5 أخطاء شائعة في صب المكره

مرحباً بكم في مدونتي!

يسعدني وجودك هنا! قبل أن نتعمق في المحتوى، أود أن تنضموا إليّ على منصات التواصل الاجتماعي. هناك أشارككم أفكارًا إضافية، وأتواصل مع مجتمعنا الرائع، وأُطلعكم على آخر الأخبار. إليكم كيفية البقاء على تواصل:

📘 فيسبوك: شركة شنغهاي لييروو الصناعية التجارية المحدودة

الآن، لننطلق في هذه الرحلة معًا! آمل أن تجدوا هذا المحتوى مفيدًا ومُلهمًا وقيّمًا. هيا بنا!

جدول المحتويات

مقدمة

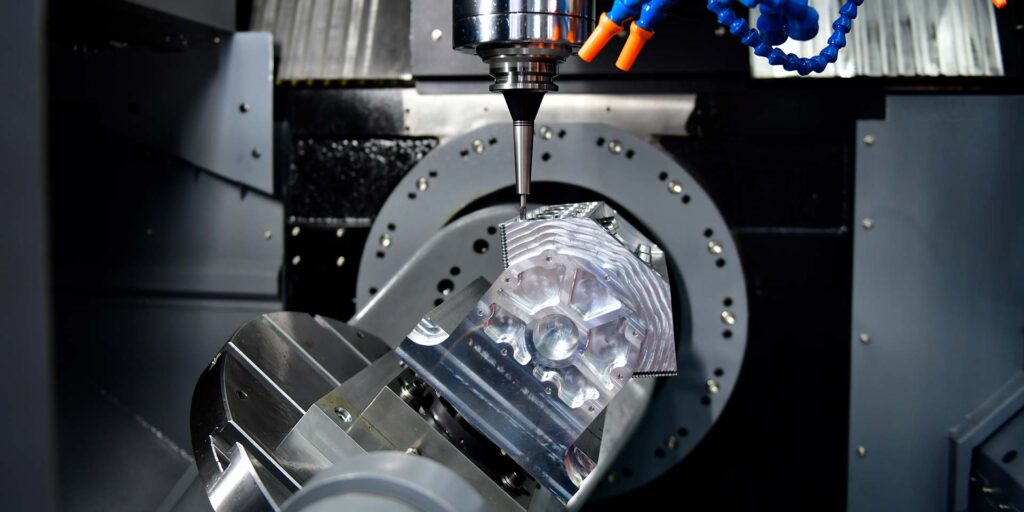

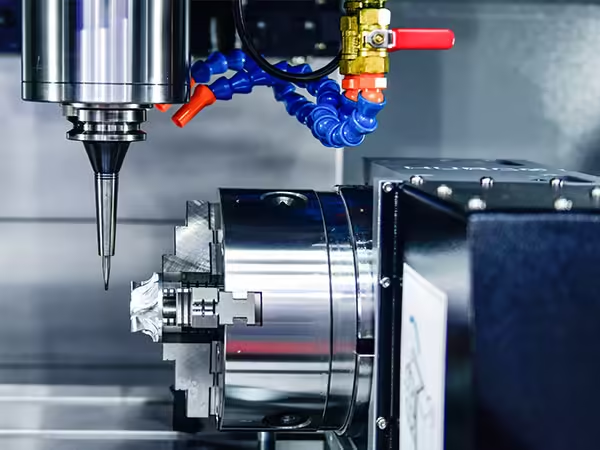

Impeller casting plays a pivotal role in various industries, especially where fluid dynamics and rotational motion are key. Precision in the impeller casting process ensures optimal efficiency, performance, and longevity of components used in pumps, turbines, compressors, and other industrial equipment. However, even minor mistakes in the casting process can lead to major performance issues, cost overruns, or safety hazards. In this article, we will explore five common impeller casting errors that buyers and manufacturers should be aware of, helping procurement professionals make informed decisions.

Understanding these typical pitfalls will empower buyers to ask the right questions, evaluate suppliers better, and ensure that the impeller casting components they purchase meet the required standards.

Incomplete Mold Filling in صب المكره

One of the most common issues in impeller casting is incomplete mold filling. This defect often arises due to low pouring temperature, improper gating design, or inadequate venting. When molten metal fails to fully occupy the mold cavity, the final product will have voids or missing features, rendering it structurally weak or completely unusable.

For buyers, detecting this defect early is crucial. Visual inspection, ultrasonic testing, and CT scanning can help reveal internal voids. It is also important to source from foundries that use simulation software to predict mold filling behavior before actual casting.

Poor Surface Finish in Cast Impellers

A rough or inconsistent surface finish not only affects the appearance of the impeller but also reduces its hydraulic efficiency. Surface finish issues in impeller casting may result from poor mold quality, low-quality alloys, improper sand compaction, or insufficient post-processing.

A poor surface finish increases friction and can disrupt fluid flow, leading to vibration, noise, and energy inefficiency in the equipment where the impeller is installed. Buyers should request surface finish specifications and ensure they are measured using tools like profilometers. It’s also wise to work with suppliers who offer value-added services like precision machining and polishing.

Impeller Casting Table: Common Errors and Their Impact

| Impeller Casting Error | Likely Cause | Potential Impact | Recommended Buyer Action |

|---|---|---|---|

| Incomplete Mold Filling | Low temp, poor gating, bad venting | Weak structure, reduced lifespan | Request NDT reports, use trusted foundries |

| Poor Surface Finish | Bad mold, improper alloy, low QC | Lower efficiency, increased energy use | Ask for surface roughness data |

| Shrinkage Defects | Inadequate risers or feeding | Internal voids, strength reduction | Require casting simulation review |

| Dimensional Inaccuracy | Pattern wear, misalignment | Poor fit in assemblies, performance issues | Demand inspection records |

| Cracks and Hot Tears | Rapid cooling, improper alloy mix | Complete part failure under stress | Insist on proper cooling control |

Dimensional Inaccuracy in صب المكره

Dimensional inaccuracy is another prevalent issue in impeller casting, particularly when patterns are not properly maintained or aligned. Even minor dimensional deviations can lead to severe fitting problems when the impeller is integrated into pump housings or motor shafts.

Buyers should always request 3D inspection reports or coordinate measuring machine (CMM) data from suppliers. Tolerances should align with the product’s operational requirements. Regular calibration of tools and digital scanning technologies can help manufacturers avoid this issue.

Shrinkage Defects Within Cast Impellers

Shrinkage defects happen when the molten metal contracts as it cools and solidifies, creating voids within the impeller. This typically occurs when the feeding system (risers and runners) is inadequately designed. In the case of impeller casting, such voids can compromise the mechanical strength of the product.

Procurement professionals should ensure that foundries use simulation software to design feeding systems and that they validate their results through destructive and non-destructive testing. Transparency from the supplier regarding their quality control process is critical.

Cracks and Hot Tearing in Cast Impellers

Cracking or hot tearing is a severe problem in impeller casting, often resulting from high thermal gradients or alloy composition mismatches. These cracks may not always be visible on the surface and can lead to catastrophic failure during operation.

To mitigate this, buyers should confirm whether the supplier controls cooling rates effectively and whether they perform internal inspections such as dye penetrant testing or X-ray analysis. Collaboration during the design stage can help avoid this costly defect.

خاتمة

Understanding common errors in impeller casting is the first step toward smarter sourcing decisions. Whether it’s avoiding incomplete mold fills, improving surface quality, or demanding dimensional accuracy, buyers can play a significant role in quality assurance by setting clear expectations and vetting suppliers rigorously.

When sourcing impeller casting components, consider engaging with suppliers who have a proven track record, use modern casting simulation tools, and are willing to provide detailed inspection reports. Investing time upfront can significantly reduce post-installation issues, warranty claims, and maintenance costs.

الأسئلة الشائعة

What is the most common impeller casting defect?

Incomplete mold filling is among the most frequently encountered issues in impeller casting. It typically results from low pouring temperatures, inadequate gating systems, or insufficient mold venting. This defect can lead to internal voids or incomplete features, which severely compromise the structural strength, efficiency, and safety of the final product.

How can I check for internal defects in cast impellers?

To accurately detect internal defects, buyers should rely on non-destructive testing (NDT) methods such as ultrasonic inspection, industrial CT scanning, and X-ray analysis. These techniques allow for a thorough examination of the internal structure without damaging the part, making them ideal for quality verification before final acceptance or installation.

Does surface finish really matter in impeller casting?

Yes, the surface finish plays a crucial role in both performance and durability. A smooth finish minimizes fluid turbulence and friction, leading to enhanced flow dynamics and reduced energy consumption. Moreover, it prevents buildup of deposits and wear over time. Ensuring consistent and high-quality surface finish can lower long-term operational costs and extend service life.

What documents should I request from impeller casting suppliers?

Buyers should always request a full quality assurance package that includes dimensional inspection reports, non-destructive testing results, raw material certifications, and casting simulation analysis. These documents provide transparency, confirm compliance with specifications, and help trace any potential quality issues back to the source.

Can poor impeller casting affect equipment lifespan?

Absolutely. Defective impeller castings can create serious operational problems such as imbalance, vibration, increased wear on bearings, and even catastrophic mechanical failure. Over time, these issues can significantly reduce equipment lifespan and drive up maintenance costs. Procuring well-made impeller castings is an essential investment in overall system reliability.

فئات المنتجات

- أجزاء الصمامات

- أجزاء مضخة المياه

- أجزاء صندوق المحمل

- أجزاء الصب بالقالب

- منتجات مضخات الفولاذ المقاوم للصدأ

- منتجات مضخات الحديد الزهر

- قطع غيار الصمامات لاستخدام السيارات

- قطع غيار السيارات

- أجزاء الصمامات للاستخدام المدني

- قطع غيار مضخة التفريغ KF