Ductile Iron

Ductile iron (DPI) is a cast iron material made by adding a small amount of nodulizer (such as magnesium) to traditional cast iron to transform the graphite structure into a spherical shape. Ductile iron exhibits excellent mechanical and processability. Compared to gray cast iron, it offers higher tensile strength, toughness, wear resistance, and fatigue resistance. Its excellent casting properties enable it to excel in the manufacture of complex castings. Through precise alloying and processing, ductile iron delivers stable performance in diverse operating environments, meeting the demands of various structural and load-bearing components.

In the precision casting industry, ductile iron is widely used in industries such as automotive, construction machinery, and pipeline equipment due to its excellent casting process adaptability and cost-effectiveness. It enables the production of complex, high-precision components through precision casting technology, and exhibits excellent mechanical properties, enabling stable operation under high loads and harsh operating conditions. Whether it’s a complex precision component or a large-scale structural part, our ductile iron castings can be tailored to your specific needs, providing reliable solutions for a variety of high-end applications.

In the precision casting industry, ductile iron is widely used in industries such as automotive, construction machinery, and pipeline equipment due to its excellent casting process adaptability and cost-effectiveness. It enables the production of complex, high-precision components through precision casting technology, and exhibits excellent mechanical properties, enabling stable operation under high loads and harsh operating conditions. Whether it’s a complex precision component or a large-scale structural part, our ductile iron castings can be tailored to your specific needs, providing reliable solutions for a variety of high-end applications.

Common Material Grades of Ductile Iron

| Alloy Name | Material Properties | Application Industry | Sample Widget |

| Ductile Iron (SG Iron) | Excellent strength, toughness, wear resistance, fatigue resistance, good castability, good impact toughness and crack resistance | Automobile, construction machinery, precision casting | Automobile engine cylinder block, gear box housing, brake disc, hydraulic cylinder block |

| QT400-18 | Good tensile strength (400 MPa), impact resistance, and high fatigue strength, suitable for components subjected to greater pressure and impact | Construction machinery, agricultural machinery, precision casting | Excavator parts, agricultural machinery parts, marine engine housings |

| QT450-10 | High tensile strength (450 MPa) and good ductility, suitable for structural parts with medium loads | Automobile, machinery manufacturing, precision casting | Automobile control arms, automobile steering systems, transmission components |

| QT500-7 | High tensile strength and toughness, strong crack resistance, widely used in parts subjected to high stress and impact | Automobile, construction machinery, precision casting, machinery manufacturing | Automobile wheels, flywheels, engine brackets, oil pump housings |

| QT600-3 | With excellent wear resistance and fatigue resistance, good corrosion resistance, suitable for high strength and wear-resistant working conditions | Engineering machinery, chemical industry, mining machinery, precision casting | Large mechanical parts, mining machinery housings, wear-resistant pump bodies, bearing housings |

| QT800-5 | High strength and toughness, excellent corrosion resistance, suitable for the manufacture of high-load and high-impact components | High-end automobile manufacturing, aerospace, precision casting | Aircraft engine casings, large mechanical components, automobile wheels, machine tool beds |

| QT900-3 | Ultra-high strength, suitable for extreme working environments, with good crack resistance and wear resistance | High-intensity application areas, such as wind power, nuclear power, and automotive industry | Wind turbine tower bases, nuclear power pressure vessels, oversized wheels and rotating parts |

| EN-GJS-400-18 | Excellent casting properties, good strength, toughness and fatigue resistance, suitable for casting of conventional industrial parts | Automobile, machinery manufacturing, precision casting | Wind turbine tower bases, nuclear power pressure vessels, oversized wheels and rotating parts |

| EN-GJS-400-18 | High tensile strength and fatigue resistance, suitable for parts requiring greater strength and toughness | Automobiles, machinery and equipment, precision casting | Automobile front and rear axles, suspension systems, and automated mechanical transmission components |

Nickel and Its Alloy Casting Process

Investment Casting

Features:

Sand casting offers high flexibility and is suitable for producing medium- to large-sized ductile iron parts. This process is suitable for larger production runs, offering excellent cost-effectiveness and reliability. It is particularly well-suited for castings with complex shapes that do not require extreme precision. The combination of ductile iron’s excellent castability and sand casting results in castings with excellent mechanical properties and low production costs.

Sand casting offers high flexibility and is suitable for producing medium- to large-sized ductile iron parts. This process is suitable for larger production runs, offering excellent cost-effectiveness and reliability. It is particularly well-suited for castings with complex shapes that do not require extreme precision. The combination of ductile iron’s excellent castability and sand casting results in castings with excellent mechanical properties and low production costs.

Applications:

Suitable for medium-to-high-strength components such as automotive engine mounts, gearbox housings, hydraulic pump bodies, and industrial equipment casings.

Suitable for medium-to-high-strength components such as automotive engine mounts, gearbox housings, hydraulic pump bodies, and industrial equipment casings.

If your needs are to mass-produce ductile iron parts with complex shapes or large sizes, sand casting will be a very suitable choice, which can ensure good strength, toughness and relatively economical production costs.

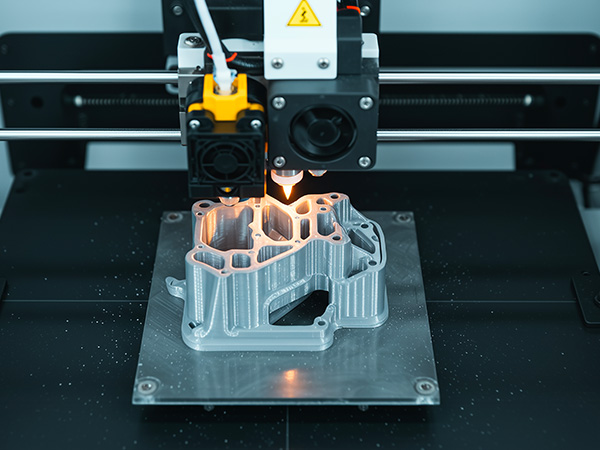

3D Printing

Features:

3D printing can produce complex ductile iron parts, making it particularly suitable for low-volume production and prototyping. While 3D printing of ductile iron is more complex and expensive than other alloys, it still offers a promising solution for prototyping, complex structural geometries, and customized needs.

3D printing can produce complex ductile iron parts, making it particularly suitable for low-volume production and prototyping. While 3D printing of ductile iron is more complex and expensive than other alloys, it still offers a promising solution for prototyping, complex structural geometries, and customized needs.

Suitable for:

Small-batch custom parts, rapid prototyping, and complex industrial parts.

Small-batch custom parts, rapid prototyping, and complex industrial parts.

If your needs are small-batch production or rapid prototyping, 3D printing can quickly produce complex-shaped ductile iron parts, which is particularly suitable for customized needs in engineering machinery, automotive industry and other fields.

Start Your Project with Leierwo

1. Submit Your Inquiry

Send your CAD drawings and 3D files via email, specifying material grade, order quantity, surface finish, or any other relevant details.

2. Cost Calculation

Once we receive your design, our engineering team will carefully evaluate the drawings and calculate the price based on actual production costs as soon as possible.

3. Start Production

Upon pricing approval, our production team will prepare the materials and schedule production promptly.Leierwo always ensures on-time delivery.

4. Arrange Delivery

After production is completed, we will provide packaging details and arrange shipment via sea or air. We support global shipping for every order.

FAQ

Q1. Are you a trading company or a manufacturer?

Q2. Can you quote based on 3D drawings?

Q3. How do you handle RFQs (Request for Quotation)?

Q4. What is your typical lead time?

Q5. Do you provide samples? Are they free?

Q6. What payment methods do you accept?

Q7. How do you ensure quality control?

Q8. Do your products come with a warranty?

Q9. How do you view your relationship with customers?