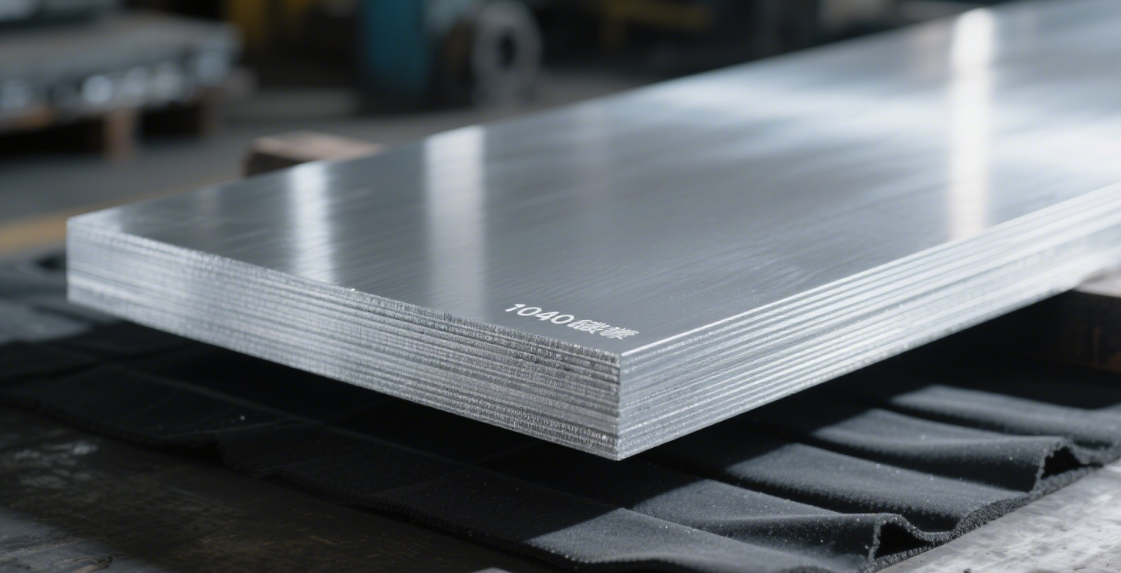

Apakah Keluli Karbon 1040? Panduan Komprehensif

Dalam dunia keluli karbon yang luas, 1040 Keluli Karbon menonjol sebagai bahan yang serba boleh dan digunakan secara meluas, terutamanya dalam aplikasi mekanikal dan perindustrian. Dikenali dengan keseimbangan kekuatan, kekerasan dan kebolehmesinan yang sangat baik, aloi keluli karbon sederhana ini adalah pilihan utama untuk jurutera, pengilang dan ahli metalurgi.

Panduan komprehensif ini bertujuan untuk memberikan pemahaman yang mendalam tentang 1040 Keluli Karbon, meneroka komposisi kimianya, sifat mekanikal, aplikasi, pilihan rawatan haba dan kelebihan dalam proses penuangan atau penempaan. Sama ada anda seorang jurutera mekanikal, saintis bahan atau seseorang yang berminat dalam proses pembuatan, artikel ini akan menawarkan pandangan berharga tentang ciri dan kegunaan 1040 Keluli Karbon.

Jadual Kandungan

pengenalan

1040 Keluli Karbon ialah gred keluli karbon sederhana yang tergolong dalam siri 10xx keluli karbon biasa. "10" pada permulaan menunjukkan ia adalah keluli karbon biasa tanpa sebarang unsur pengaloian yang ketara, manakala "40" merujuk kepada anggaran kandungan karbon — kira-kira 0.40% mengikut berat.

Kandungan karbon ini menempatkan 1040 Keluli Karbon dalam julat karbon sederhana, yang bermaksud ia menawarkan keseimbangan antara kemuluran dan kekuatan. Ia boleh dirawat haba untuk meningkatkan sifat mekanikalnya, menjadikannya sesuai untuk pelbagai aplikasi kejuruteraan.

Tidak seperti keluli karbon rendah yang mudah dibentuk tetapi kurang kekuatan, atau keluli karbon tinggi yang keras tetapi rapuh, 1040 Keluli Karbon mencapai keseimbangan. Ia biasanya digunakan dalam pengeluaran bahagian mekanikal seperti gandar, gear, aci engkol, dan rod penyambung.

Komposisi Kimia dan Sifat Mekanikal 1040 Keluli Karbon

Komposisi Kimia

| unsur | Komposisi (%) |

|---|---|

| Karbon (C) | 0.37 – 0.44 |

| Mangan (Mn) | 0.60 – 0.90 |

| Fosforus (P) | ≤ 0.04 |

| Sulfur (S) | ≤ 0.05 |

| Silikon (Si) | 0.15 – 0.35 |

| Besi (Fe) | Baki |

Kehadiran mangan dalam 1040 Keluli Karbon meningkatkan kekuatan dan rintangan hausnya, sementara juga meningkatkan kebolehkerjaan panas. Silikon menyumbang kepada penyahoksidaan semasa proses pembuatan keluli dan sedikit meningkatkan kekuatan.

Sifat Mekanikal

| Harta benda | Nilai |

|---|---|

| Kekuatan Tegangan | 620 – 850 MPa |

| Kekuatan Hasil | 410 – 750 MPa |

| Pemanjangan pada Waktu Rehat | 20 – 25% |

| Kekerasan (Brinell) | 170 – 210 HB |

| Ketumpatan | 7.85 g/cm³ |

| Modulus Keanjalan | 200 GPa |

Sifat-sifat ini membuat 1040 Keluli Karbon sesuai untuk bahagian yang memerlukan kekuatan sederhana dan rintangan haus. Ia juga mengekalkan keliatan yang baik dan rintangan keletihan, terutamanya apabila dirawat haba dengan betul.

Aplikasi Keluli Karbon 1040

Gabungan unik kekuatan, kemuluran, dan kebolehmesinan membuat 1040 Keluli Karbon pilihan popular dalam banyak industri. Berikut adalah beberapa aplikasi yang paling biasa:

Komponen Automotif

Salah satu aplikasi utama keluli karbon 1040 adalah dalam industri automotif. Kekuatan dan kebolehmesinan menjadikannya sesuai untuk pembuatan bahagian seperti:

- gandar

- Gear

- Batang penyambung

- Aci engkol

- Komponen stereng

Bahagian ini memerlukan bahan yang boleh menahan tekanan dan keletihan yang tinggi sambil kos efektif dan mudah dimesin. Keluli 1040 boleh dirawat haba (cth, pelindapkejutan dan pembajaan) untuk meningkatkan kekerasan permukaan dan rintangan haus, yang penting untuk menggerakkan bahagian mekanikal.

Bahagian Struktur dan Jentera

Oleh kerana kekuatannya yang sederhana dan kebolehkimpalan yang baik, keluli 1040 biasanya digunakan dalam aplikasi struktur dan jentera am:

- Aci dan gelendong

- Sesendal dan pin

- Bingkai dan tapak mesin

- Struktur sokongan dalam peralatan perindustrian

Ia sering dipilih berbanding keluli karbon rendah apabila kekuatan yang lebih tinggi diperlukan tanpa peningkatan kos atau kerapuhan yang berkaitan dengan keluli karbon tinggi.

Peralatan Pertanian dan Pembinaan

Dalam peralatan yang digunakan dalam pertanian dan pembinaan, bahagian selalunya tertakluk kepada haus, kesan dan pendedahan alam sekitar. Keluli 1040 digunakan untuk membuat:

- bilah bajak

- Rod silinder hidraulik

- Himpitan treler

- Lengan pemuat dan kurungan

Aplikasi ini mendapat manfaat daripada keupayaan bahan untuk dirawat haba untuk kekerasan permukaan sambil mengekalkan teras yang kuat untuk menyerap hentakan.

Fabrikasi Tersuai dan Alat Ganti

Kerana kemudahan pemesinan dan kimpalannya, keluli karbon 1040 sering digunakan dalam aplikasi pembuatan dan pembaikan tersuai:

- Alat ganti untuk jentera perindustrian

- Aci dan sesendal tersuai

- Komponen prototaip

Fleksibilitinya menjadikannya bahan pilihan untuk operasi pengeluaran dan penyelenggaraan berskala kecil di mana aloi volum tinggi mungkin tidak menjimatkan kos.

Rawatan Haba dan Kebolehmesinan 1040 Keluli Karbon

1040 Keluli Karbon, yang terkenal dengan sifat mekanikalnya yang seimbang, sangat digemari dalam pelbagai aplikasi perindustrian kerana keupayaannya untuk bertindak balas dengan baik kepada rawatan haba. Rawatan haba meningkatkan kekuatan, kekerasan dan prestasi keseluruhannya dengan ketara, menjadikannya sesuai untuk pelbagai bahagian dan komponen. Di bawah, kami menyelidiki lebih mendalam proses rawatan haba yang berbeza, serta ciri kebolehmesinan 1040 Keluli Karbon.

Penyepuhlindapan

Penyepuhlindapan adalah proses yang digunakan untuk melembutkan 1040 Keluli Karbon, menjadikannya lebih mudah untuk dimesin, dibentuk atau dikimpal. Suhu penyepuhlindapan biasa untuk keluli ini adalah sekitar 870°C (1600°F). Keluli dipegang pada suhu ini untuk tempoh tertentu untuk membolehkan tegasan dalaman hilang. Selepas itu, ia disejukkan perlahan-lahan dalam relau atau udara, yang membantu menapis struktur butirannya, meningkatkan kemulurannya dan meningkatkan kebolehkerjaan keseluruhannya.

Faedah Penyepuhlindapan:

- Kebolehkerjaan yang dipertingkatkan: Melembutkan keluli untuk pemesinan yang lebih mudah atau pemprosesan selanjutnya.

- Melegakan Tekanan: Mengurangkan tegasan sisa yang mungkin telah diperkenalkan semasa langkah pembuatan sebelumnya.

- Sifat Membentuk Lebih Baik: Memudahkan pembentukan keluli ke dalam bentuk yang diingini, terutamanya apabila digunakan dalam aplikasi seperti penempaan atau pengecapan.

Menormalkan

Menormalkan adalah satu lagi proses rawatan haba di mana 1040 Keluli Karbon dipanaskan kepada sekitar 890°C (1630°F), kemudian disejukkan dengan udara. Proses ini memperhalusi struktur bijian keluli, menambah baik sifat mekanikal dan menjadikan bahan lebih seragam dari segi kekuatan dan kekerasan. Matlamat utama menormalkan adalah untuk menghapuskan sebarang tekanan dalaman dan memastikan prestasi bahan yang lebih konsisten.

Faedah Menormalkan:

- Struktur Bijian Halus: Membantu dalam meningkatkan sifat mekanikal keseluruhan seperti kekuatan, keliatan dan kekerasan.

- Peningkatan Kekuatan dan Ketangguhan: Meningkatkan keupayaan bahan untuk menahan tekanan mekanikal, menjadikannya sesuai untuk komponen galas beban.

- Kebolehkerjaan yang Dipertingkatkan untuk Proses Seterusnya: Dengan menapis bahan, menormalkan menjadikannya lebih mudah untuk digunakan semasa pemesinan, kimpalan atau pembentukan.

Pengerasan dan Pembajaan

Pengerasan dan pembajaan adalah proses utama yang digunakan untuk meningkatkan kekerasan dan kekuatan 1040 Keluli Karbon, menjadikannya lebih sesuai untuk aplikasi tekanan tinggi. Pengerasan melibatkan pemanasan keluli kepada kira-kira 840–870°C (1540–1600°F) dan kemudian menyejukkannya dengan cepat dengan pelindapkejutan dalam air atau minyak. Penyejukan pantas mengunci struktur dalaman keluli ke dalam keadaan keras. Selepas itu, keluli dibaja pada suhu antara 400–600°C (750–1100°F) untuk mengurangkan kerapuhan dan mencapai keseimbangan kekerasan dan keliatan yang diingini.

Faedah Pengerasan dan Pembajaan:

- Kekerasan yang Dipertingkatkan dan Rintangan Haus: Proses ini meningkatkan keupayaan keluli untuk menahan haus dan lusuh, menjadikannya sesuai untuk komponen yang akan mengalami geseran tinggi atau keadaan melelas.

- Ketangguhan yang dipertingkatkan: Pembajaan memastikan keluli kekal keras, mengelakkan keretakan atau pecah di bawah tekanan.

- Peningkatan Ketahanan Keletihan: Gabungan pengerasan dan pembajaan juga meningkatkan keupayaan bahan untuk menahan kitaran tegasan berulang, penting untuk bahagian yang mengalami beban keletihan.

Kebolehmesinan

Dengan penarafan kebolehmesinan sekitar 60% daripada keluli AISI 1212 standard, 1040 Keluli Karbon agak mudah untuk dimesin, terutamanya dalam keadaan normal atau anil. Ia bertindak balas dengan baik terhadap operasi pemotongan, penggerudian dan pemutaran.

Kelebihan Keluli Karbon 1040 dalam Tuangan dan Penempaan

1040 Keluli Karbon dianggap agak mudah untuk dimesin, terutamanya apabila ia berada dalam keadaan normal atau anil. Dengan penarafan kebolehmesinan sekitar 60% daripada keluli AISI 1212 standard, ia bertindak balas dengan baik kepada operasi pemesinan biasa seperti memotong, menggerudi dan memusing. Kebolehmesinan 1040 dipertingkatkan lagi apabila ia telah dirawat haba dengan betul, membolehkan proses pemesinan yang lebih lancar dan cekap.

Faedah Kebolehmesinan:

- Lebih mudah untuk dimesin dalam Keadaan Annealed/Normal: Struktur yang lebih lembut dan seragam menjadikannya lebih mudah untuk dimesin dengan alat standard.

- Kemasan Permukaan yang Baik: Proses pemesinan yang betul boleh menghasilkan kemasan permukaan berkualiti tinggi, menjadikannya sesuai untuk komponen ketepatan.

- Kos-Efektif: Terima kasih kepada kebolehmesinan yang baik, 1040 Keluli Karbon boleh diproses dengan alat pemotong dan mesin standard, mengurangkan kos pengeluaran keseluruhan.

Faedah Penempaan

- Kemuluran dan Kekuatan Tinggi: Membolehkan pembentukan kompleks tanpa retak.

- Ciri Aliran Baik: Memastikan struktur butiran dan sifat mekanikal yang konsisten.

- Respons Cemerlang terhadap Rawatan Haba: Meningkatkan ketahanan haus dan hayat keletihan.

Bahagian palsu diperbuat daripada 1040 Keluli Karbon lazimnya terdapat dalam komponen automotif dan aeroangkasa di mana kebolehpercayaan dan jangka hayat adalah kritikal.

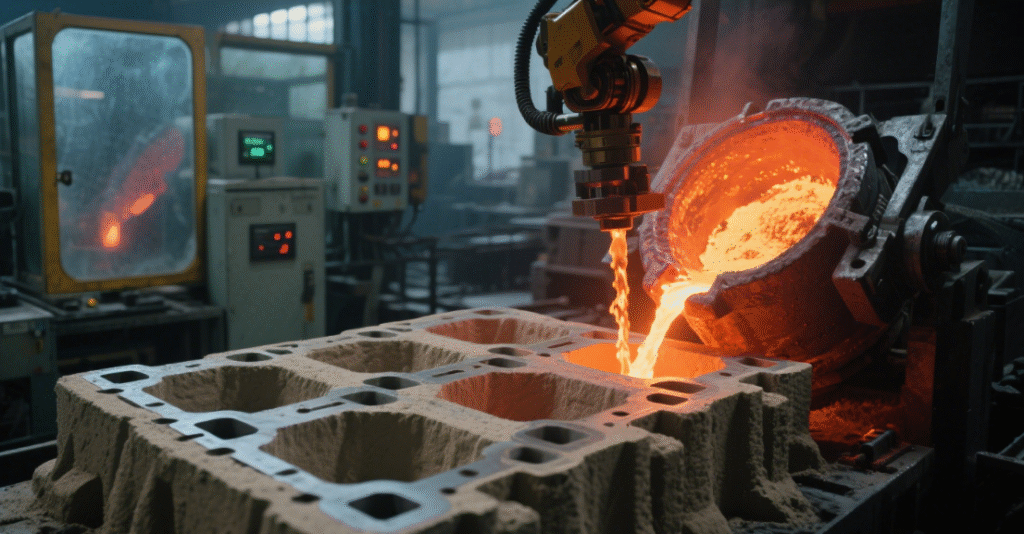

Faedah Pemutus

- Kos Lebih Rendah untuk Bentuk Kompleks: Tuangan membolehkan pengeluaran bahagian yang rumit tanpa pemesinan yang mahal.

- Kestabilan Dimensi yang Baik: Mengekalkan bentuk dan saiz selepas disejukkan.

- Struktur Mikro Seragam: Membawa kepada tingkah laku mekanikal yang boleh diramal.

Dalam pemutus, 1040 Keluli Karbon boleh digunakan untuk menghasilkan komponen yang besar dan kompleks yang sukar untuk dihasilkan melalui kaedah lain.

Perbandingan Keluli 1040 dengan Gred Keluli Lain

| Harta benda | 1020 Keluli | 1040 Keluli | 1060 Keluli |

|---|---|---|---|

| Kandungan Karbon | 0.18 – 0.25% | 0.37 – 0.44% | 0.55 – 0.65% |

| kekuatan | rendah | Sederhana | tinggi |

| Ductility | tinggi | Sederhana | rendah |

| Rintangan Haus | rendah | Medium-High | tinggi |

| Kebolehmesinan | Cemerlang | bagus | Adil |

| Penggunaan Biasa | Komponen Struktur | Shafts, Gears | Springs, Blades |

This comparison highlights the versatility of 1040 Keluli Karbon — it offers a good compromise between strength and machinability, making it suitable for a wide range of applications.

Soalan Lazim

1. What is 1040 Carbon Steel used for?

1040 Keluli Karbon is commonly used in the manufacture of crankshafts, gears, axles, connecting rods, and other mechanical parts that require moderate strength and wear resistance.

2. Is 1040 Keluli Karbon weldable?

ya, 1040 Keluli Karbon can be welded, though preheating and post-weld heat treatment are often recommended to prevent cracking and maintain mechanical properties.

3. Can 1040 Carbon Steel be hardened?

ya, 1040 Keluli Karbon responds well to heat treatment. It can be hardened through quenching and tempering, which significantly increases its surface hardness and strength.

4. What is the difference between 1040 and 4140 steel?

While 1040 Keluli Karbon is a plain carbon steel, 4140 Steel is an alloy steel containing chromium and molybdenum. This gives 4140 superior toughness and strength, especially at elevated temperatures.

5. Is 1040 Keluli Karbon suitable for casting?

ya, 1040 Keluli Karbon is suitable for casting, especially for large or complex components. Its good flowability and dimensional stability make it ideal for cast applications.

6. Does 1040 Carbon Steel rust?

Like all carbon steels, 1040 Keluli Karbon is susceptible to rust and corrosion when exposed to moisture and oxygen. Protective coatings or plating are recommended for outdoor or corrosive environments.

Kesimpulan

1040 Keluli Karbon offers a compelling combination of strength, ductility, and machinability, making it a preferred material across various industries. Whether you’re designing automotive components, industrial machinery, or durable mechanical parts, 1040 Keluli Karbon provides a reliable and cost-effective solution.

Its ability to be heat-treated, forged, and even cast further enhances its versatility. While it may not be the strongest or hardest steel available, its balanced properties ensure that it remains a staple in modern engineering and manufacturing.

As industries continue to evolve and demand more from materials, 1040 Keluli Karbon remains a trusted choice — a testament to its enduring value in mechanical design and industrial applications.

Kekal Berhubung dengan Kami

Terima kasih kerana membaca! Kami berharap blog ini memberi anda pandangan dan inspirasi yang berharga mengenai siling panel akustik. Jika anda menikmati kandungan tersebut dan ingin sentiasa dikemas kini dengan aliran terkini, petua dan kemas kini di sebalik tabir, kami ingin berhubung dengan anda di media sosial.

📘 Ikuti kami di Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Sertai komuniti kami yang semakin berkembang di mana kami berkongsi nasihat pakar, sorotan produk dan perbincangan interaktif dengan profesional dan peminat reka bentuk dari seluruh dunia.

Mari teruskan perbualan—jumpa anda di sana!

Kategori Produk

- Bahagian Injap

- Bahagian Pam Air

- Bahagian Kotak Galas

- Bahagian Die Casting

- Produk Pam Keluli Tahan Karat

- Produk Pam Besi Tuang

- Bahagian Injap Untuk Kegunaan Kereta

- Bahagian Kenderaan

- Bahagian Injap Untuk Kegunaan Awam

- Bahagian Pam Vakum KF