Servicios de fundición a la cera perdida

The use of wax patterns allows investment casting to capture fine details, enabling the production of components with complex features and tight tolerances, often reducing the need for additional machining. This method is particularly suitable for industries requiring precise and durable parts, such as aerospace, automotive, and medical sectors.

Additionally, investment casting is highly flexible, supporting both small-batch and large-scale production. Whether you need prototypes, custom designs, or specialized components, this process ensures consistent quality and reliability, making it a trusted solution for high-performance metal parts tailored to your needs.

ISOCertificado 9001:2015

12K+Fundiciones de precisión producidas mensualmente

40+Diferentes materiales de fundición

50+Países a los que se envía

Our Core Casting Capabilities And Technological Advantages

High-Precision Tolerance Control

High-Quality Surface And Post-Processing

Complex Design Adaptation

Wide Material Coverage

Full-Cycle Customization Support

Advantages of Investment Casting

High Precision

Customization

Smooth Surface Finish

Design Freedom

High-Quality Materials

Wide Size Range

Our Core Casting Capabilities and Technological Advantages

High-Precision Dimensional Control and Tight Tolerance Enforcement

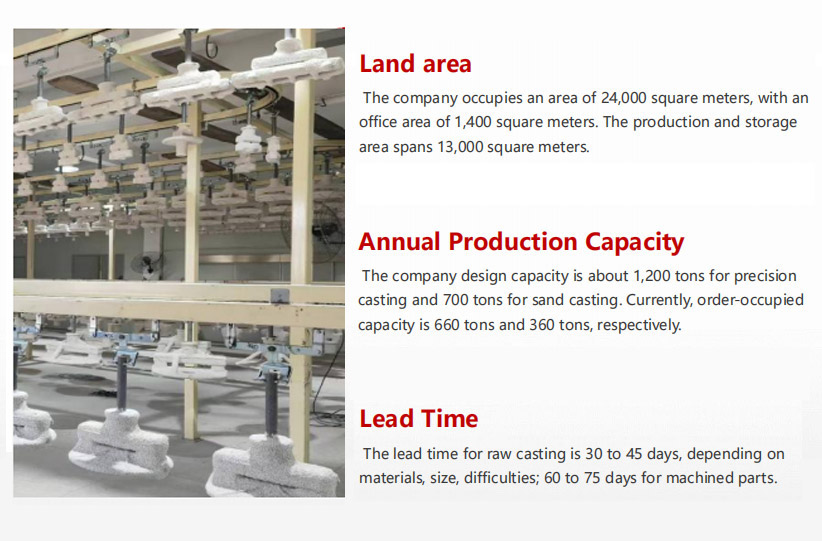

Water Glass Casting: Suitable for customers with medium-to-high precision requirements, it can achieve linear tolerances of ISO 8062 CT7-CT8. It is suitable for applications requiring a high balance between cost and precision, such as excavator bucket teeth, truck components, and agricultural machinery accessories.

Silica Sol Casting: Targeted for applications requiring high precision and surface quality, it can achieve internal diameter tolerances of ISO 8062 CT4-CT6. It is widely used in stainless steel castings, medical device components, and automotive precision structural parts.

Excellent Surface Quality and Post-Processing Optimization

Water glass casting: Achieves an average surface roughness of Ra12.5, suitable for products with moderate aesthetic requirements but prioritized functionality. Silica sol casting: Achieves an excellent surface finish of Ra6.3. In high-end applications, this significantly reduces subsequent polishing, machining, and other processing steps, shortening overall lead times.

Strong Design Adaptability and Complex Structure Casting Capabilities

Wide Range of Material Adaptability

Stainless steel (such as 304, 316, 17-4PH), carbon steel (such as 45 steel, 20# steel), alloy steel (such as 42CrMo, 20CrMnTi), and aluminum alloy (such as ZL101, A356). This material diversity enables us to provide customers with optimal material matching solutions to meet the strength, corrosion resistance, wear resistance, and other performance requirements under different working conditions.

Customized Services and Full-Cycle Technical Support

| Process Type | Dimensional Accuracy (IS0 8062) | Surface Roughness (Ra) | Cost Level | Typical Application Scenarios |

| Fundición de vidrio de agua | CT7-CT8 | 12.5 | Middle | Excavator Parts, Agricultural Machinery, Truck Structural Parts |

| Fundición de sol de sílice | CT4-CT6 | 6.3 | Alto | Medical Equipment, Automotive Precision Parts, Stainless Steel Castings |

Why Choose Investment Casting In Leierwo?

If you have specific product requirements or drawings, please feel free to contact our technical team. We will provide you with professional casting advice and cost optimization solutions.

Opciones personalizables de tratamiento de superficies

Granallado

Mecanizado

Revestimiento de pintura

Recubrimiento en polvo

Revestimiento galvanizado

Revestimiento de óxido negro

Materiales de fundición de inversión

Material Coverage

Complete Technology

Widely Used

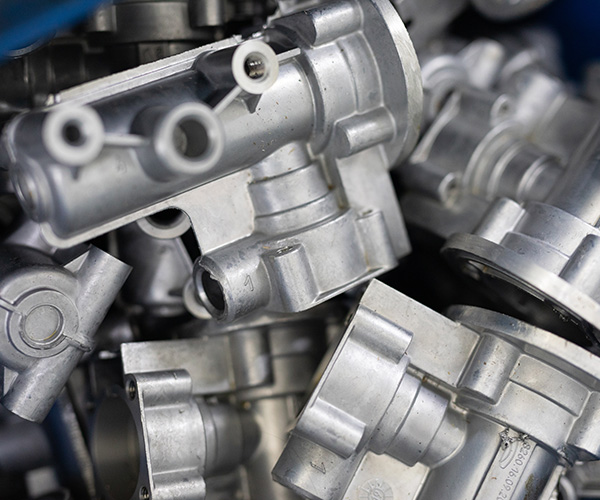

Castings Products

Wax Model Precision Casting

Fundición en arena

Lost Foam Casting

Die Casting and Gravity Casting

Gracias a su excelente durabilidad y resistencia a la corrosión, el acero inoxidable se ha convertido en uno de los materiales más populares en la producción de fundición de precisión. En Leierwo, podemos fundir diversos tipos de acero inoxidable, como acero martensítico, acero ferrítico, acero inoxidable austenítico, acero inoxidable endurecido por precipitación y acero inoxidable dúplex.

Las piezas de acero aleado son piezas fundidas con elementos como molibdeno, manganeso, níquel, cromo, vanadio, silicio y boro. Las piezas de acero aleado fundidas con precisión ofrecen mayor resistencia, dureza, resistencia al desgaste y tenacidad. Los grados típicos de acero aleado para fundición de precisión incluyen AISI 4130, AISI 4140, AISI 8620 y AISI 8630.