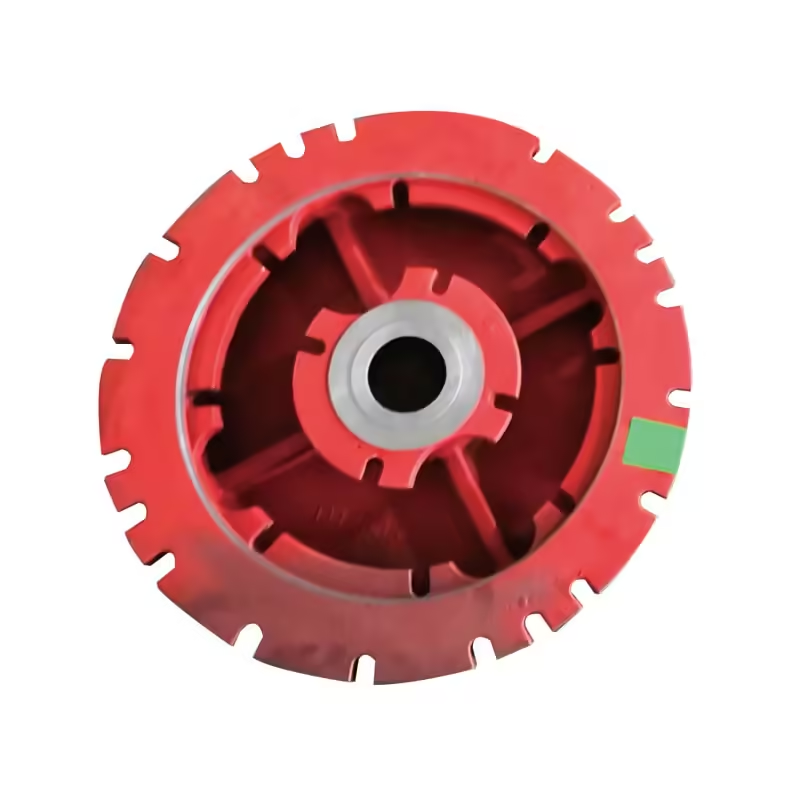

Perumahan Pam Besi Tuang

Perumahan Pam Besi Tuang

Tingkatkan sistem pam anda dengan produk kami yang tahan lama Perumahan Pam Besi Tuang, direka bentuk untuk kekuatan dan kebolehpercayaan dalam keadaan yang mencabar. Perumahan Pam Besi Tuang kami memastikan prestasi optimum dan jangka hayat yang panjang untuk aplikasi perindustrian. Percayakan komponen kejuruteraan ketepatan kami untuk fungsi yang lancar dan hasil yang mantap. Terokai rangkaian kami hari ini untuk penyelesaian pengepaman yang unggul.

Tingkatkan sistem pam anda dengan produk kami yang tahan lama Perumahan Pam Besi Tuang, direka bentuk untuk kekuatan dan kebolehpercayaan dalam keadaan yang mencabar. Perumahan Pam Besi Tuang kami memastikan prestasi optimum dan jangka hayat yang panjang untuk aplikasi perindustrian. Percayakan komponen kejuruteraan ketepatan kami untuk fungsi yang lancar dan hasil yang mantap. Terokai rangkaian kami hari ini untuk penyelesaian pengepaman yang unggul.

Tingkatkan sistem pam anda dengan perumah pam besi Tuang kami yang teguh, direka bentuk untuk kekuatan maksimum, rintangan kakisan dan prestasi yang tahan lama. Dibina untuk menahan persekitaran tekanan tinggi, suhu tinggi dan kasar, perumah pam besi Tuang kami menyediakan integriti struktur yang diperlukan untuk operasi yang andal dalam pelbagai aplikasi perindustrian dan komersial. Sama ada digunakan dalam pemprosesan kimia, rawatan air, perlombongan atau sistem HVAC, perumah tugas berat ini memberikan ketahanan yang diperlukan oleh peralatan anda.

Setiap perumah pam besi tuang dituang dan dimesin dengan tepat mengikut toleransi yang ketat, memastikan penjajaran yang sangat baik, rintangan getaran dan keperluan penyelenggaraan yang minimum. Bahan besi tuang berkualiti tinggi menawarkan sifat mekanikal yang unggul, termasuk pelesapan haba yang sangat baik dan pengurangan haus dari semasa ke semasa—penting untuk mengekalkan kestabilan operasi dan mengurangkan masa henti peralatan.

Sama ada anda menggantikan komponen yang haus atau membina sistem baharu dari bawah ke atas, perumah pam besi tuang kami menawarkan penyelesaian yang dipercayai dan kos efektif yang menyokong prestasi pam yang konsisten dan melindungi komponen dalaman daripada tekanan luaran. Terokai rangkaian penuh kami hari ini untuk mencari perumah pam besi tuang yang ideal untuk keperluan pengepaman khusus anda.

- Lebih daripada 60 jenis bahan, lebih daripada sedozen aloi, dan 70 jenis nombor.

- Banyak produk boleh dihasilkan, 3500+ acuan tuangan ketepatan, 1000+ Aksesori pengeluaran boleh menjadi besar atau kecil.

- Satu produk seberat 50 kg boleh disesuaikan.

- Pelbagai relau tersedia untuk pemilihan, dan kepingan tunggal 50 kg hingga 850 kg boleh dihasilkan.

- 20 tahun sarjana, pengalaman yang kaya, memasuki industri pada tahun 1980-an, peneraju industri.

- Produk boleh dikesan, dan setiap produk relau mempunyai sijil: 3.1 Sijil Bahan.

- Pelanggan boleh meminta agensi ujian pihak ketiga untuk mengeluarkan sijil 3.2.

- Memproses produk halus boleh dikeluarkan dengan sijil pemprosesan.

Kelebihan Leierwo dalam menuang tuangan ketepatan dalam industri tuangan pam

Produk pam biasanya memerlukan ketepatan tuangan yang tinggi dan sifat bahan, dan kepakaran Leierwo dalam tuangan pam amat menonjol. Aplikasi meluas syarikat dalam aksesori pam dan injap menunjukkan penguasaannya dalam proses penuangan untuk komponen utama seperti badan pam, pendesak dan lengan. Teknologi tuangan ketepatan berkesan mengawal keseragaman ketebalan dinding tuangan dan ketepatan rongga dalaman, mengurangkan pemprosesan seterusnya dan meningkatkan kecekapan keseluruhan. Tambahan pula, syarikat boleh mengesyorkan proses tuangan yang paling sesuai berdasarkan struktur komponen untuk mengoptimumkan lagi prestasi produk pam dan memenuhi rintangan kakisan, rintangan haba dan keperluan dinamik bendalir pelbagai industri.

Pemilihan bahan utama

Tuangan pam terdedah kepada media cecair untuk tempoh yang lama dan sering menghadapi cabaran seperti kakisan, haus dan peronggaan. Oleh itu, bahan mesti mempunyai rintangan kakisan dan haus yang tinggi, serta sifat tuangan yang sangat baik.

Bahan Biasa:

Siri Keluli Tahan Karat:

316/316L: Diutamakan untuk selongsong pam, pendesak dan aci, tahan kepada asid, alkali dan kakisan ion klorida. 2205 Keluli Dupleks: Kekuatan tinggi dan rintangan pitting tinggi, sesuai untuk pam air laut dan pam kimia. 304/304L: Komponen pam kegunaan am, sesuai untuk rawatan air dan industri makanan. Siri Keluli Karbon:

1045: Untuk aci pam dan selongsong dalam persekitaran tidak menghakis. 4130: Untuk komponen struktur pam suhu tinggi dan tekanan tinggi.

Siri Aloi Khas:

C95400 Gangsa: Sesuai untuk lengan pam air laut dan komponen gelongsor, menawarkan rintangan haus dan pelinciran diri yang sangat baik.

Aloi Kobalt (seperti Co6): Digunakan untuk menutup permukaan atau pendesak dalam pam haus tinggi dan suhu tinggi.

Pilihan perkhidmatan pemutus utama

Prestasi dinamik bendalir komponen pam (seperti pendesak dan badan pam) bergantung pada ketepatan tuangan, dan jenis perkhidmatan ini mempunyai pembahagian kerja yang jelas!

Pemutus pelaburan: Menguasai bahagian laluan aliran kompleks. Pendesak ialah jantung pam, dan lengkung bilahnya (yang mesti mematuhi reka bentuk dinamik bendalir) mempunyai bentuk yang kompleks. Sisihan dimensi secara langsung mengurangkan kecekapan pam. Tuangan pelaburan boleh mencapai ketepatan profil bilah +0.1mm dan kemasan permukaan Ra3.2um atau kurang, mengurangkan rintangan bendalir.

Tuangan pasir: Digunakan untuk komponen asas seperti badan pam. Badan pam, sebagai cangkang luar, mempunyai bentuk yang agak teratur (kebanyakannya silinder atau persegi). Dalam pengeluaran besar-besaran, tuangan pasir menawarkan kos rendah dan masa kitaran pendek, memenuhi keperluan asas "sokongan struktur + laluan aliran bendalir."

Pemesinan CNC: Memastikan penghantaran dan ketepatan pengedap. Sambungan antara aci pam dan pendesak, serta permukaan pengedap antara badan pam dan penutup hujung, memerlukan pemesinan CNC untuk memastikan konsentriksi (≤0.01mm) dan kerataan untuk mengelakkan getaran atau kebocoran yang disebabkan oleh kesipian semasa operasi.