Tembaga dan Aloinya

Copper and its alloys are widely used in precision casting, boasting excellent electrical and thermal conductivity, corrosion resistance, and high strength. Their superior casting properties make them an ideal choice for many high-precision, high-performance components. Copper alloys play a vital role in many industrial sectors, particularly those requiring high electrical conductivity and wear resistance, such as the electronics, automotive, and energy industries.

In precision casting, copper and its alloys are commonly used to produce complex, high-precision, and high-temperature resistant components. The advantages of copper alloys lie in their excellent mechanical properties and corrosion resistance, which ensure long-term stability and reliability, making them particularly suitable for applications requiring high performance and a long life.

In precision casting, copper and its alloys are commonly used to produce complex, high-precision, and high-temperature resistant components. The advantages of copper alloys lie in their excellent mechanical properties and corrosion resistance, which ensure long-term stability and reliability, making them particularly suitable for applications requiring high performance and a long life.

Common Material Grades of Copper and Its Alloys

| Gred Aloi | Nama Aloi | Sifat Bahan | Industri Aplikasi | Contoh Widget |

| Cu-ETP (C11000) | Electrolytic Copper | Good electrical conductivity, thermal conductivity, high ductility, strong corrosion resistance | Electronics, precision instruments, air conditioners, heat exchangers | Electrical contacts, heat exchanger tubes, terminal blocks |

| Cu-Zn (Brass) | H59, H62, H63 | Good mechanical properties, high strength and corrosion resistance, easy to process | Precision casting, automobiles, mechanical parts, ships | Gears, valves, pump bodies, mechanical connectors |

| Cu-Sn (Bronze) | H70, H80, H90 | Excellent wear and corrosion resistance, good elasticity and strength | Shipbuilding, engineering machinery, military | Guide rails, springs, castings |

| Cu-Ni (Aluminum Bronze) | C61500, C63000 | Excellent wear resistance and corrosion resistance, especially in seawater corrosion environment | Shipbuilding, marine engineering, and nuclear industry | Seawater pumps, ship propellers, corrosion-resistant components |

| Cu-Al (Aluminum Bronze) | CAl5, CAl10 | High strength, good corrosion resistance, strong high temperature resistance | Aerospace, automotive, high temperature engineering | Turbine blades, valves, engine parts |

| Cu-Sn-Pb (Lead Bronze) | C93200, C93600 | Good self-lubricating performance, wear resistance, suitable for high load work | Machinery, metallurgy, papermaking | Bearings, sliders, gears |

| Cu-Ag (Silver-Copper Alloy) | C17500 | High electrical conductivity, excellent weldability and oxidation resistance | High-precision electronic equipment and communication equipment | High-frequency components, electrical contacts, and ultra-high-frequency components |

Copper and Its Alloy Casting Technology

Tuangan Pasir

Applicable copper alloys: brass (Cu-Zn), bronze (Cu-Sn), aluminum bronze (Cu-Al)

ciri-ciri:Moderate Cost: Sand casting is a relatively low-cost process suitable for medium-volume production.

High Adaptability: Suitable for casting complex geometries and larger components.

Wide Material Selection: Suitable for a variety of copper alloys, offering significant advantages in medium-volume production.

High Adaptability: Suitable for casting complex geometries and larger components.

Wide Material Selection: Suitable for a variety of copper alloys, offering significant advantages in medium-volume production.

Sesuai untuk: Medium-volume production and large-size castings, especially for cost-sensitive projects.

Suitable for medium-sized components in industries such as automotive and machinery.

Suitable for medium-sized components in industries such as automotive and machinery.

Recommended components: Gears, pumps, valves, mechanical connectors, ship components, etc.

Pemutus Pelaburan

Applicable copper alloys: electrolytic copper (Cu-ETP), bronze (Cu-Sn), aluminum bronze (Cu-Al), lead bronze (Cu-Sn-Pb)

ciri-ciri: High Precision: Suitable for parts requiring complex shapes and high dimensional accuracy.

Excellent Surface Quality: Investment casting can achieve a high surface finish, reducing the need for subsequent machining.

Material Flexibility: A wide range of copper and its alloys can be cast, including high-strength and high-corrosion-resistant alloys.

Excellent Surface Quality: Investment casting can achieve a high surface finish, reducing the need for subsequent machining.

Material Flexibility: A wide range of copper and its alloys can be cast, including high-strength and high-corrosion-resistant alloys.

Aplikasi: Production of high-precision parts, such as aerospace, high-end automotive components, and precision instruments.

Suitable for casting small batches and complex shapes.

Suitable for casting small batches and complex shapes.

Recommended Components: High-precision electronic contacts, guide rails, springs, marine components, etc.

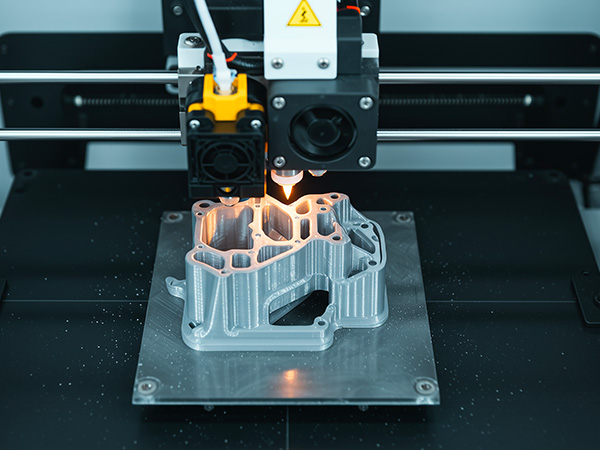

Percetakan 3D

Applicable copper alloys: electrolytic copper (Cu-ETP), aluminum bronze (Cu-Al)

ciri-ciri: Rapid Prototyping: 3D printing is suitable for prototypes and small-batch production, enabling rapid design, adjustment, and optimization.

Complex Geometries: 3D printing can cast complex designs that are difficult to achieve with traditional methods.

High Precision: 3D printing can achieve extremely high geometric accuracy, making it suitable for customization and small-batch production.

Complex Geometries: 3D printing can cast complex designs that are difficult to achieve with traditional methods.

High Precision: 3D printing can achieve extremely high geometric accuracy, making it suitable for customization and small-batch production.

Applicable Scenarios: Small-batch custom production, especially for parts requiring complex shapes or high precision.

High-end manufacturing, scientific research prototype development, aerospace, and electronic equipment.

High-end manufacturing, scientific research prototype development, aerospace, and electronic equipment.

Recommended Parts: Electronic components, complex piping, precision instrument accessories, customized parts, etc.

Kimpalan

Applicable copper alloys: Most copper alloys, such as electrolytic copper (Cu-ETP), bronze (Cu-Sn)

ciri-ciri: Suitable for metal joining: Welding is suitable for processes requiring the joining of dissimilar parts or repairs, and is particularly well-suited for joining large parts.

Lower precision requirements: Welding is not typically used for complex single-part castings, but rather for the joining of multiple parts.

Lower precision requirements: Welding is not typically used for complex single-part castings, but rather for the joining of multiple parts.

Aplikasi: Suitable for mass welding and repair of parts, especially metal structures involving copper alloys.

Suitable for connecting structural components in machinery, construction, energy, and other fields.

Suitable for connecting structural components in machinery, construction, energy, and other fields.

Recommended components:Mechanical structural parts, equipment frames, heat exchanger components, etc.

Mulakan Projek Anda dengan Leierwo

1. Hantar Pertanyaan Anda

Hantar lukisan CAD dan fail 3D anda melalui e-mel, menyatakan gred bahan, kuantiti pesanan, kemasan permukaan atau sebarang butiran lain yang berkaitan.

2. Pengiraan Kos

Sebaik sahaja kami menerima reka bentuk anda, pasukan kejuruteraan kami akan menilai lukisan dengan teliti dan mengira harga berdasarkan kos pengeluaran sebenar secepat mungkin.

3. Mulakan Pengeluaran

Selepas kelulusan harga, pasukan pengeluaran kami akan menyediakan bahan dan menjadualkan pengeluaran dengan segera. Leierwo sentiasa memastikan penghantaran tepat pada masanya.

4. Susun Penghantaran

Selepas pengeluaran selesai, kami akan memberikan butiran pembungkusan dan mengatur penghantaran melalui laut atau udara. Kami menyokong penghantaran global untuk setiap pesanan.

Soalan Lazim

S1. Adakah anda sebuah syarikat perdagangan atau pengilang?

S2. Bolehkah anda memetik berdasarkan lukisan 3D?

S3. Bagaimanakah anda mengendalikan RFQ (Permintaan Sebutharga)?

S4. Apakah masa utama anda yang biasa?

S5. Adakah anda menyediakan sampel? Adakah mereka bebas?

S6. Apakah kaedah pembayaran yang anda terima?

S7. Bagaimanakah anda memastikan kawalan kualiti?

S8. Adakah produk anda disertakan dengan jaminan?

S9. Bagaimana anda melihat hubungan anda dengan pelanggan?