Gray Iron

Gray cast iron is one of the most commonly used cast iron materials. Its graphite exhibits a typical flaky structure, resulting in excellent casting properties, high fluidity, and a low thermal expansion coefficient. Its excellent wear resistance, good vibration damping properties, and high compressive strength make it widely used in machinery manufacturing, the automotive industry, and construction machinery. Its excellent workability and low cost make it an ideal material for a wide range of structural and mechanical components.

In the precision casting industry, gray cast iron, due to its excellent castability and stable mechanical properties, is widely used in the production of castings requiring high precision and strength. It is particularly well-suited for complex shapes and large-scale structural components, capable of withstanding heavy loads and shocks, and performing exceptionally well in long-term operation. Whether it’s a complex precision component or a large-scale structural part, our gray iron castings can be tailored to your specific needs, providing reliable solutions for a variety of high-end applications.

In the precision casting industry, gray cast iron, due to its excellent castability and stable mechanical properties, is widely used in the production of castings requiring high precision and strength. It is particularly well-suited for complex shapes and large-scale structural components, capable of withstanding heavy loads and shocks, and performing exceptionally well in long-term operation. Whether it’s a complex precision component or a large-scale structural part, our gray iron castings can be tailored to your specific needs, providing reliable solutions for a variety of high-end applications.

Common Material Grades of Gray Iron

| Alloy Name | Material Properties | Application Industry | Sample Widget |

| GG25 (EN-GJL-250) | Contains flake graphite, good castability, processability and wear resistance, suitable for parts subjected to greater pressure | Automobile, machinery manufacturing, construction, home appliances | Engine blocks, lathe beds, machine tool guide rails, pump housings, bearing seats, brake discs |

| GG30 (EN-GJL-300) | High tensile strength (300 MPa), good impact toughness and wear resistance, suitable for parts bearing medium loads | Automobiles, heavy machinery, precision casting, pumps and valves | Gearbox housings, pump bodies, engine cylinder heads, mechanical parts, pressure vessels |

| GG35 (EN-GJL-350) | High tensile strength (300 MPa), good impact toughness and wear resistance, suitable for parts bearing medium loads | Engineering machinery, chemical equipment, shipbuilding, precision casting | Turbine housings, marine engine brackets, mining machinery parts, pressure vessels |

| GG40 (EN-GJL-400) | High strength and good wear resistance, suitable for precision casting under high load environment, with good high temperature resistance | Engineering machinery, power generation equipment, petrochemicals, automobile manufacturing | Turbine blades, diesel engine parts, large machinery parts, pipe supports |

| GG50 (EN-GJL-500) | Higher tensile strength (500 MPa), stronger fatigue resistance and impact resistance, suitable for components subjected to higher stress | Automobile, aerospace, machinery and equipment manufacturing, precision casting | Automobile chassis brackets, crane hooks, aircraft engine casings, industrial pump bodies |

| GG60 (EN-GJL-600) | With very high tensile strength and strong wear resistance, it is suitable for high-load components in extreme environments | High-end machinery, engineering equipment, mining machinery, precision casting | High-strength gears, marine engine housings, mining machinery gearboxes, pressure vessels |

| GG70 (EN-GJL-700) | Ultra-high tensile strength (700 MPa), high wear resistance and impact resistance, suitable for heavy equipment components subjected to extremely high pressure | Heavy machinery, metallurgy, and steel industry | Heavy machinery parts, large mining machinery gears, large pump bodies, large pressure vessels |

| GG15 (EN-GJL-150) | Lower strength, but with excellent casting performance and processability, suitable for parts that do not require high strength | Home appliances, auto parts, and instrument manufacturing | Motor housing, home appliance body, low-load mechanical parts |

Gray Iron Casting Process

Sand Casting

Features:

Sand casting is well-suited for gray cast iron production, enabling the rapid and efficient production of complex, large-scale castings. Gray cast iron’s excellent casting properties and stable physical properties make it suitable for the production of large quantities of standardized or customized parts. Sand casting also effectively preserves the advantages of gray cast iron, such as good wear resistance, low cost, and high impact toughness.

Sand casting is well-suited for gray cast iron production, enabling the rapid and efficient production of complex, large-scale castings. Gray cast iron’s excellent casting properties and stable physical properties make it suitable for the production of large quantities of standardized or customized parts. Sand casting also effectively preserves the advantages of gray cast iron, such as good wear resistance, low cost, and high impact toughness.

Applicable Applications:

Medium-to-high strength mechanical components, automotive engine mounts, gearbox housings, hydraulic pump bodies, etc.

Medium-to-high strength mechanical components, automotive engine mounts, gearbox housings, hydraulic pump bodies, etc.

If you’re looking for medium- to high-volume production with complex shapes or large parts, sand casting is the perfect choice. It delivers high strength, excellent wear resistance, and manages production costs, making it suitable for applications in the automotive, machinery, and engineering industries.

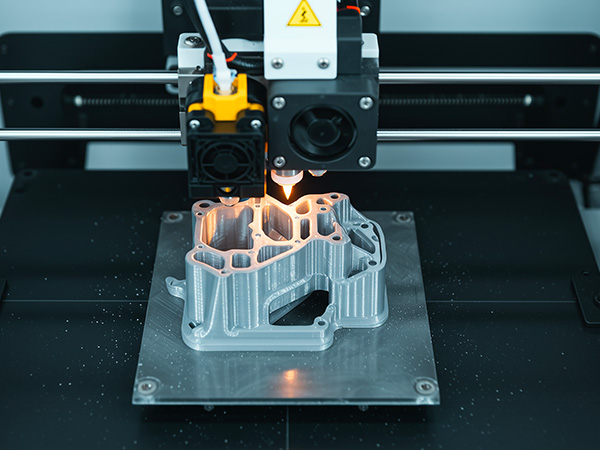

3D Printing

Features:

3D printing technology is suitable for producing complex geometries and small-batch custom parts. Although 3D printing of gray cast iron is somewhat more challenging than with other materials, precision sand mold printing technology can still meet certain customization requirements for gray cast iron, making it particularly suitable for prototyping and rapid, low-volume production. 3D printing is also suitable for producing parts with complex internal structures, avoiding the mold limitations of traditional casting processes.

3D printing technology is suitable for producing complex geometries and small-batch custom parts. Although 3D printing of gray cast iron is somewhat more challenging than with other materials, precision sand mold printing technology can still meet certain customization requirements for gray cast iron, making it particularly suitable for prototyping and rapid, low-volume production. 3D printing is also suitable for producing parts with complex internal structures, avoiding the mold limitations of traditional casting processes.

Suitable for:

Low-volume custom parts, rapid prototyping, and parts with complex shapes or internal channels.

Low-volume custom parts, rapid prototyping, and parts with complex shapes or internal channels.

If you need small-batch production or rapid prototyping, and require parts with complex shapes or special geometries, 3D printing can provide you with an efficient and precise solution. It is particularly suitable for the customized needs of industries such as automotive, aerospace, and industrial equipment.

Start Your Project with Leierwo

1. Submit Your Inquiry

Send your CAD drawings and 3D files via email, specifying material grade, order quantity, surface finish, or any other relevant details.

2. Cost Calculation

Once we receive your design, our engineering team will carefully evaluate the drawings and calculate the price based on actual production costs as soon as possible.

3. Start Production

Upon pricing approval, our production team will prepare the materials and schedule production promptly.Leierwo always ensures on-time delivery.

4. Arrange Delivery

After production is completed, we will provide packaging details and arrange shipment via sea or air. We support global shipping for every order.

FAQ

Q1. Are you a trading company or a manufacturer?

Q2. Can you quote based on 3D drawings?

Q3. How do you handle RFQs (Request for Quotation)?

Q4. What is your typical lead time?

Q5. Do you provide samples? Are they free?

Q6. What payment methods do you accept?

Q7. How do you ensure quality control?

Q8. Do your products come with a warranty?

Q9. How do you view your relationship with customers?