لماذا تتجه صناعة صب المعادن إلى تقنيات الدقة

جدول المحتويات

مقدمة

ال metal casting industry has experienced significant advancements over the past few decades. While traditional metal casting methods have long been the standard, there is an ongoing shift towards precision techniques that are transforming how manufacturers approach metal casting. Precision casting refers to the use of highly accurate methods to produce metal parts with tight tolerances and high-quality surfaces. This blog will explore why the metal casting industry is transitioning to precision casting techniques, highlighting the benefits, key industries driving this change, and the technologies making it possible.

The Role of Precision Techniques in Reducing Metal Casting Defects

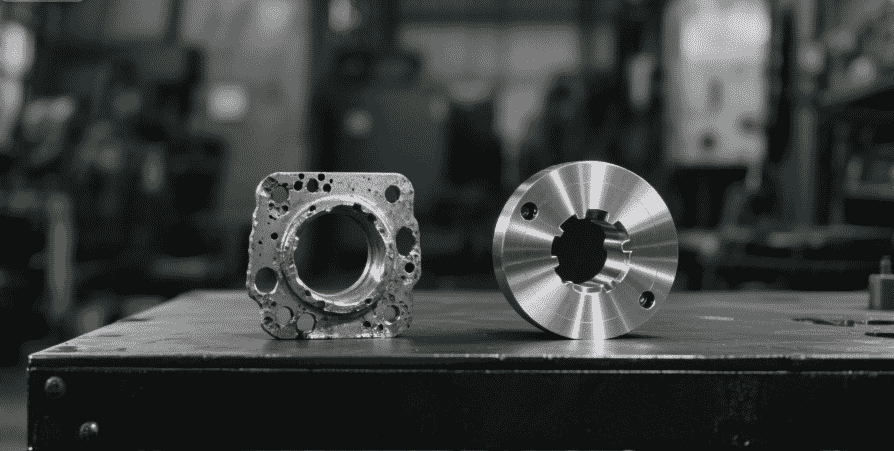

One of the primary reasons the metal casting industry is shifting to precision techniques is the ability to significantly reduce casting defects. Traditional casting methods often struggle with issues such as porosity, dimensional inaccuracies, and surface roughness. These imperfections not only compromise the quality of the final product but can also lead to significant costs due to rework, material waste, and product rejection.

المسامية, which results from trapped gas or moisture during casting, can weaken the structural integrity of parts, making them prone to cracks or failure under stress. Similarly, dimensional inaccuracies lead to parts that do not fit as intended, requiring expensive rework and wasting valuable time. Surface roughness can make parts unsuitable for functional or aesthetic purposes, forcing manufacturers to spend additional time on post-casting processes like machining or polishing.

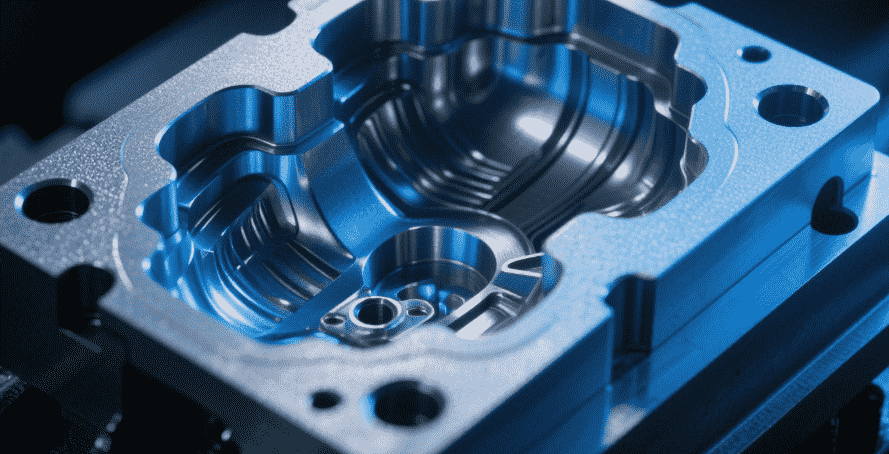

Precision casting minimizes these defects by using advanced technologies like computer-aided design (CAD), تصنيع باستخدام الحاسب الآلي، و high-precision molding techniques. These innovations ensure that parts are produced with greater accuracy, reducing the need for post-casting machining, improving the overall quality of the final product, and streamlining the manufacturing process. This shift towards precision casting offers a more reliable, cost-effective solution, especially for high-performance applications that demand superior quality.

How Precision Metal Casting Enhances Product Quality and Performance

In the metal casting industry, product quality and performance are key to maintaining customer satisfaction and securing long-term contracts. Precision casting techniques allow manufacturers to create parts with exacting dimensions, making it possible to meet the tightest tolerances. Whether it’s producing aerospace components, automotive parts, or medical devices, the need for precise and high-performance parts is increasing across various industries.

Precision casting ensures that parts not only meet dimensional requirements but also have improved mechanical properties, including greater strength, durability, and corrosion resistance. This is crucial for industries like السيارات, aerospace، و medical devices, where component failure can result in catastrophic consequences.

For instance, the automotive sector benefits from precision casting because it enables the production of lightweight, durable, and high-strength parts that contribute to the vehicle’s overall performance, fuel efficiency, and safety. Similarly, precision casting is crucial in the aerospace industry, where the performance of each component can directly impact the efficiency and safety of the aircraft.

Key Industries Adopting Precision Techniques in Metal Casting

Precision casting is increasingly being adopted by several industries looking to enhance their metal casting processes. These industries benefit from the ability to produce high-quality, consistent parts with minimal defects and reduced need for post-casting processing. Here are some key industries driving the shift toward precision casting:

- الفضاء الجوي: Precision casting ensures components used in aircraft engines, fuselages, and landing gears meet the strict quality standards required for safety and performance. Turbine blades و engine components, for instance, require precise casting to ensure their efficiency and durability under extreme conditions.

- السيارات: Precision casting helps manufacturers produce lightweight, strong, and durable parts, enhancing vehicle performance, fuel efficiency, and safety. The production of engine blocks, brake components، و suspension parts benefits from the enhanced material properties achieved through precision casting.

- الأجهزة الطبية: The medical field requires parts with exacting quality and functionality standards. Precision casting is used to manufacture implants, surgical instruments, and other critical components. For example, titanium implants are precision-cast to ensure biocompatibility and durability in the human body.

- Energy: The energy sector relies heavily on precision casting for the production of parts that must endure extreme temperatures and pressures. Turbine blades, أوعية الضغط، و engine components produced with precision casting offer superior strength and reliability, essential for efficient energy generation.

- صب الصمامات: Precision valve casting is crucial in industries where controlling the flow of liquids and gases under extreme pressure and temperature is necessary. Valves used in oil and gas pipelines, water treatment plants, and industrial systems need to withstand high pressure, corrosion, and wear.

- Example: Gate valves, used in chemical plants, are cast with high precision to ensure they can withstand corrosive materials while providing secure sealing under high pressure. The accuracy of the casting process ensures that the valves perform reliably in critical applications.

- Pump Body Casting: Precision casting is used to manufacture pump bodies that are strong enough to handle high-pressure environments while maintaining efficiency. These parts must be precisely cast to ensure proper functioning without leakages or failure under constant operation.

- Example: A centrifugal pump used in water treatment or chemical industries is precision-cast to meet specific performance standards. The pump body needs to be highly durable, resistant to corrosion, and capable of withstanding high-temperature conditions, which precision casting ensures.

- الصب العام: Precision casting is used in many other industries for a variety of applications that require parts with specific properties and performance characteristics. General casting techniques are applicable in sectors like بناء, الآلات الثقيلة، و consumer goods, where quality, durability, and strength are critical for performance.

- Example: Construction equipment components, such as machine frames و gearboxes, benefit from precision casting due to the need for parts that can withstand heavy mechanical loads and exposure to harsh outdoor environments.

The Impact of Precision Techniques on Metal Casting Lead Times

The use of precision techniques in the metal casting industry also significantly impacts lead times. Traditional casting methods can often be slow, particularly when a high level of post-casting machining is required. With precision casting, manufacturers can reduce the need for additional finishing operations by producing parts that are closer to the final specifications directly out of the mold. This not only speeds up the production process but also reduces the overall cost by minimizing the amount of time and resources spent on rework.

For example, precision casting can reduce the time spent on machining by up to 40%, which allows companies to meet tighter deadlines and increase throughput. Additionally, reducing post-processing time directly translates to cost savings, making the entire manufacturing process more efficient and affordable.

Why Precision Metal Casting is a Game-Changer for High-Performance Parts

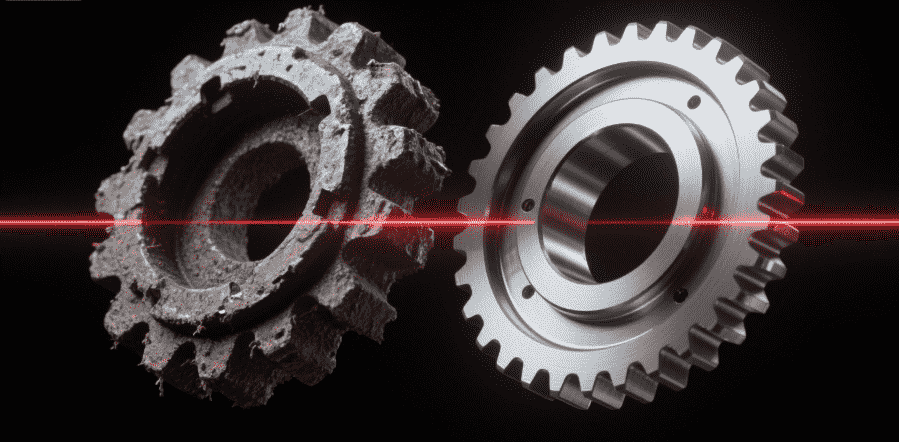

Precision casting is especially crucial for producing high-performance parts in industries where the demands for strength, reliability, and longevity are critical. High-performance parts, such as engine components أو aerospace parts, must be able to withstand extreme conditions, including high temperatures, pressure, and mechanical stress. Traditional casting methods often fall short in meeting these demanding requirements.

The precision casting process allows manufacturers to use specialized materials and techniques that result in parts with improved mechanical properties, such as:

- Greater tensile strength: Ideal for components exposed to high levels of stress and force.

- Better resistance to corrosion: Crucial for parts used in corrosive environments like marine or oil and gas industries.

- Higher durability: Ensures that parts maintain their integrity over time, even in challenging operational environments.

This makes precision casting a game-changer for producing high-performance parts that can operate in the most challenging environments.

The Growing Demand for Precision Casting in the Oil and Gas Industry

ال oil and gas industry is another sector that has seen an increased demand for precision casting. This industry requires parts that can withstand extreme conditions, such as high-pressure environments and exposure to corrosive substances. Precision casting techniques allow manufacturers to create parts like valves, مضخات، و أوعية الضغط that meet the stringent requirements of the oil and gas sector.

These parts must be able to endure harsh conditions such as:

- High pressures: Essential for parts like pressure relief valves that regulate pressure within equipment.

- High temperatures: For components like engine blocks أو piping exposed to extreme heat.

- Corrosive environments: Critical for parts used in subsea applications where exposure to saltwater and other corrosive materials is inevitable.

With precision casting, these parts are produced with greater consistency, reducing the risk of failure and downtime. The increased durability and reliability offered by precision casting also contribute to the overall safety and efficiency of oil and gas operations.

How Precision Techniques Improve Cast Part Performance in Harsh Environments

Precision casting plays a critical role in ensuring that parts perform well in harsh environments. For example, in industries such as mining, energy, and aerospace, components are often exposed to high stress, temperature fluctuations, and corrosive materials. Precision casting techniques help improve the mechanical properties of these parts, making them more resistant to wear and tear, fatigue, and corrosion.

With the precision casting process, parts are produced with a high level of control over material composition and structure, ensuring that they can withstand the most demanding environments without compromising performance or safety.

How Precision Casting Contributes to High-Quality Casting Surfaces

Another advantage of precision casting is its ability to produce high-quality casting surfaces. In traditional casting methods, the surface finish of the part often requires additional machining, which adds to the overall cost and production time. However, precision casting techniques can produce parts with smoother surfaces and better dimensional accuracy directly from the mold, reducing the need for post-processing.

This is especially important for industries where aesthetics or functional surfaces play a significant role, such as in the production of consumer electronics or high-end machinery components. Precision casting offers a more efficient and cost-effective way to achieve high-quality surfaces without additional work.

Comparison of Precision Casting vs. Traditional Metal Casting

| ميزة | Precision Casting | Traditional Casting |

|---|---|---|

| دقة الأبعاد | High precision with tight tolerances | Moderate accuracy, often requires rework |

| تشطيب السطح | Smooth surfaces with minimal post-processing | Rough surfaces requiring finishing |

| مهلة | Reduced due to less post-casting work | Longer due to additional machining |

| Material Utilization | High material efficiency, less waste | Higher material waste and scrap |

| Cost for High-Volume Production | Generally higher initial cost, but cost-effective for complex parts | Lower initial cost but higher long-term costs |

| Industries Benefiting | Aerospace, Automotive, Medical, Oil & Gas | General manufacturing, less complex parts |

خاتمة

ال metal casting industry‘s shift towards precision techniques is driven by the need for higher-quality, more reliable parts that meet the demands of modern manufacturing. Precision casting provides a solution to many of the challenges faced by traditional casting methods, such as reducing defects, improving product quality, and lowering long-term production costs. As industries such as aerospace, automotive, and medical devices continue to demand more advanced and reliable components, precision casting will undoubtedly play an increasingly important role in shaping the future of metal casting.

الأسئلة الشائعة

What is precision casting?

Precision casting refers to a metal casting process that produces parts with high dimensional accuracy and smooth surface finishes, using advanced techniques such as CAD and CNC machining.

Why is precision casting important for the metal casting industry?

Precision casting reduces defects, improves product quality, enhances part performance, and speeds up lead times, making it ideal for industries that require high-performance parts.

What industries benefit most from precision casting?

Key industries that benefit from precision casting include aerospace, automotive, medical devices, energy, and oil & gas.

How does precision casting reduce manufacturing costs?

Precision casting reduces the need for post-casting machining, which helps lower material waste, production time, and rework, ultimately leading to cost savings.

What materials are typically used in precision casting?

Common materials used in precision casting include stainless steel, aluminum, titanium, and various alloys, depending on the specific requirements of the part being produced.

What are the main advantages of precision casting over traditional casting methods?

Precision casting offers several advantages, including higher dimensional accuracy, smoother surface finishes, reduced post-processing requirements, and the ability to cast more complex shapes. These benefits make it ideal for high-performance and critical applications.

How does precision casting improve part strength and durability?

Precision casting techniques allow manufacturers to carefully control material composition and microstructure during the casting process. This results in parts with improved tensile strength, fatigue resistance, and durability, making them suitable for harsh environments.

How does precision casting contribute to sustainability in manufacturing?

Precision casting contributes to sustainability by reducing material waste and improving energy efficiency. The process produces high-quality parts with fewer defects, meaning less rework and material scrap, which in turn reduces the environmental impact of manufacturing operations.

ابقى على اتصال معنا

شكرًا لقراءتكم! نأمل أن تكون هذه المدونة قد زودتكم بمعلومات قيّمة وإلهام حول أسقف الألواح الصوتية. إذا أعجبكم المحتوى وترغبون في البقاء على اطلاع بأحدث الصيحات والنصائح والتحديثات من وراء الكواليس، يسعدنا التواصل معكم عبر وسائل التواصل الاجتماعي.

📘 تابعونا على الفيسبوك: شركة شنغهاي لييروو الصناعية التجارية المحدودة

انضم إلى مجتمعنا المتنامي حيث نشارك نصائح الخبراء وتسليط الضوء على المنتجات والمناقشات التفاعلية مع المحترفين وعشاق التصميم من جميع أنحاء العالم.

دعونا نواصل المحادثة - نراكم هناك!

فئات المنتجات

- أجزاء الصمامات

- أجزاء مضخة المياه

- أجزاء صندوق المحمل

- أجزاء الصب بالقالب

- منتجات مضخات الفولاذ المقاوم للصدأ

- منتجات مضخات الحديد الزهر

- قطع غيار الصمامات لاستخدام السيارات

- قطع غيار السيارات

- أجزاء الصمامات للاستخدام المدني

- قطع غيار مضخة التفريغ KF