Shanghai Leierwo:

One-Stop Precision Manufacturing Services and Solutions

Explore our diverse range of efficient manufacturing technologies to meet the needs of various industries, providing solutions from small batches to large-scale production.

We offer comprehensive manufacturing services, including investment casting, sand casting, die casting, 3D printing, and other technologies, to meet customers’ requirements at varying production scales and demands. Whether it’s small-batch customization or large-scale assembly line production, we can provide precise and efficient solutions.

Pemutus Pelaburan

High-precision investment casting technology is suitable for small-batch, high-complexity metal parts.

Tuangan Pasir

Efficient high-volume sand casting, suitable for rapid production of a variety of metal materials.

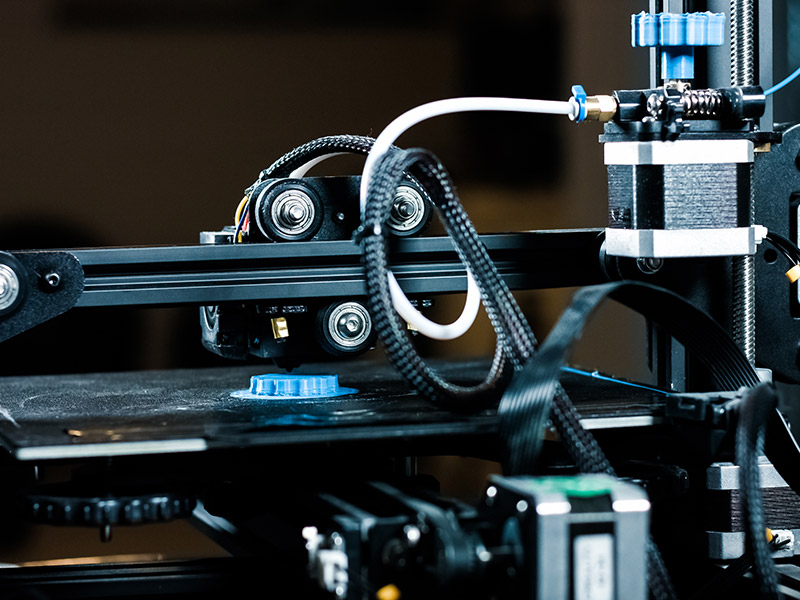

Percetakan 3D

Innovative 3D printing technology for rapid prototyping and small batch custom parts.

Die Casting

Highly efficient die-casting production lines, suitable for large-scale production of high-precision parts.

Kimpalan

Precision welding services are suitable for joining various metal materials.

Menempa

High-strength and durable forging services suitable for a variety of industrial applications.

Start Your Project Now

Whether you need product details, pricing, or expert advice, we’re committed to providing efficient support. Send us your CAD drawings and 3D files for a free quote!

We specialize in providing one-stop precision casting processing services from “demand analysis – drawing optimization – customized production – after-sales tracking” to customers in the fields of petrochemicals, new energy, metal castings, etc. We solve the problem of poor adaptability of standard castings under special working conditions (such as high temperature, high pressure, and severe corrosion). We can customize casting products with different materials, sizes and surface treatment processes according to customer drawings.

Demand Docking:

Receive customer drawings and working conditions requirements, and work with the technical team to analyze material selection and structural feasibility.

Drawing Optimization:

Based on the characteristics of the casting process, optimize the casting wall thickness, fillet and other structures (to avoid shrinkage holes and crack risks), and issue optimized version drawings for confirmation.

Mold Making:

We manufacture custom molds (wax molds/sand molds) according to the confirmed drawings, complete the mold trial and size calibration.

Casting Production:

The blank is produced by investment casting or sand casting technology, and the process includes key steps such as wax model making, shell making, roasting, and casting.

Heat Treatment and Finishing:

According to the material requirements, heat treatment such as solid solution and tempering is carried out, and then precision processing is completed by CNC machine tools, drilling machines and other equipment.

Full Inspection and Delivery:

After passing the full inspection including spectral analysis, non-destructive testing (PT/UT), dimensional measurement, etc., the products will be packaged and delivered.

| Core Dimensions | Features and Advantages | Specific Support Points |

| Degree of Customization | Full Parameter Customization | Adaptable to multiple standard materials such as ASTM/AISI/EN, and supports precision size customization with a minimum tolerance of ±0.05mm |

| Technical Support | Mature Technology | Possess TUV certified welding technology, and key processes (such as casting and heat treatment) are operated by technicians with more than 10 years of experience |

| Quality Stability | Full Process Quality Control | From raw material spectral testing to finished product non-destructive testing, there are 8 quality control nodes, with a pass rate of 99.5% |

| Cost Advantage | Batch Cost Reduction | When the custom order volume exceeds 500 pieces, the unit cost can be reduced by 12%-15% (based on centralized raw material procurement and process optimization) |

Capacity/Delivery: 20-30 orders per month, 30-40 days for simple items, 45-60 days for complex items.

Leierwo Professional Casting Service

Pump Component Manufacturing Analysis

At Leierwo, we are dedicated to providing high-precision casting solutions for various industries.

The fluid dynamics of pump components (such as impellers and pump bodies) directly depend on casting accuracy and surface quality.

High-quality casting not only ensures mechanical strength but also significantly improves pump efficiency and stability.

The following is an analysis of Leierwo’s service options for pump components in just one industry, to help you gain a deeper understanding of our process advantages.

The fluid dynamics of pump components (such as impellers and pump bodies) directly depend on casting accuracy and surface quality.

High-quality casting not only ensures mechanical strength but also significantly improves pump efficiency and stability.

The following is an analysis of Leierwo’s service options for pump components in just one industry, to help you gain a deeper understanding of our process advantages.

Investment Casting – The First Choice for Precision Flow Path Components

The impeller is the “heart” of the pump, and the blade curve must strictly conform to the fluid dynamics design.

Relvuo uses investment casting to achieve:

Dimensional accuracy of ±0.1 mm

Surface finish Ra 3.2 μm or less

Precision impeller casting reduces fluid resistance, improves pump efficiency, and extends service life.

Relvuo uses investment casting to achieve:

Dimensional accuracy of ±0.1 mm

Surface finish Ra 3.2 μm or less

Precision impeller casting reduces fluid resistance, improves pump efficiency, and extends service life.

Sand Casting – Batch Pump Bodies And Structural Parts

The pump body, serving as the support structure and carrier of the fluid passages, has a relatively regular shape (cylindrical or square).

Reilvo uses sand casting to achieve:

Cost-effective mass production

Stable dimensions and structural strength

Meeting the basic requirements of “structural support + fluid passages”

This process balances cost and reliability, making it an ideal choice for essential parts such as pump bodies.

Reilvo uses sand casting to achieve:

Cost-effective mass production

Stable dimensions and structural strength

Meeting the basic requirements of “structural support + fluid passages”

This process balances cost and reliability, making it an ideal choice for essential parts such as pump bodies.

Cnc Finishing – Ensuring Transmission And Sealing Accuracy

After casting, Leerwo uses high-precision CNC machining to refine key areas:

Pump shaft and impeller connection: Concentricity ≤ 0.01 mm

Pump body and end cover sealing surfaces: Ensure flatness and sealing performance

Bearing seat and mounting holes: Ensure assembly accuracy and long-term stability

The combination of casting and CNC machining ensures that the product meets industrial standards for fluid performance, structural strength, and sealing reliability.

Pump shaft and impeller connection: Concentricity ≤ 0.01 mm

Pump body and end cover sealing surfaces: Ensure flatness and sealing performance

Bearing seat and mounting holes: Ensure assembly accuracy and long-term stability

The combination of casting and CNC machining ensures that the product meets industrial standards for fluid performance, structural strength, and sealing reliability.

Comprehensive Advantages

Through a rational combination of investment casting, sand casting, and CNC machining, Leerwo provides pump components with:

High-precision complex flow channel molding

Excellent surface quality and fluid performance

Stable structural strength and sealing reliability

Efficient and economical mass production capabilities

High-precision complex flow channel molding

Excellent surface quality and fluid performance

Stable structural strength and sealing reliability

Efficient and economical mass production capabilities

This is just one example of the many industry service options available to us at LRVO.

Whether your industry requires high-precision pump component castings or other custom castings, LRVO can provide customized, precise, and reliable casting solutions tailored to your equipment needs and operating conditions.

Whether your industry requires high-precision pump component castings or other custom castings, LRVO can provide customized, precise, and reliable casting solutions tailored to your equipment needs and operating conditions.

Soalan Lazim

Q1. Can you provide samples?

Q2. What should I do if it doesn’t match the drawing?