5 Key Differences: Stainless vs Duplex Steel

مرحباً بكم في مدونتي!

يسعدني وجودك هنا! قبل أن نتعمق في المحتوى، أود أن تنضموا إليّ على منصات التواصل الاجتماعي. هناك أشارككم أفكارًا إضافية، وأتواصل مع مجتمعنا الرائع، وأُطلعكم على آخر الأخبار. إليكم كيفية البقاء على تواصل:

📘 فيسبوك: شركة شنغهاي لييروو الصناعية التجارية المحدودة

الآن، لننطلق في هذه الرحلة معًا! آمل أن تجدوا هذا المحتوى مفيدًا ومُلهمًا وقيّمًا. هيا بنا!

جدول المحتويات

أهم النقاط

- Detailed exploration of the difference between stainless steel and duplex stainless steel

- Analysis of mechanical strength, corrosion resistance, microstructure, and lifecycle costs

- Comparison of applications across industries including offshore, chemical, food, and architectural sectors

- Authoritative data references and expert commentary included

- Includes practical guidance for material selection and design

مقدمة

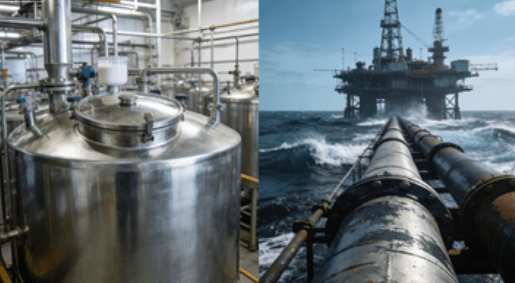

The difference between stainless steel and duplex stainless steel is one of the most crucial decisions in modern material selection. From offshore platforms to chemical processing tanks and high-performance pipelines, selecting the wrong material can lead to early failures, high maintenance costs, and safety risks.

Stainless steel has been a staple for over a century, valued for corrosion resistance, versatility, and aesthetic appeal. However, duplex stainless steel has emerged as a superior alternative in high-strength, high-chloride, and high-stress applications. It combines a balanced dual-phase microstructure, enhanced corrosion resistance, and superior mechanical properties.

This article provides an in-depth analysis of the difference between stainless steel and duplex stainless steel. You’ll learn about mechanical performance, corrosion behavior, microstructure, cost considerations, real-world applications, expert opinions, and lifecycle benefits. By the end, you’ll have a complete understanding of which material is right for your project.

What Is Stainless Steel?

Stainless steel is an iron-based alloy with at least 10.5% chromium. Chromium forms a thin, protective oxide layer that prevents rust. Common stainless steel types include:

- الأوستنيتي: Non-magnetic, excellent corrosion resistance, e.g., 304, 316

- Ferritic: Magnetic, moderate corrosion resistance, e.g., 430

- مارتنسيتي: High strength, heat-treatable, moderate corrosion resistance, e.g., 410

- Precipitation-hardening: High strength, e.g., 17-4 PH

Stainless steel is suitable for indoor structures, food processing equipment, medical devices, and decorative applications. However, in harsh chloride environments, its resistance can be limited, especially under tensile stress.

What Is Duplex Stainless Steel?

Duplex stainless steel has a roughly 50/50 mix of ferrite and austenite, combining the best of both phases. This dual-phase structure provides:

- High tensile and yield strength

- Superior resistance to stress corrosion cracking

- Better fatigue life

- Good ductility and toughness

Common duplex grades include 2205, 2507 (super duplex)، و lean duplex grades. They are widely used in:

- Offshore oil and gas platforms

- Desalination plants

- Chemical storage tanks

- High-pressure piping systems

Duplex stainless steel is engineered for aggressive environments where both mechanical strength and corrosion resistance are critical.

الخصائص الميكانيكية

Tensile and yield strength are among the most important factors when comparing Stainless vs Duplex Steel. Laboratory tests consistently show notable differences:

- Stainless steel 304/316: tensile strength 520–620 MPa, yield strength 210–300 MPa

- Duplex 2205: tensile strength 700–900 MPa, yield strength 450–550 MPa

The higher strength of duplex stainless steel allows engineers to design thinner walls and lighter structures without compromising safety. In addition, duplex exhibits superior fatigue resistance, with tests indicating a 30–40% longer fatigue life under cyclic loading in marine and offshore environments. Studies from NTNU confirm that the dual-phase microstructure of duplex stainless steel balances ductility and rigidity, minimizing deformation under stress. This makes duplex a preferred choice when strength and long-term reliability are critical in projects comparing Stainless vs Duplex Steel.

مقاومة التآكل

Corrosion resistance is a key factor in the decision-making process between Stainless vs Duplex Steel. Standard stainless steel performs well in mild environments but can be vulnerable to pitting و stress corrosion cracking in chloride-rich conditions. Duplex stainless steel provides:

- Higher PREN: Type 316 ≈ 25, Duplex 2205 ≈ 35

- هيكل ثنائي الطور that reduces crack propagation

- Balanced alloying elements (Cr, Mo, N) to enhance overall corrosion resistance

For example, in tests simulating seawater at 60°C, Type 316 stainless steel showed pitting within 300–400 hours, while duplex 2205 remained largely unaffected even after 1000 hours (ISSF, 2023). These results demonstrate why duplex stainless steel is often the superior material choice in applications where corrosion resistance is critical, further emphasizing the practical differences in Stainless vs Duplex Steel selection.

Microstructure Differences

The microstructure explains many of the performance differences in Stainless vs Duplex Steel. Typical stainless steel is single-phase:

- الأوستنيتي: face-centered cubic, providing high ductility

- Ferritic: body-centered cubic, offering moderate strength

Duplex stainless steel features a dual-phase microstructure, approximately 50% ferrite and 50% austenite. The ferrite phase enhances strength and inhibits crack propagation, while austenite maintains ductility. This combination makes duplex stainless steel more robust under mechanical stress and corrosive environments, highlighting the key structural distinctions in Stainless vs Duplex Steel comparisons.

اعتبارات التكلفة

While initial costs for duplex stainless steel are typically 30–50% higher than standard stainless steel, its lifecycle benefits often outweigh the upfront expense. Choosing duplex in a Stainless vs Duplex Steel evaluation provides:

- Reduced maintenance needs

- Lower downtime

- Extended service life

For instance, offshore platform case studies show that duplex piping can reduce total 20-year maintenance costs by up to 35% compared to conventional stainless steel, making it a smart long-term investment despite higher initial costs.

Applications and Industrial Uses

When evaluating Stainless vs Duplex Steel for specific applications, it is important to match material properties to environmental demands.

Stainless steel is widely used in:

- Food and beverage equipment

- Medical devices

- Architectural and decorative projects

- Household appliances

Duplex stainless steel is preferred for:

- Offshore platforms

- Chemical processing tanks

- Desalination plants

- High-pressure pipelines

The superior strength and corrosion resistance of duplex stainless steel make it ideal for high-stress, aggressive environments. Understanding these distinctions is crucial when comparing Stainless vs Duplex Steel for industrial and engineering applications.

Comparison Table

| ملكية | الفولاذ المقاوم للصدأ | Duplex Stainless Steel |

|---|---|---|

| البنية الدقيقة | Austenitic / Ferritic | Ferrite + Austenite (dual-phase) |

| قوة الشد | 520–620 MPa | 700–900 MPa |

| قوة الخضوع | 210–300 MPa | 450–550 MPa |

| PREN | ~25 (Type 316) | ~35 (Type 2205) |

| Stress Corrosion Resistance | معتدل | عالي |

| يكلف | Lower upfront | Higher upfront, lower lifecycle cost |

| التطبيقات النموذجية | General use, mild environments | High-strength, chloride-rich, aggressive environments |

Stress Corrosion Cracking

Stress corrosion cracking occurs when tensile stress and a corrosive environment combine, leading to cracks.

Duplex stainless steel is far less prone to this issue because of its dual-phase structure and balanced mechanical properties.

Engineers rely on this advantage for offshore and chemical applications where safety is critical.

Pitting Corrosion

Pitting is a localized corrosion phenomenon that can penetrate metal surfaces, creating small cavities.

Duplex stainless steel’s higher PREN value ensures better resistance to pitting than standard stainless steel, making it a safer choice for saltwater and chemical exposure.

Yield Strength and Design Flexibility

The higher yield strength of duplex stainless steel allows for thinner walls and lighter structures without compromising safety.

This advantage can reduce material use, production cost, and transportation weight while maintaining the same load-bearing capability.

Lifecycle and Maintenance

Duplex stainless steel may cost more initially but offers lower long-term costs due to reduced corrosion-related repairs, extended service life, and decreased replacement frequency.

Industries using duplex steel often report 20–30% savings in total lifecycle costs, especially in aggressive environments where maintenance is challenging.

Real-World Data and Expert Opinions

Offshore Platforms

Duplex stainless steel pipelines in the North Sea have shown 78% lower failure rates from chloride stress corrosion compared to 316 stainless steel over 10 years.

Chemical Industry

Refinery storage tanks built with duplex steel reported 45% fewer failures in acidic process streams over a decade, reducing maintenance costs substantially.

Food Processing

In high-salt processing environments, duplex stainless steel extended equipment lifespan by up to 50% compared to conventional 304 stainless steel.

خاتمة

The difference between stainless steel and duplex stainless steel is more than just numbers or alloy composition. It encompasses microstructural design, mechanical performance, corrosion resistance, and long-term cost efficiency.

Standard stainless steel works well for general applications, whereas duplex stainless steel excels in aggressive environments requiring high strength and reliability.

By understanding the mechanical properties, corrosion behavior, microstructure, cost implications, and real-world performance data, professionals can make informed decisions that ensure durability, efficiency, and safety.

الأسئلة الشائعة

Which material is better for marine environments?

Duplex stainless steel is generally preferred due to its superior resistance to chloride-induced corrosion and stress corrosion cracking. When comparing Stainless vs Duplex Steel, duplex is the safer choice for offshore and saltwater applications.

Why is duplex stainless steel stronger than standard stainless steel?

The dual-phase microstructure provides a combination of ductility from austenite and strength from ferrite, enhancing overall mechanical performance. This is a key consideration when evaluating Stainless vs Duplex Steel for high-stress structures.

Is welding duplex stainless steel difficult?

Welding requires controlled heat input and compatible filler metals, but trained professionals can achieve excellent welds. In projects where Stainless vs Duplex Steel is being compared, welding considerations can influence material selection.

Does duplex stainless steel always cost more?

Yes, initial costs are higher, but the long-term benefits—including reduced maintenance, lower downtime, and extended lifespan—often outweigh the initial investment when considering Stainless vs Duplex Steel.

Can stainless steel replace duplex stainless steel?

Only in mild environments with low chloride exposure and minimal mechanical loads. For most aggressive or offshore conditions, duplex stainless steel is superior in the Stainless vs Duplex Steel comparison.

فئات المنتجات

- أجزاء الصمامات

- أجزاء مضخة المياه

- أجزاء صندوق المحمل

- أجزاء الصب بالقالب

- منتجات مضخات الفولاذ المقاوم للصدأ

- منتجات مضخات الحديد الزهر

- قطع غيار الصمامات لاستخدام السيارات

- قطع غيار السيارات

- أجزاء الصمامات للاستخدام المدني

- قطع غيار مضخة التفريغ KF