Zinc and Its Alloys

Zinc and its alloys are commonly used in precision casting, characterized by good fluidity, a low melting point, and excellent corrosion resistance. Zinc alloys enable precise filling of complex molds during the casting process, making them suitable for parts requiring high precision and excellent surface quality. Zinc alloys are widely used in the electronics, automotive, and consumer goods industries, often in the manufacture of housings, connectors, and auto parts.

In precision casting, zinc alloys are primarily used in die casting and investment casting processes, offering high precision and high production efficiency. Their low melting point helps reduce production costs, and their excellent surface finish properties give them significant advantages in high-volume production.

In precision casting, zinc alloys are primarily used in die casting and investment casting processes, offering high precision and high production efficiency. Their low melting point helps reduce production costs, and their excellent surface finish properties give them significant advantages in high-volume production.

Common Material Grades of Zinc And Its Alloys

| Alloy Grade | Alloy Name | Material Properties | Main Application Industries | Sample Widget |

| ZL2 | Zl2 Alloy | Excellent castability, good strength and hardness, good corrosion resistance | Automobile, electronics, electrical, precision casting | Electronic component housings, auto parts |

| ZL3 | Zl3 Alloy | Excellent castability and good mechanical properties with medium strength | Precision casting, electronic device manufacturing | Precision gears and mechanical parts |

| ZL5 | Zl5 Alloy | High strength, strong wear resistance and good corrosion resistance | Aerospace, automotive parts | High-strength frames, automobile engine casings |

| ZL8 | Zl8 Alloy | Low casting temperature, good fluidity and surface finish | Precision casting, automobiles, electronics | Precision casting of power tool housings and transmission system components |

| ZA8 | ZA8 Alloy | High strength, good corrosion resistance, suitable for high pressure casting | Automotive, electrical, aerospace | Electronic connectors, high-pressure casting parts |

| ZL27 | Zl27 Alloy | Excellent strength, corrosion resistance and wear resistance | Aerospace, automotive | High-strength automobile engine parts |

| ZD9 | ZD9 Alloy | Excellent corrosion resistance and strength, good heat treatment | Marine engineering, precision casting | Ship parts, marine equipment housings |

| ZD8 | ZD8 Alloy | Good casting properties, high tensile strength and ductility | Precision casting, electronics, instruments | Electronic product housings, medical equipment components |

| ZL13 | Zl13 Alloy | Good castability and corrosion resistance, high strength and hardness | Aerospace, automotive, precision casting | Aviation parts, automotive precision casting parts |

Zinc and Its Alloy Casting Process

Investment Casting

Applicability: Suitable for casting zinc and its alloys, but is generally used for precision castings, especially when high precision and complex geometry are required. Investment casting can achieve very detailed designs, including complex internal cavities and precise surface finishes.

Advantages:

· High-precision, low-volume products: Small precision parts in the aviation, automotive, and medical device industries.

· Excellent surface finish: Suitable for zinc alloy parts with complex shapes, thin walls, and high wear resistance.

· Rapid development and customization: Customized products requiring fast delivery.

· High-precision, low-volume products: Small precision parts in the aviation, automotive, and medical device industries.

· Excellent surface finish: Suitable for zinc alloy parts with complex shapes, thin walls, and high wear resistance.

· Rapid development and customization: Customized products requiring fast delivery.

Sand Casting

Applicability: Sand casting is a traditional and widely used casting process suitable for zinc alloy casting, especially in the production of larger castings. Sand casting molds are relatively low cost, suitable for small or medium batch production, and can produce larger castings.

Advantages:

· Medium-sized, non-precision castings: Suitable for larger, simple-shaped parts such as automotive components and electrical enclosures.

· Lower costs: Suitable for high-volume production where cost-effective products are required, especially in high-volume production.

· Medium-sized, non-precision castings: Suitable for larger, simple-shaped parts such as automotive components and electrical enclosures.

· Lower costs: Suitable for high-volume production where cost-effective products are required, especially in high-volume production.

Die Casting

Applicability: Die casting is very suitable for the efficient large-scale production of zinc and its alloys, especially for the mass production of high-precision and thin-walled castings. Zinc alloys have excellent fluidity and low melting points during the die casting process, making them very suitable for the rapid production of high-quality castings.

Advantages:

· Large-Scale Production and Precision Castings: Suitable for mass production of high-precision, complex-shaped castings, such as electronic device housings, home appliance components, and automotive parts.

· High Production Efficiency: Suitable for industries with demanding lead times, such as consumer electronics, automotive, and industrial equipment.

· Large-Scale Production and Precision Castings: Suitable for mass production of high-precision, complex-shaped castings, such as electronic device housings, home appliance components, and automotive parts.

· High Production Efficiency: Suitable for industries with demanding lead times, such as consumer electronics, automotive, and industrial equipment.

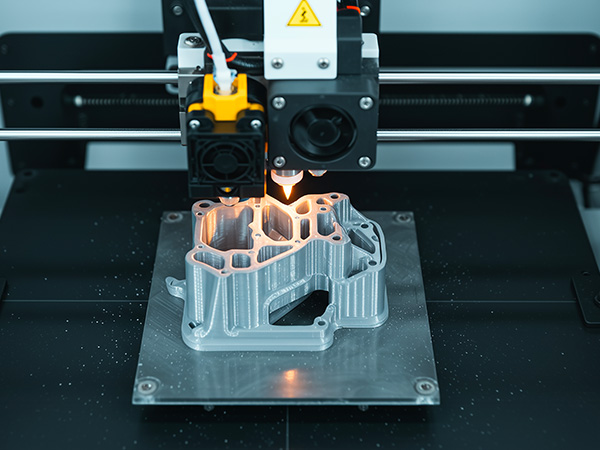

3D Printing

Applicability: 3D printing technology is suitable for small-batch, high-complexity, and rapidly developed castings, and is particularly suitable for customization and prototyping. Although 3D printing casting is still in its development stage, in some cases, it can be used to produce complex zinc alloy parts.

Advantages:

· Small-batch customization and rapid prototyping: Zinc alloy parts that require rapid production, such as prototype testing and design verification.

· Complex shapes and innovative designs: These applications require complex castings, especially those requiring rapid modification and verification during the design phase.

· Small-batch customization and rapid prototyping: Zinc alloy parts that require rapid production, such as prototype testing and design verification.

· Complex shapes and innovative designs: These applications require complex castings, especially those requiring rapid modification and verification during the design phase.

Start Your Project with Leierwo

1. Submit Your Inquiry

Send your CAD drawings and 3D files via email, specifying material grade, order quantity, surface finish, or any other relevant details.

2. Cost Calculation

Once we receive your design, our engineering team will carefully evaluate the drawings and calculate the price based on actual production costs as soon as possible.

3. Start Production

Upon pricing approval, our production team will prepare the materials and schedule production promptly.Leierwo always ensures on-time delivery.

4. Arrange Delivery

After production is completed, we will provide packaging details and arrange shipment via sea or air. We support global shipping for every order.

FAQ

Q1. Are you a trading company or a manufacturer?

Q2. Can you quote based on 3D drawings?

Q3. How do you handle RFQs (Request for Quotation)?

Q4. What is your typical lead time?

Q5. Do you provide samples? Are they free?

Q6. What payment methods do you accept?

Q7. How do you ensure quality control?

Q8. Do your products come with a warranty?

Q9. How do you view your relationship with customers?