10 مواد متطورة تُشكل مستقبل صناعة صب الحديد

The iron casting industry has always been a cornerstone of industrial progress, supporting sectors from automotive manufacturing to construction and infrastructure. As demand for more durable, efficient, and eco-friendly materials increases, innovation within the industry is pushing boundaries. New and cutting-edge materials are taking center stage, offering solutions that address traditional challenges while enabling new capabilities for iron castings. This blog will explore 10 of these materials that are expected to shape the future of the iron casting industry, revolutionizing how products are created and enhancing their overall performance.

جدول المحتويات

مقدمة

ال صناعة صب الحديد, as a critical segment of manufacturing, has experienced tremendous changes over the years. These advancements not only focus on the casting processes but also involve breakthroughs in materials that improve efficiency, reduce costs, and meet the growing demand for sustainability. As industries evolve, the ability to adapt to these emerging materials can make the difference between a business thriving or falling behind.

In this blog, we will examine some of the most groundbreaking materials and technologies influencing the future of iron casting. These materials are improving casting precision, reducing weight, enhancing corrosion resistance, and even providing new methods for recycling. With global environmental concerns at the forefront, these innovations are not only providing practical advantages but are also contributing to more sustainable manufacturing practices.

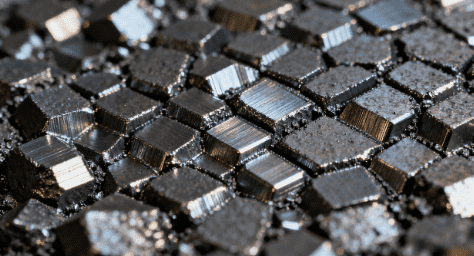

1. High-Performance Cast Iron Alloys

The Role of High-Performance Alloys in Iron Casting

High-performance cast iron alloys have long been a staple in the iron casting industry. However, recent advancements have led to the development of alloys with superior mechanical properties, such as improved wear resistance, higher thermal conductivity, and better fatigue resistance. These alloys are tailored to meet the specific needs of various industries, such as automotive, aerospace, and heavy machinery.

ال صناعة صب الحديد benefits from these materials because they help reduce the overall cost of production by extending the lifespan of castings and improving the reliability of components. Additionally, these alloys allow manufacturers to design components that can withstand extreme operating conditions.

Key Characteristics of High-Performance Alloys:

- Superior wear and corrosion resistance

- Increased strength and durability

- Ability to withstand higher temperatures

- Enhanced machinability and surface finish

2. Ductile Iron (Nodular Cast Iron)

The Benefits of Ductile Iron for Iron Casting

Ductile iron, or nodular cast iron, has gained popularity in the iron casting industry due to its ability to combine the excellent casting properties of cast iron with the ductility and toughness of steel. Ductile iron is created by adding small amounts of alloying elements, which form graphite nodules within the structure, enhancing the material’s overall properties.

One of the primary benefits of ductile iron in casting is its ability to resist impact and fatigue, making it ideal for high-stress applications like automotive engine blocks and machinery components.

Advantages of Ductile Iron:

- Improved tensile strength

- Higher impact resistance

- Enhanced fatigue resistance

- Cost-effective alternative to steel

3. Composite Materials for Iron Casting

How Composite Materials are Revolutionizing the Iron Casting Industry

Composite materials, combining metals with non-metallic elements like carbon fibers or ceramics, are increasingly being used in iron casting. These materials offer the advantages of reduced weight, improved strength, and enhanced durability. In the context of iron casting, composites can significantly improve the performance of cast parts, especially in industries that require high-strength, lightweight materials, such as aerospace and automotive.

The unique properties of composite materials help to address some of the major challenges in the iron casting industry, such as reducing energy consumption and improving material efficiency.

Key Benefits of Composite Materials:

- Reduced weight while maintaining strength

- Enhanced resistance to wear and corrosion

- Better thermal properties and heat resistance

- Greater design flexibility for complex components

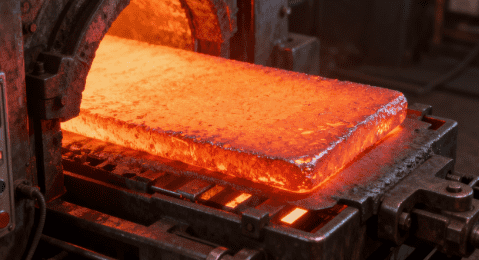

4. High-Temperature Resistant Materials

Importance of High-Temperature Materials in Iron Casting

The ability to withstand high temperatures is crucial for many applications in the iron casting industry. High-temperature resistant materials such as ceramics and advanced alloys play an essential role in casting high-performance components, particularly for the automotive and aerospace industries, where parts are exposed to extreme conditions.

As the demand for more energy-efficient engines and machines increases, these materials are becoming more essential. They help prevent the degradation of iron castings, thereby improving the performance and longevity of components under high-stress conditions.

Key Features of High-Temperature Materials:

- Resistance to thermal shock and oxidation

- Capability to maintain strength at elevated temperatures

- Reduced thermal expansion

- Enhanced durability in high-stress applications

5. Green Sand Molding Materials

The Role of Sustainable Sand Molding in Iron Casting

Green sand molding is one of the oldest and most widely used methods in the صناعة صب الحديد. Recent innovations have improved the quality of green sand, making it more reusable and environmentally friendly. The materials used in green sand molding are undergoing continuous improvement to reduce the environmental impact of casting.

The green sand process uses a mixture of sand, clay, and water to create molds for casting iron. In recent years, innovations such as synthetic and reclaimed sand have enhanced the casting process, making it more sustainable without sacrificing performance.

Advantages of Green Sand Molding:

- Reusable materials that reduce waste

- Cost-effective compared to other molding methods

- Improved environmental sustainability

- High-quality mold surface finish

6. 3D Printed Casting Materials

The Future of 3D Printing in Iron Casting

The use of 3D printing technology in the صناعة صب الحديد has gained significant attention in recent years. By using 3D printing to create molds and core prints, manufacturers can produce complex geometries and designs that would be difficult or impossible to achieve with traditional methods. These molds and cores can be made from materials like sand, ceramics, or metal, offering greater flexibility and precision in iron casting.

3D printing in iron casting also reduces waste by only using the material necessary to create the mold, contributing to more sustainable production practices.

Key Advantages of 3D Printing:

- Ability to create complex and intricate designs

- Faster production times

- Reduced material waste

- Customization and flexibility

7. Aluminum-Alloyed Cast Iron

How Aluminum-Alloyed Cast Iron Enhances Iron Casting

Aluminum-alloyed cast iron has become an important material in the iron casting industry. The addition of aluminum to cast iron improves its properties, particularly in terms of corrosion resistance and lightweight performance. This material is increasingly used in applications where reducing weight is crucial, such as in the automotive industry for engine components.

Aluminum-alloyed cast iron retains many of the beneficial properties of traditional cast iron but with added advantages that make it more suitable for modern applications.

Benefits of Aluminum-Alloyed Cast Iron:

- مقاومة التآكل المحسنة

- Reduced weight for specific applications

- Increased tensile strength and fatigue resistance

- Improved casting performance

8. Nanomaterials in Iron Casting

The Emerging Role of Nanomaterials in Iron Casting

Nanotechnology is revolutionizing the materials science field, and the iron casting industry is no exception. The introduction of nanomaterials can significantly enhance the properties of cast iron by improving strength, wear resistance, and even heat resistance at the microscopic level. These advancements are made possible by manipulating the material at the nanoscale to achieve desirable properties.

Nanomaterials can offer improved mechanical performance and thermal stability, which is particularly beneficial in applications such as high-performance engines and industrial machinery.

Key Advantages of Nanomaterials:

- Enhanced mechanical properties

- Better wear and corrosion resistance

- Increased thermal stability

- Potential for reduced weight without compromising strength

9. Silicon Carbide-Based Castings

Why Silicon Carbide is Crucial for Iron Casting

Silicon carbide (SiC) is increasingly being used in iron casting applications due to its hardness, high thermal conductivity, and resistance to oxidation. It’s particularly beneficial in harsh industrial environments where components need to withstand extreme temperatures and corrosive conditions.

Incorporating silicon carbide into the casting process can significantly enhance the longevity and performance of cast iron parts, especially those used in high-temperature or heavy-duty applications.

Benefits of Silicon Carbide in Castings:

- High resistance to heat and wear

- Improved mechanical strength and hardness

- Enhanced oxidation resistance

- Suitable for high-performance applications

10. Recycled Materials in Iron Casting

The Role of Recycling in Sustainable Iron Casting

Recycling plays a pivotal role in shaping the future of the iron casting industry. The industry is increasingly focusing on incorporating recycled iron and scrap materials into the casting process to reduce environmental impact and conserve natural resources. Innovations in recycling technologies have made it possible to produce high-quality castings from scrap iron, reducing energy consumption and material waste.

Recycled materials in the iron casting industry help minimize the reliance on virgin raw materials and contribute to a circular economy.

Advantages of Using Recycled Materials:

- Reduced energy consumption in production

- Lower environmental impact

- Conservation of natural resources

- Cost-effective production process

A Comparative Table of Cutting-Edge Materials in the Iron Casting Industry

| مادة | Key Benefits | Primary Application |

|---|---|---|

| High-Performance Cast Iron Alloys | Wear resistance, high strength, durability | Automotive, heavy machinery |

| Ductile Iron (Nodular Cast Iron) | Impact resistance, tensile strength | Engine blocks, machinery |

| المواد المركبة | Lightweight, improved strength, durability | Aerospace, automotive |

| High-Temperature Resistant Materials | Thermal stability, resistance to oxidation | Aerospace, automotive |

| Green Sand Molding Materials | Reusability, sustainability, cost-effective | General casting |

| 3D Printed Casting Materials | Complex designs, faster production, reduced waste | Automotive, industrial |

| Aluminum-Alloyed Cast Iron | Corrosion resistance, lightweight | Engine components, automotive |

| Nanomaterials | Enhanced strength, wear resistance, thermal stability | High-performance engines |

| Silicon Carbide-Based Castings | High heat resistance, hardness, oxidation resistance | High-temperature applications |

| Recycled Materials | Sustainable, energy-saving, cost-effective | General casting |

خاتمة

ال iron casting industry is poised for significant transformation thanks to the adoption of new materials that address the increasing demand for performance, sustainability, and cost efficiency. From high-performance alloys to the use of recycled materials and cutting-edge nanotechnology, these innovations are paving the way for a more advanced and eco-friendly industry. As the market continues to evolve, those who embrace these advancements will be better positioned to meet the challenges of the future.

The integration of these cutting-edge materials is crucial not just for the success of individual companies but for the broader industry’s ability to remain competitive in an increasingly globalized and environmentally conscious world.

الأسئلة الشائعة

How will high-performance cast iron alloys impact the صناعة صب الحديد?

High-performance cast iron alloys will help improve the mechanical properties of castings, such as wear resistance and strength, leading to longer-lasting components and more reliable products.

What is the role of 3D printing in iron casting?

3D printing allows for the creation of complex and precise molds, reducing material waste and production time while enabling intricate designs that traditional methods cannot achieve.

Are recycled materials becoming more important in the صناعة صب الحديد?

Yes, recycled materials are increasingly being incorporated into the iron casting process to reduce environmental impact, conserve resources, and lower production costs.

Why is ductile iron preferred in certain applications?

Ductile iron is valued for its improved tensile strength and impact resistance, making it ideal for high-stress applications like automotive engine blocks and industrial machinery components.

What makes aluminum-alloyed cast iron a better choice for certain industries?

Aluminum-alloyed cast iron offers enhanced corrosion resistance and reduced weight, making it an excellent choice for automotive components, especially in engines and performance parts.

ابقى على اتصال معنا

شكرًا لقراءتكم! نأمل أن تكون هذه المدونة قد زودتكم بمعلومات قيّمة وإلهام حول أسقف الألواح الصوتية. إذا أعجبكم المحتوى وترغبون في البقاء على اطلاع بأحدث الصيحات والنصائح والتحديثات من وراء الكواليس، يسعدنا التواصل معكم عبر وسائل التواصل الاجتماعي.

📘 تابعونا على الفيسبوك: شركة شنغهاي لييروو الصناعية التجارية المحدودة

انضم إلى مجتمعنا المتنامي حيث نشارك نصائح الخبراء وتسليط الضوء على المنتجات والمناقشات التفاعلية مع المحترفين وعشاق التصميم من جميع أنحاء العالم.

دعونا نواصل المحادثة - نراكم هناك!

فئات المنتجات

- أجزاء الصمامات

- أجزاء مضخة المياه

- أجزاء صندوق المحمل

- أجزاء الصب بالقالب

- منتجات مضخات الفولاذ المقاوم للصدأ

- منتجات مضخات الحديد الزهر

- قطع غيار الصمامات لاستخدام السيارات

- قطع غيار السيارات

- أجزاء الصمامات للاستخدام المدني

- قطع غيار مضخة التفريغ KF