordingly. This method prevents unnecessary material cost and ensures the design is optimized for both performance and budget.

Consolidate parts into fewer components

Part consolidation is a proven cost-saving strategy. Multiple small parts require more molds, more assembly steps, and more inventory. By integrating multiple features into one casting, buyers can reduce assembly time, minimize fasteners, and lower the risk of joint failures. In many cases, consolidating 3–4 parts into a single die cast component can reduce total cost by 15–25% and improve product reliability.

Increase batch volume to lower per-unit cost

Die casting is a high-volume manufacturing process. Tooling is a fixed cost, and the more parts produced, the lower the per-unit cost becomes. For example, a part that costs $1.50 per unit at 1,000 pieces may drop to $0.80 per unit at 100,000 pieces. This is why planning production volume early and negotiating volume discounts can deliver significant savings.

If your product is expected to grow in demand, consider ordering larger batches initially or setting up staged production plans. This allows you to lock in lower prices as volume increases.

Request quotes including all secondary operations

Secondary operations are often the hidden cost in die cast aluminum production. Machining, heat treatment, surface finishing, and inspection can add significant expenses if not planned properly. When requesting quotes, procurement teams should ask for a detailed breakdown including:

- CNC-Bearbeitung

- Drilling and tapping

- Surface finishing (anodizing, powder coating, painting)

- Inspection and testing

- Packaging and shipping

A detailed quote helps you compare suppliers objectively and avoid surprises later. It also gives you leverage to negotiate specific items like machining time or surface finish requirements.

Consider standard sizes and features to reduce custom tooling

Custom tooling is expensive, and the more unique the part features, the higher the cost. Using standard wall thickness, draft angles, and rib patterns can reduce tool complexity. Additionally, standardizing mounting holes and features across product families can reduce the need for multiple molds.

In many industries, standardization is a key way to achieve cost efficiency without reducing performance. It also simplifies supplier selection and accelerates time to market.

Negotiate tool life guarantees and maintenance terms

Tool wear is a real cost factor that impacts quality and long-term production stability. When a mold wears out, the defect rate increases and parts may fall out of tolerance. To prevent this, procurement teams should negotiate tool life guarantees and include maintenance terms in the contract. This includes:

- Expected tool life (number of cycles)

- Maintenance schedules

- Repair costs and responsibility

- Quality inspection reports

Having these terms in place ensures consistent quality and prevents unexpected downtime.

Optimize gating and runner design

Gating and runners determine how molten aluminum flows into the mold. Poor design increases waste, increases cycle time, and can cause defects such as porosity or cold shuts. By optimizing the runner system, companies can reduce material waste and improve production efficiency. In some cases, switching to a hot runner system can reduce scrap and improve yield, although it may increase initial tooling cost.

Abschluss

Die cast aluminum cost is influenced by material, tooling, design complexity, volume, and secondary processing. By understanding these cost factors, buyers can make informed decisions and optimize product design for cost-effective manufacturing.

Häufig gestellte Fragen

What factors make die cast aluminum expensive?

High tooling costs, complex part design, and secondary operations are the main cost drivers. Material price also plays a major role.

Ist die cast aluminum cheaper than CNC machining?

For high-volume production, die cast aluminum is typically cheaper. CNC machining is better for low-volume or high-precision parts.

How can I reduce die cast aluminum cost without losing quality?

Use DFM, choose the right alloy, simplify geometry, and increase production volume.

What is the typical lead time for die cast aluminum parts?

Lead time depends on tooling complexity, but generally ranges from 4–12 weeks for new tooling.

How do I get the most accurate quote for die cast aluminum?

Provide CAD files, required tolerances, surface finish, expected volume, and target budget.

Produktkategorien

- Ventilteile

- Wasserpumpenteile

- Lagergehäuseteile

- Druckgussteile

- Pumpenprodukte aus Edelstahl

- Pumpenprodukte aus Gusseisen

- Ventilteile für den Automobilgebrauch

- Autoteile

- Ventilteile für den zivilen Gebrauch

- Vakuumpumpenteile KF