8 مزايا بارزة للاستثمار في الأجزاء المعقدة

جدول المحتويات

مقدمة

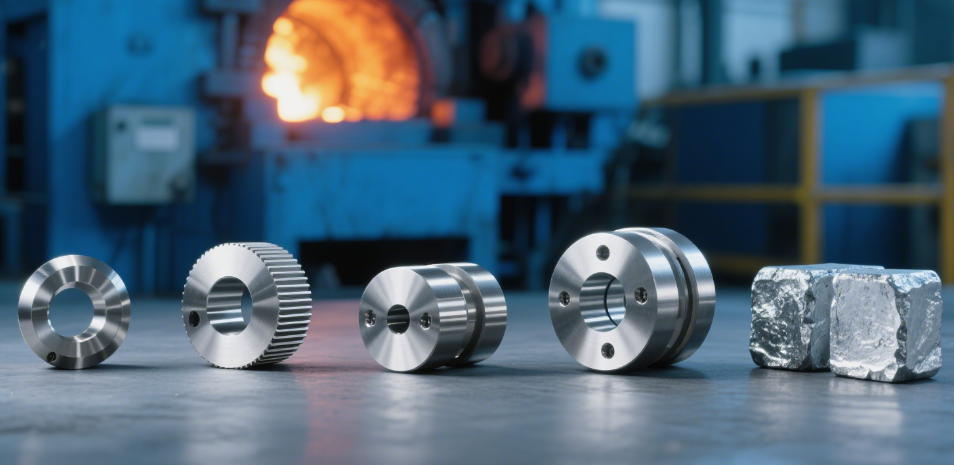

Investment casting, also known as precision casting or lost-wax casting, is a sophisticated manufacturing process renowned for producing intricate and high-precision metal components. This method is particularly advantageous for industries requiring complex geometries, tight tolerances, and superior surface finishes. By utilizing a wax pattern that is coated with a ceramic shell, molten metal is poured into the mold to create the desired part. The versatility of investment casting makes it ideal for producing components in sectors such as aerospace, automotive, medical, and machinery manufacturing.

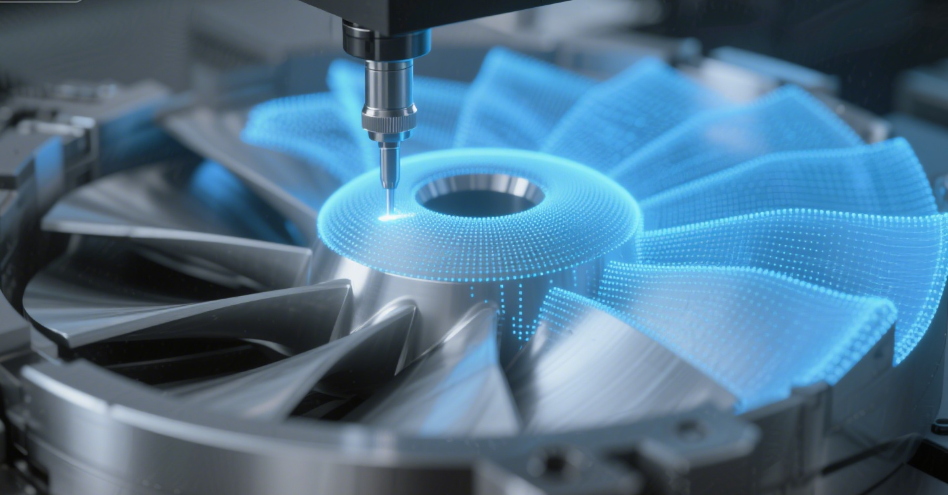

1. Exceptional Precision and Dimensional Accuracy

One of the main advantages of this precision casting process is its ability to produce parts with outstanding accuracy and dimensional consistency. Tolerances can be as tight as ±0.005 inches per inch, ensuring that every component conforms to strict specifications. Such precision reduces the need for extensive post-processing and machining, saving time and lowering production costs.

Furthermore, the accuracy achieved ensures that critical parts—such as aerospace turbine blades, automotive engine components, and medical implants—fit perfectly within their assemblies. By faithfully replicating wax patterns in the final metal pieces, designers can incorporate complex features that would be challenging or even impossible to achieve with traditional casting or machining methods. This high level of fidelity enhances both performance and reliability, particularly in industries where safety and precision are paramount.

2. Capability to Produce Complex Geometries

This casting technique excels at creating components with intricate shapes and fine details that are difficult to produce using conventional methods. The use of wax patterns allows for undercuts, thin walls, internal channels, and lattice structures to be formed in a single step. Such flexibility simplifies design and assembly processes, making it especially valuable for applications requiring structural optimization, weight reduction, or performance efficiency.

For example, aerospace components like turbine blades, combustion chamber elements, and complex ducting systems demand geometries that optimize airflow while minimizing material use. Similarly, surgical instruments and orthopedic implants in the medical sector benefit from complex contours that improve functionality and patient outcomes. By enabling such intricate designs in one step, this process also reduces the number of separate parts needed in an assembly, streamlining production and cutting down assembly labor.

3. Superior Surface Finish Quality

Components produced through this precision method often feature exceptionally smooth surfaces, achieving surface roughness values of 125 RMS or better. This high-quality finish reduces or even eliminates the need for additional machining or polishing, which can save both time and cost.

A fine surface finish is critical not only for appearance but also for functional performance. Medical instruments and implants, for instance, require surfaces that minimize bacterial adhesion and are easy to sterilize. In aerospace and automotive applications, smooth surfaces help reduce friction, improve aerodynamics, and enhance mechanical efficiency. Producing parts with excellent surface quality directly from the mold allows manufacturers to skip many secondary finishing steps without compromising performance.

4. Wide Material Compatibility

Investment casting supports a broad range of metal alloys, including stainless steel, carbon steel, aluminum alloys, nickel-based superalloys, and copper-based alloys. This versatility enables manufacturers to select the optimal material for each application, balancing factors such as strength, corrosion resistance, thermal stability, and wear resistance.

For instance, aerospace components often require superalloys capable of withstanding extremely high temperatures and mechanical stresses, while medical implants rely on biocompatible stainless steels to ensure safety and long-term performance. Similarly, copper and aluminum alloys are frequently used in automotive and electrical applications due to their excellent conductivity and lightweight properties. The wide material compatibility of investment casting allows engineers to meet demanding application requirements without compromising design complexity or performance.

5. Reduced Need for Secondary Machining

Thanks to its near-net-shape capability, this casting process minimizes material waste and reduces reliance on secondary machining. Parts are produced with high precision, often eliminating additional operations like milling, turning, or grinding.

This efficiency saves both time and cost while supporting more sustainable manufacturing practices. For example, in high-volume automotive production, reducing secondary machining can save thousands of labor hours and significant amounts of raw material each year. Moreover, near-net-shape production decreases energy consumption, lowering the environmental footprint without compromising the quality of the final parts.

6. Scalability for Both Small and Large Production Runs

Investment casting is highly adaptable, making it suitable for both small-batch prototyping and large-scale production runs. Whether producing a limited number of prototypes for design validation or thousands of complex parts for full-scale production, investment casting can be efficiently scaled to meet production requirements.

This scalability is particularly advantageous in industries such as automotive, aerospace, and consumer electronics, where rapid prototyping and short lead times are critical. Designers can iterate on prototypes quickly without investing in costly tooling multiple times. For large production runs, automated wax pattern production and ceramic shell coating processes help maintain consistent quality while increasing throughput, making investment casting a highly versatile solution across production volumes.

7. Enhanced Mechanical Properties

Parts created with this method often exhibit superior mechanical properties, including increased tensile strength, improved fatigue resistance, and enhanced hardness. Controlled cooling and solidification promote fine-grain microstructures, strengthening the metal and improving durability.

These enhanced properties are essential for high-performance components. Aerospace turbine blades, for example, operate under extreme rotational speeds, thermal stresses, and environmental conditions. Similarly, in the energy and automotive sectors, precision-cast parts withstand repetitive mechanical loads and stress, reducing maintenance needs and extending service life.

8. Cost-Effectiveness for Complex Parts

Although the initial tooling and setup costs for investment casting may be higher compared to simpler casting methods, the process proves cost-effective when producing complex parts in medium to large quantities. The reduction in material waste, minimized secondary machining, and ability to combine multiple features into a single component significantly lower per-unit costs.

Additionally, الصب الاستثماري eliminates the need for assembling multiple parts to achieve complex geometries. For example, a multi-component assembly in aerospace or automotive can often be replaced with a single investment cast piece, saving on assembly labor, fasteners, and inspection costs. The cumulative savings in production, material, and assembly make investment casting a highly economical choice for intricate and high-performance components.

Comparison of Investment Casting with Other Casting Methods

| ميزة | الاستثمار في الصب | صب الرمل | صب القوالب |

|---|---|---|---|

| Precision | عالي | قليل | واسطة |

| تشطيب السطح | ممتاز | Rough | جيد |

| Complex Geometry Capability | ممتاز | محدود | جيد |

| Material Range | واسع | محدود | محدود |

| Production Volume | Low to High | عالي | عالي |

| Secondary Machining | Minimal | Extensive | معتدل |

خاتمة

Investment casting stands out as a superior manufacturing process for producing complex, high-precision metal components. Its ability to achieve exceptional dimensional accuracy, intricate geometries, and superior surface finishes makes it indispensable in industries where performance and reliability are critical. The versatility in material selection and scalability of production further enhance its appeal. As industries continue to demand more sophisticated and efficient components, investment casting remains a strategic choice for manufacturers aiming to meet these evolving requirements.

الأسئلة الشائعة

Q1: What types of materials can be used in investment casting?

Investment casting supports a wide range of materials, including stainless steel, carbon steel, aluminum alloys, and superalloys. This versatility allows for the selection of materials that best meet the specific requirements of each application.

Q2: How does investment casting compare to other casting methods?

Compared to sand casting and die casting, investment casting offers higher precision, better surface finishes, and the ability to produce more complex geometries. However, it may have higher initial tooling costs, which are offset by the benefits in precision and material efficiency.

Q3: Is investment casting suitable for both small and large production runs?

Yes, investment casting is highly adaptable and can be scaled to accommodate both small-batch and large-scale production, making it suitable for a variety of manufacturing needs.

Q4: What industries benefit most from investment casting?

Industries such as aerospace, automotive, medical, and machinery manufacturing benefit significantly from investment casting due to its ability to produce complex, high-precision components.

Q5: Does investment casting require extensive post-processing?

Due to its high precision and excellent surface finish, investment casting often requires minimal post-processing, reducing both time and costs associated with additional machining.

Q6: Can investment casting produce parts with internal passages or hollow sections?

Yes, investment casting is particularly well-suited for creating components with internal passages, hollow sections, or complex cavities. The wax pattern can incorporate cores that form these internal features, allowing designers to produce intricate geometries that would be challenging with traditional casting methods. This is especially useful in aerospace components, hydraulic systems, and heat exchangers.

Q7: What is the typical size range of parts that can be investment cast?

Investment casting is highly versatile and can produce parts ranging from a few grams to several tens of kilograms. Small, detailed components like medical implants or intricate engine parts can be cast alongside larger components used in aerospace or industrial machinery, offering flexibility across multiple applications.

Q8: How does investment casting ensure repeatability and consistency in production?

The use of precision wax patterns and ceramic shell molds ensures high repeatability. Once the mold design is finalized, multiple parts can be produced with consistent dimensions, mechanical properties, and surface quality. Automated production systems further enhance consistency, making investment casting ideal for both prototyping and mass production.

Q9: Are there limitations to the complexity of designs that can be investment cast?

While investment casting can handle highly complex geometries, extremely large or extremely thin components may require additional design considerations. Engineers often work closely with casting specialists to optimize wall thicknesses, draft angles, and support structures to ensure successful production without defects.

Q10: How does investment casting contribute to sustainability in manufacturing?

Investment casting reduces material waste because of its near-net-shape capability, meaning parts are cast close to their final dimensions. Less machining and less scrap material are produced compared to other casting methods. Additionally, reusable wax patterns and efficient furnace technologies contribute to lower energy consumption and a smaller environmental footprint.

Q11: Can investment casting be used for prototype development?

Yes, investment casting is ideal for rapid prototyping of metal components. Designers can create accurate prototypes that closely replicate the final part’s material, surface finish, and mechanical properties. This enables functional testing and design validation before committing to full-scale production.

ابقى على اتصال معنا

شكرًا لقراءتكم! نأمل أن تكون هذه المدونة قد زودتكم بمعلومات قيّمة وإلهام حول أسقف الألواح الصوتية. إذا أعجبكم المحتوى وترغبون في البقاء على اطلاع بأحدث الصيحات والنصائح والتحديثات من وراء الكواليس، يسعدنا التواصل معكم عبر وسائل التواصل الاجتماعي.

📘 تابعونا على الفيسبوك: شركة شنغهاي لييروو الصناعية التجارية المحدودة

انضم إلى مجتمعنا المتنامي حيث نشارك نصائح الخبراء وتسليط الضوء على المنتجات والمناقشات التفاعلية مع المحترفين وعشاق التصميم من جميع أنحاء العالم.

دعونا نواصل المحادثة - نراكم هناك!

فئات المنتجات

- أجزاء الصمامات

- أجزاء مضخة المياه

- أجزاء صندوق المحمل

- أجزاء الصب بالقالب

- منتجات مضخات الفولاذ المقاوم للصدأ

- منتجات مضخات الحديد الزهر

- قطع غيار الصمامات لاستخدام السيارات

- قطع غيار السيارات

- أجزاء الصمامات للاستخدام المدني

- قطع غيار مضخة التفريغ KF