الطباعة ثلاثية الأبعاد

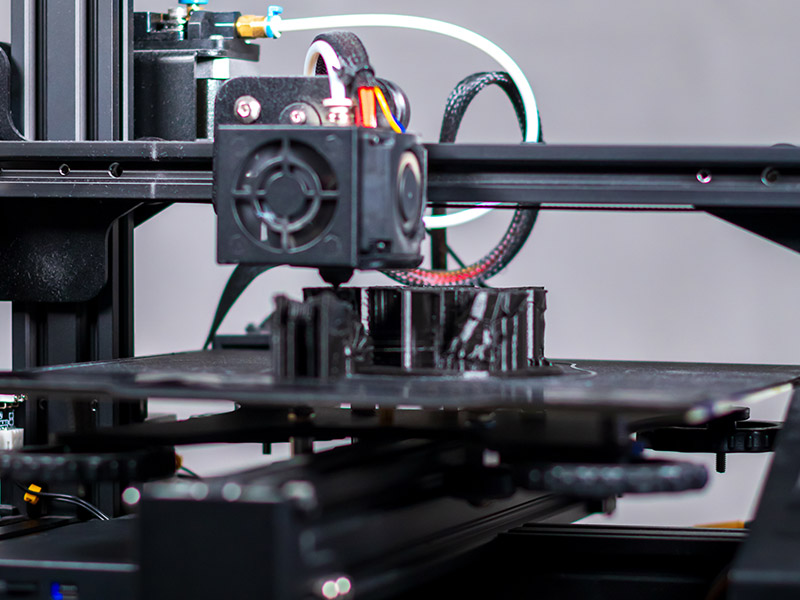

لدينا أكثر من 300 جهاز طباعة ثلاثية الأبعاد، تغطي جميع عمليات إنتاج الطباعة ثلاثية الأبعاد الرئيسية. بفضل المعدات المتطورة وتشكيلة المواد الغنية، نقدم حلول تصنيع مرنة ومتنوعة.

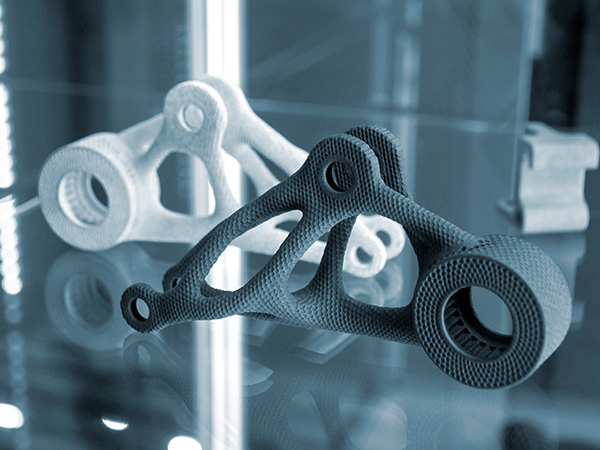

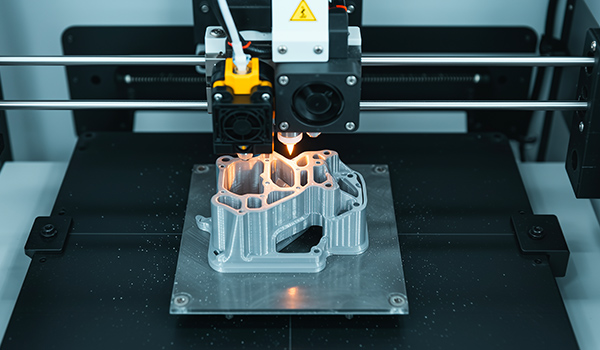

الطباعة ثلاثية الأبعاد, اكتسبت الطباعة ثلاثية الأبعاد، وهي عملية تصنيع مضافة متقدمة، شعبية واسعة لقدرتها على بناء أجزاء معقدة بدقة. وبالمقارنة مع طرق التصنيع الطرحية التقليدية، توفر الطباعة ثلاثية الأبعاد مزايا كبيرة، لا سيما في تحقيق هياكل معقدة وتصميمات شخصية. كما أن دعمها لمجموعة واسعة من المواد، بما في ذلك المعادن والبلاستيك والسيراميك، يجعلها مثالية لإنتاج أجزاء عالية الدقة ومعقدة للغاية.

من خلال عملية الطباعة طبقةً تلو الأخرى، تلتقط الطباعة ثلاثية الأبعاد بدقة حتى أدق تفاصيل التصميم، مما يتيح الحصول على أشكال هندسية معقدة وتفاوتات دقيقة، مما يقلل غالبًا من الحاجة إلى المعالجة اللاحقة. هذا يجعل الطباعة ثلاثية الأبعاد ميزةً كبيرةً في صناعات مثل الفضاء والسيارات والطب، وخاصةً عند إنتاج قطع غيار عالية الدقة ومتينة.

علاوة على ذلك، توفر عملية الطباعة ثلاثية الأبعاد مرونة عالية، تلبي احتياجات الإنتاج بكميات صغيرة والنماذج الأولية. سواءً كان ذلك لتخصيص قطعة واحدة، أو للنماذج الأولية السريعة، أو للإنتاج على نطاق واسع، توفر الطباعة ثلاثية الأبعاد جودة وموثوقية ثابتتين، مما يجعلها الحل الأمثل لإنتاج قطع عالية الأداء مصممة خصيصًا لتلبية احتياجاتكم الخاصة.

من خلال عملية الطباعة طبقةً تلو الأخرى، تلتقط الطباعة ثلاثية الأبعاد بدقة حتى أدق تفاصيل التصميم، مما يتيح الحصول على أشكال هندسية معقدة وتفاوتات دقيقة، مما يقلل غالبًا من الحاجة إلى المعالجة اللاحقة. هذا يجعل الطباعة ثلاثية الأبعاد ميزةً كبيرةً في صناعات مثل الفضاء والسيارات والطب، وخاصةً عند إنتاج قطع غيار عالية الدقة ومتينة.

علاوة على ذلك، توفر عملية الطباعة ثلاثية الأبعاد مرونة عالية، تلبي احتياجات الإنتاج بكميات صغيرة والنماذج الأولية. سواءً كان ذلك لتخصيص قطعة واحدة، أو للنماذج الأولية السريعة، أو للإنتاج على نطاق واسع، توفر الطباعة ثلاثية الأبعاد جودة وموثوقية ثابتتين، مما يجعلها الحل الأمثل لإنتاج قطع عالية الأداء مصممة خصيصًا لتلبية احتياجاتكم الخاصة.

تقنية الطباعة ثلاثية الأبعاد الأساسية لدينا

مجموعة واسعة من المواد والمعالجات السطحية

نقدم مجموعة متنوعة من تقنيات الطباعة ثلاثية الأبعاد، وأحجام الطباعة، والمواد، لضمان إنتاج منتجكم بالكامل باللون والمادة واللمسة النهائية المطلوبة. كما نقدم خدمات طباعة ثلاثية الأبعاد شاملة، تشمل مجموعة واسعة من الألوان والمواد واللمسات النهائية، لضمان تجسيد كل عمل فني في أبهى صوره.

تشمل عمليات معالجة الأسطح المتاحة ما يلي:: الطلاء، الصباغة، النقر، طباعة الشاشة الحريرية، الطحن الناعم، الطحن بالبخار، التلدين، الطحن، الأكسدة، والطلاء الكهربائي.

تشمل عمليات معالجة الأسطح المتاحة ما يلي:: الطلاء، الصباغة، النقر، طباعة الشاشة الحريرية، الطحن الناعم، الطحن بالبخار، التلدين، الطحن، الأكسدة، والطلاء الكهربائي.

مجموعة واسعة من مجالات التطبيق والحالات الناجحة

إن مرونة تقنية الطباعة ثلاثية الأبعاد قادرة على تحويل أي فكرة جامحة إلى حقيقة، مما يساعد منتجك على إكمال الرحلة بنجاح من 1 إلى 100000 وحدة.

صناعة السيارات

إنتاج أجزاء مخصصة حسب الطلب أو إصلاح الأجزاء المتوقفة (على سبيل المثال، إصلاح رأس أسطوانة بورشه كاريرا).

يدعم الإنتاج المرن والذكي، مما يتيح الاستجابة المرنة لفئات المنتجات المتنوعة والدفعات الصغيرة والاحتياجات الشخصية.

يتم استخدامه في تصنيع أجزاء السيارات والتصميم خفيف الوزن والتطبيقات المخصصة وتصنيع قوالب الإطارات.

يلبي المتطلبات البيئية القاسية مثل التشغيل عالي التردد، والعمر الطويل، ومقاومة الماء، ومقاومة التآكل، ومقاومة الحرارة.

يدعم الإنتاج المرن والذكي، مما يتيح الاستجابة المرنة لفئات المنتجات المتنوعة والدفعات الصغيرة والاحتياجات الشخصية.

يتم استخدامه في تصنيع أجزاء السيارات والتصميم خفيف الوزن والتطبيقات المخصصة وتصنيع قوالب الإطارات.

يلبي المتطلبات البيئية القاسية مثل التشغيل عالي التردد، والعمر الطويل، ومقاومة الماء، ومقاومة التآكل، ومقاومة الحرارة.

الروبوتات

ملكنا الطباعة ثلاثية الأبعاد تُسهّل هذه الأنظمة عملية إنشاء النماذج الأولية واختبارها بسرعة، مما يضمن جودةً ووظائفَ شبه نهائية للعينات، مثل مقاومة التآكل ومقاومة الصدمات والدقة. وقد طُبّقت بنجاح لتطوير مكونات أساسية، بما في ذلك أنظمة الدفع تحت الماء.

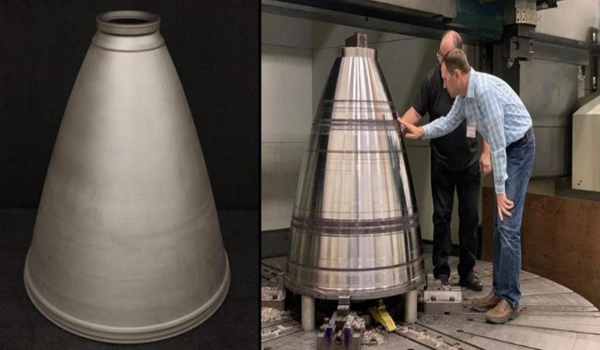

الفضاء الجوي

الطباعة ثلاثية الأبعاد يُستخدم في تصنيع مكونات محركات الصواريخ، مما يُقلل من التعقيد والوزن بفضل مادة 40%، ويُحسّن السلامة والموثوقية، ويُقلل من الإجهاد الحراري. كما يُتيح إنتاج قطع غيار جوية وفضائية واسعة النطاق، مثل خزانات وقود الأقمار الصناعية مقاس 46 بوصة.

الفن والتصميم

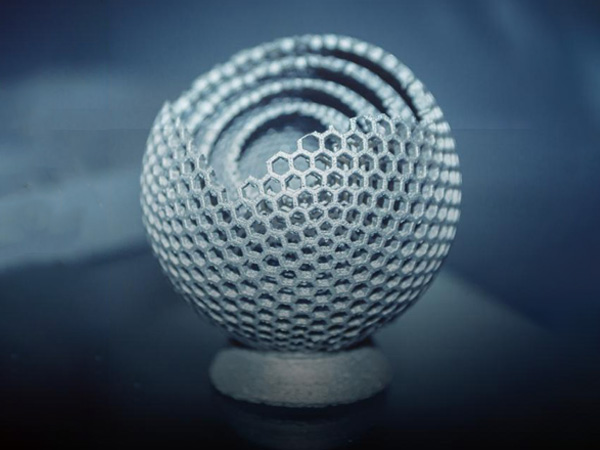

إضفاء الحيوية على المنحوتات والتصميمات الفنية ذات الأشكال الهندسية المعقدة، والتغلب على قيود تقنيات التصنيع الطرحية التقليدية.

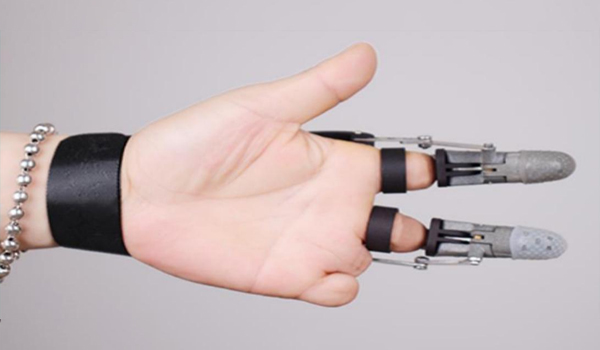

المجال الطبي

يساعد في تصنيع الأجهزة المساعدة مثل أطراف الأصابع، مما يحسن بشكل كبير من كفاءة الإنتاج ويقلل التكاليف.

طائرات بدون طيار

إنتاج أجزاء مثل الأغطية، وحوامل المروحة، والحوامل الداخلية.

النموذج الأولي إلى الإنتاج

توفير خدمات كاملة للعملية من النماذج الأولية إلى الإنتاج الضخم.

اختر مزايانا

نحن ملتزمون بتقديم خدمات الإنتاج الشاملة لمساعدة العملاء على تسريع عمليات تطوير المنتجات وتسريع الوقت اللازم لطرحها في السوق.

عملية الخدمة لدينا

نحن نقدم خدمات الإنتاج الشاملة لتبسيط عملية بدء مشروعك

1.إرسال استفسار

قم بإرسال رسومات CAD وملفات 3D الخاصة بك عبر البريد الإلكتروني مع الإشارة إلى درجة المادة وكمية الطلب واللمسة النهائية للسطح أو التفاصيل الأخرى ذات الصلة.

2. حساب التكلفة

سيقوم فريق الهندسة لدينا بتقييم الرسومات في أقرب وقت ممكن وحساب السعر بناءً على تكلفة الإنتاج الفعلية.

3.بدء الإنتاج

بعد الموافقة على السعر، سيقوم فريق الإنتاج لدينا بإعداد المواد بسرعة وترتيب الإنتاج لضمان التسليم في الوقت المحدد.

4.ترتيب التسليم

بعد اكتمال الإنتاج، سوف نقدم تفاصيل التعبئة والتغليف ونرتب الشحن عن طريق البحر أو الجو، ودعم التسليم في جميع أنحاء العالم.

الالتزام بالجودة والاستدامة

لدينا نظام شامل لمراقبة الجودة يغطي كل خطوة، من الحصول على المواد الخام إلى المعالجة والفحص النهائي. جميع بيانات عملائنا محفوظة بسرية تامة.

نحن ملتزمون بتوفير بيئة معيشية أكثر صحة واستدامة لجميع سكان الكوكب. نبحث ونستكشف ونطبق معايير وممارسات للحد من البصمة الكربونية لعمليات إنتاجنا. نلزم مصانعنا بإعادة تدوير مياه الصرف الصحي والمواد بما يتوافق تمامًا مع اللوائح البيئية المحلية.

نحن ملتزمون بتوفير بيئة معيشية أكثر صحة واستدامة لجميع سكان الكوكب. نبحث ونستكشف ونطبق معايير وممارسات للحد من البصمة الكربونية لعمليات إنتاجنا. نلزم مصانعنا بإعادة تدوير مياه الصرف الصحي والمواد بما يتوافق تمامًا مع اللوائح البيئية المحلية.

شهادات العملاء

“"هناك العديد من المواد للاختيار من بينها"”

لم أكن متأكدًا من المادة الأنسب لمشروع طائرتي المسيرة الجديد، لذا طلبتُ النصيحة من مدير حسابي. قام بتحليلها بدقة وأوصى بأفضل مادة لي. كان برنامج 3DS Pro مفيدًا جدًا، وكانت النتائج ممتازة. شكرًا لك!

ميا

إيطاليا، طائرات بدون طيار

“"إنهم يقومون بعمل عظيم"”

كان لمشروعنا X7 العديد من المتطلبات التي تطلبت اهتمامًا خاصًا من الشركة المصنعة. وقد أخذوا هذه المتطلبات على محمل الجد، وتم تسليم المشروع على أكمل وجه.

نيك

المملكة المتحدة، الإلكترونيات الاستهلاكية

“"نحن مضغوطون بالوقت"”

عندما تواصلنا مع 3DSPRO، كان الجميع على وشك السفر في إجازة، وكان جدولنا ضيقًا. تمكّنوا من إنتاج المنتج لنا في الوقت المحدد. أحسنتم يا رفاق!

علامة

ألمانيا، السيارات

الأسئلة الشائعة

س1. هل أنتم شركة تجارية أم شركة مصنعة؟

س2. هل يمكنك تقديم عرض أسعار بناءً على رسومات ثلاثية الأبعاد؟

س3. كيف تتعاملون مع طلبات عروض الأسعار (RFQs)؟

س4. ما هي مدة التسليم النموذجية لديكم؟

س5. هل تقدمون عينات؟ وهل هي مجانية؟

س6. ما هي طرق الدفع التي تقبلونها؟

س7. كيف تضمن مراقبة الجودة؟

س8. هل منتجاتكم تأتي مع ضمان؟

س9. كيف تنظر إلى علاقتك مع العملاء؟