شرح عملية صب الاستثمار في الفولاذ: 8 مراحل حرجة في الإنتاج

جدول المحتويات

مقدمة

Steel investment casting is an advanced manufacturing process that involves creating highly precise and complex metal parts by molding molten steel into a particular shape. This method has been extensively used in industries such as aerospace, automotive, and medical equipment, where precision, strength, and intricate designs are required. In this blog, we will break down the steel investment casting process into 8 critical phases, shedding light on the essential steps involved. Additionally, we will explore some common questions related to investment-cast stainless steel and its applications.

ما هو فريق الاستثمار الفولاذ المقاوم للصدأ?

Investment casting, also known as the “lost-wax” casting process, is a metal-forming technique that uses a wax pattern to create a mold. The wax pattern is an exact replica of the final steel part and is made using a specialized injection-molding technique. The wax must be highly detailed and precise, as it forms the core shape of the final product. The quality of the wax pattern directly influences the accuracy and quality of the final casting.

Investment cast stainless steel refers to stainless steel components manufactured using this casting process. These castings are known for their high precision and intricate designs, making them ideal for applications that require both strength and a high level of detail, such as turbine blades, automotive parts, or medical devices.

Can Stainless Steel Be فريق الاستثمار?

Yes, stainless steel can be investment cast. In fact, investment casting is particularly well-suited for stainless steel because it allows for precise control over the shape, dimensions, and surface finish of the final product. The process can accommodate complex geometries that would be difficult or impossible to achieve with other casting methods, such as sand casting. Stainless steel alloys, including 316 stainless steel, are commonly used for investment casting due to their excellent corrosion resistance and high-temperature performance.

8 Critical Phases of Steel الاستثمار في الصب

Phase 1: Wax Pattern Creation – Where the Magic Begins

What is it?

The first step in the process involves creating a wax pattern that perfectly matches the final steel part. This is the heart of investment casting, and it all begins with a highly detailed, precise wax replica of the part you’re aiming to create.

Why it’s important:

The wax pattern is crucial because its accuracy directly impacts the final product. The more precise the wax, the better the final steel casting will be.

Key Steps in Wax Pattern Creation:

- Injection Molding: Wax is injected into a mold to create the pattern.

- Detailing: Every intricate detail of the part, like tiny holes or complex curves, must be captured accurately.

- تبريد: The wax cools and solidifies into the desired shape.

Fun Fact: Did you know that a tiny 1mm difference in the wax pattern could result in a noticeable defect in the final casting? Precision is everything here!

Phase 2: Shell Building – Strength for the Mold

What is it?

Once the wax pattern is ready, it’s coated with layers of heat-resistant ceramic material, forming the “shell.” This shell will hold the molten metal and shape it into the final part.

Why it’s important:

The shell is what gives your mold strength and stability. Without a solid shell, the mold might break during the pouring process, resulting in defects.

How it works:

- Layering: Ceramic material is applied in multiple layers.

- Drying Time: Each layer is allowed to dry and harden before adding the next.

- Final Strength: The shell becomes rock-solid and ready to hold molten metal.

Pro Tip: The thickness of the shell is critical for the strength of the mold. Too thick, and you risk cracking; too thin, and it may not be durable enough.

Phase 3: The Lost Wax Process – A Critical Moment

What is it?

This is where the magic happens! The wax pattern is removed in a process called lost wax. This is done by heating the mold in a furnace, causing the wax to melt and drip away, leaving an empty cavity behind.

Why it’s important:

ال lost wax step is the reason why this process is called “investment casting.” By removing the wax, you are left with a mold that will later be filled with molten metal.

Lost Wax Process:

- Heating the Mold: The mold is carefully heated to melt the wax.

- Wax Removal: The wax drains away, leaving behind a perfect cavity for the molten steel.

- Preparation for Steel: After wax removal, the mold is ready for the next phase.

Fun Fact: The term “lost wax” originates from the fact that the wax is lost forever, but the mold remains.

Phase 4: Dewaxing – Ensuring Perfection

What is it?

After the wax is removed, dewaxing ensures that any remaining traces of wax are fully eliminated from the mold.

Why it’s important:

If any wax residues are left behind, they can contaminate the mold and cause defects in the final casting.

Dewaxing Process:

- Furnace Heating: The mold is heated again to ensure that no wax is left behind.

- Thorough Inspection: The mold is inspected to make sure it’s completely clear of wax.

Pro Tip: Thorough dewaxing ensures there are no contaminants that could lead to internal flaws, such as cracks or porosity, in the casting.

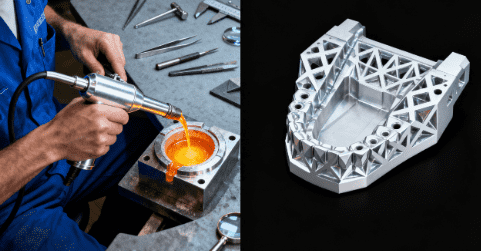

Phase 5: Pouring the Steel – The Heart of the Process

What is it?

Now, molten steel (often alloyed for desired properties like corrosion resistance) is carefully poured into the mold cavity.

Why it’s important:

The pouring process directly affects the final quality of the casting. Molten steel must be poured at the right temperature and at the right speed to avoid defects.

Key Points:

- Temperature Control: Steel must be at the right temperature to ensure it flows smoothly into all parts of the mold.

- Precision Pouring: The steel is poured into the mold at a controlled rate to prevent turbulence or air bubbles.

Fun Fact: Steel is poured at a temperature of around 1,500°C (2,732°F)—hot enough to melt metal, but too hot for humans to even approach!

Phase 6: Cooling and Solidification – Let it Harden

What is it?

Once the steel is poured into the mold, it must cool and solidify to take on the shape of the part.

Why it’s important:

The cooling rate affects the strength and hardness of the steel. Cooling too quickly can cause cracks; cooling too slowly can result in defects in the metal’s structure.

Cooling Process:

- Slow and Steady: The steel is cooled at a controlled rate.

- Metal Properties: The cooling rate determines the mechanical properties of the final steel part.

Pro Tip: Controlled cooling prevents issues like warping, shrinking, or internal stresses.

Phase 7: Shell Removal and Cleaning – Time to Reveal

What is it?

Once the steel has cooled and solidified, the shell is removed to reveal the finished casting.

Why it’s important:

The shell removal and cleaning process is crucial for removing excess materials and ensuring the steel part is clean and defect-free.

Steps:

- Breaking the Shell: The shell is carefully removed, often using mechanical methods.

- تنظيف: The part is cleaned to remove any remaining shell fragments, sand, or debris.

Fun Fact: The clean-up phase is where the intricate details of the steel part really start to shine!

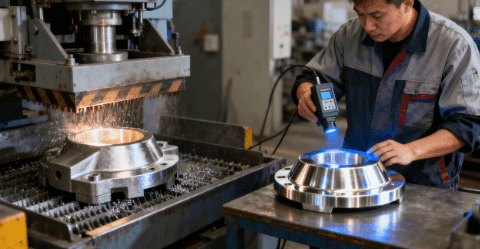

Phase 8: Final Inspection and Quality Control – A Thorough Check

What is it?

After the part is cleaned, it undergoes a thorough inspection to ensure it meets all specifications.

Why it’s important:

This is the final step in ensuring the steel investment casting meets quality standards. Every casting must be checked for dimensions, surface finish, and internal defects.

Inspection Process:

- التفتيش البصري: Check for surface defects like cracks, porosity, or sand inclusions.

- Advanced Testing: Techniques such as X-ray or ultrasonic testing are often used to detect internal defects.

- Dimensions Check: Ensure the part meets precise measurements.

Pro Tip: A final inspection is essential before the part is shipped out for use in critical applications.

Can Investment-Cast 316 Stainless Steel Be Welded to Stainless Pipe?

Yes, investment-cast 316 stainless steel can generally be welded to stainless steel pipes. However, welding these materials together requires careful consideration of a variety of factors, especially given the unique properties of investment-cast 316 stainless steel compared to other types of stainless steel. The steel investment casting process results in a distinct microstructure that can pose challenges when it comes to welding, so understanding these challenges and addressing them properly is crucial for achieving a strong and reliable weld.

Why Welding Investment-Cast 316 الفولاذ المقاوم للصدأ to Stainless Pipe Can Be Tricky

Investment casting is a process that involves creating a mold from a wax pattern, which is then coated with a ceramic shell. After the wax is melted away, molten metal is poured into the mold to form the final steel part. This method results in a fine, detailed finish, but it also creates a cast steel structure with a grain and microstructure that can differ significantly from that of a forged or rolled material, such as a stainless steel pipe.

The microstructure of investment-cast 316 stainless steel often contains a high degree of casting porosity and microsegregation. These can affect its strength and make it more prone to defects during welding, such as cracking or insufficient fusion between the cast steel and the pipe.

Challenges to Consider When Welding Steel الصب الاستثماري to Stainless Pipe

- Microstructure Differences:

- Investment-cast 316 stainless steel typically has a more brittle microstructure than forged or welded stainless steel, meaning it can be more susceptible to stress, particularly when heat is applied during welding.

- The rapid cooling and solidification of molten metal during casting create a more uneven distribution of alloying elements, which could affect its weldability.

- Heat Treatment Requirements:

- To minimize the risk of cracking or other welding defects, pre-welding heat treatments might be necessary. These treatments relieve internal stresses within the cast steel and help to align the microstructure more closely with that of the pipe.

- Post-weld heat treatment is also often required to ensure that the welded joint is properly stress-relieved, and to avoid distortion or thermal cracking.

- Porosity and Surface Defects:

- Investment-cast 316 stainless steel may contain porosity, especially in areas where the wax pattern is more intricate. These voids can trap gases during welding, leading to gas pockets or weak spots in the final weld.

- Ensuring the surface is clean and free from contamination is essential, as any debris or leftover shell material can cause poor weld quality.

- Filler Material and Welding Technique:

- اختيار الصحيح filler material is critical for creating a strong weld between investment-cast 316 stainless steel and stainless pipe. The filler metal must match the base material’s composition to ensure optimal corrosion resistance and strength in the weld joint.

- Welding techniques such as TIG (Tungsten Inert Gas) welding or MIG (Metal Inert Gas) welding are often preferred for their precision and control. Using appropriate heat settings and slow welding speeds can help reduce the risk of introducing defects.

Key Tips for Successful Welding of Investment-Cast 316 Stainless Steel to Stainless Pipe

- Consult an Experienced Welder:

اللحام steel investment castings requires advanced skill and precision. An experienced welder who understands the challenges associated with casting materials will be better able to handle the complexities of the process. - Preheat the Castings:

Preheating the investment-cast 316 stainless steel part can help reduce thermal stress during the welding process. It helps prevent cracking and promotes a more uniform heat distribution throughout the weld joint. - Control the Cooling Rate:

Cooling too quickly can lead to thermal shock, which increases the risk of cracks. Slow and controlled cooling after welding helps ensure the integrity of the weld and prevents distortion or fractures in the cast material. - Perform a Thorough Inspection:

After the welding process, it’s critical to inspect the joint for any visible defects, such as cracks, porosity, or insufficient penetration. Advanced inspection techniques like X-ray or ultrasonic testing can help detect internal issues that may not be visible to the naked eye.

Table: Comparison of Common Stainless Steel Alloys for الاستثمار في الصب

| Stainless Steel Alloy | مقاومة التآكل | Tensile Strength (MPa) | التطبيقات |

|---|---|---|---|

| الفولاذ المقاوم للصدأ 316 | ممتاز | 515 | Marine, chemical processing, medical devices |

| 304 Stainless Steel | جيد | 520 | Food processing, architecture, heat exchangers |

| 17-4 PH Stainless Steel | جيد جدًا | 930 | Aerospace, valves, pumps |

| 2205 Duplex Stainless Steel | ممتاز | 650 | Oil & gas, petrochemical, structural parts |

خاتمة

Steel investment casting is a highly effective method for producing complex, high-precision steel components. The eight critical phases—from the creation of the wax pattern to the final inspection—ensure that every part meets the necessary specifications for strength, precision, and quality. This process is especially beneficial when working with stainless steel alloys, such as 316 stainless steel, for industries that demand both detail and durability.

Choosing the right materials and understanding the investment casting process are essential to achieving the best results. By following the correct procedures at each phase of production, manufacturers can create steel parts that meet the most stringent requirements for performance and quality.

الأسئلة الشائعة

1. What are the main benefits of steel الصب الاستثماري over other methods?

Answer: Steel investment casting offers superior precision, the ability to cast complex shapes, and a high-quality surface finish, which makes it ideal for industries like aerospace, automotive, and medical devices.

2. Can I use any type of الفولاذ المقاوم للصدأ ل الصب الاستثماري?

Answer: While various types of stainless steel can be used for investment casting, the most commonly used alloys are 316 stainless steel for its excellent corrosion resistance and 304 stainless steel for general-purpose applications.

3. How do I determine which الفولاذ المقاوم للصدأ alloy is best for my project?

Answer: The best stainless steel alloy depends on your specific requirements, such as corrosion resistance, strength, and temperature performance. For harsh environments, 316 stainless steel is often preferred.

4. Can الصب الاستثماري be used for large-scale production?

Answer: Yes, steel investment casting is suitable for both small and large-scale production runs. It is highly efficient for producing complex parts in a consistent and cost-effective manner.

5. What are some common defects in الصب الاستثماري, and how can they be avoided?

Answer: Common defects include porosity, cracks, and surface roughness. These can be avoided by carefully controlling the mold preparation, pouring temperature, cooling rate, and performing quality inspections during and after production.

ابقى على اتصال معنا

شكرًا لقراءتكم! نأمل أن تكون هذه المدونة قد زودتكم بمعلومات قيّمة وإلهام حول أسقف الألواح الصوتية. إذا أعجبكم المحتوى وترغبون في البقاء على اطلاع بأحدث الصيحات والنصائح والتحديثات من وراء الكواليس، يسعدنا التواصل معكم عبر وسائل التواصل الاجتماعي.

📘 تابعونا على الفيسبوك: شركة شنغهاي لييروو الصناعية التجارية المحدودة

انضم إلى مجتمعنا المتنامي حيث نشارك نصائح الخبراء وتسليط الضوء على المنتجات والمناقشات التفاعلية مع المحترفين وعشاق التصميم من جميع أنحاء العالم.

دعونا نواصل المحادثة - نراكم هناك!

فئات المنتجات

- أجزاء الصمامات

- أجزاء مضخة المياه

- أجزاء صندوق المحمل

- أجزاء الصب بالقالب

- منتجات مضخات الفولاذ المقاوم للصدأ

- منتجات مضخات الحديد الزهر

- قطع غيار الصمامات لاستخدام السيارات

- قطع غيار السيارات

- أجزاء الصمامات للاستخدام المدني

- قطع غيار مضخة التفريغ KF