Menempa

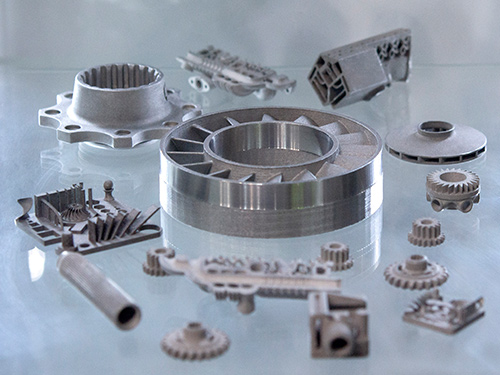

Perkhidmatan pengeluaran besar-besaran penempaan Shanghai Leierwo disesuaikan untuk pelanggan yang mengejar sifat mekanikal yang sangat baik, kekuatan ultra tinggi dan ketahanan.

Proses penempaan menggunakan tekanan yang besar untuk mengubah bentuk kosong logam secara plastik, bukannya mencairkannya. Ini membolehkan gentian dalaman logam untuk diselaraskan secara berterusan di sepanjang arah tegasan utama, menghasilkan bahagian dengan kekuatan, rintangan hentaman dan hayat lesu yang jauh melebihi tuangan.

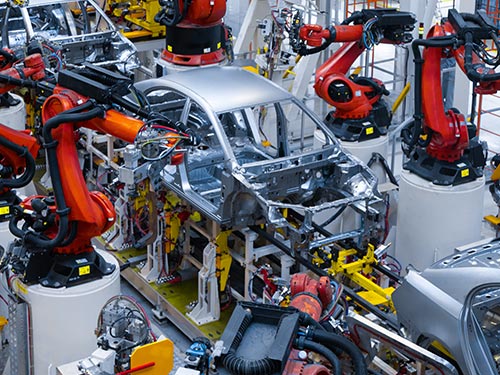

Tidak seperti tuangan dan kimpalan, penempaan bertujuan untuk mengoptimumkan struktur dan sifat fizikal bahan yang wujud. Perkhidmatan kami sesuai untuk industri yang mempunyai keperluan keselamatan dan ketahanan yang ketat, seperti automotif, aeroangkasa dan jentera berat. Kami menawarkan pelarasan pengeluaran yang fleksibel dan disesuaikan, daripada pengeluaran sekeping tunggal, kumpulan kecil kepada pengeluaran barisan pemasangan berskala besar, untuk memenuhi permintaan pasaran global yang pelbagai.

Tidak seperti tuangan dan kimpalan, penempaan bertujuan untuk mengoptimumkan struktur dan sifat fizikal bahan yang wujud. Perkhidmatan kami sesuai untuk industri yang mempunyai keperluan keselamatan dan ketahanan yang ketat, seperti automotif, aeroangkasa dan jentera berat. Kami menawarkan pelarasan pengeluaran yang fleksibel dan disesuaikan, daripada pengeluaran sekeping tunggal, kumpulan kecil kepada pengeluaran barisan pemasangan berskala besar, untuk memenuhi permintaan pasaran global yang pelbagai.

Keupayaan Penempaan Teras Kami

Kami pakar dalam meningkatkan sifat mekanikal bahagian dengan mengawal aliran bijirin logam dan menyediakan perkhidmatan pengeluaran besar-besaran yang boleh dipercayai:

| Kompetensi Teras | Penerangan dan Kelebihan |

| Sifat Mekanikal Cemerlang | Melalui proses ubah bentuk plastik, bahagian tersebut mempunyai struktur bijian yang dioptimumkan dan ketumpatan yang lebih tinggi, memastikan kekuatan, keliatan dan rintangan keletihan yang sangat baik. |

| Sistem Kualiti Standard Tinggi | Kami mematuhi sepenuhnya pensijilan ISO 9001:2015 dan IATF 16949:2016 untuk memenuhi sepenuhnya keperluan ketat industri automotif untuk prestasi komponen dan kawalan kualiti. |

| Pengeluaran Kelompok Fleksibel | Dengan model pengeluaran yang fleksibel, ia boleh disesuaikan mengikut permintaan dan menyokong keseluruhan proses daripada pengoptimuman reka bentuk kepada penghantaran berskala besar. |

| Pengalaman dan Pengoptimuman Reka Bentuk | Dengan lebih 18/20 tahun pengalaman dalam fabrikasi logam, beliau mampu mereka bentuk semula bahagian-bahagian agar sesuai dengan sempurna proses pengeluaran penempaan dan mengesyorkan proses pembuatan yang optimum. |

Pelbagai Aplikasi Dan Produk Teras

Tempaan merupakan komponen penting yang bertekanan tinggi dalam banyak sektor perindustrian dan pengangkutan yang kritikal. Kami terutamanya menawarkan perkhidmatan kepada industri yang memerlukan keselamatan, ketepatan dan ketahanan, dengan memanfaatkan teknologi Tempaan yang canggih.

Industri Auto:

Ia sesuai untuk mengeluarkan komponen utama dengan keperluan yang tinggi pada hayat lesu, seperti bahagian enjin, bahagian transmisi dan bahagian sistem brek.

Pembuatan Gandingan Industri:

Gandingan elastik/tegar, gandingan diafragma/gear boleh disesuaikan, dan penempaan memastikan kekuatan dan ketahanan bahagian transmisi ini.

Pembuatan Flange:

Pengeluaran bebibir kimpalan, bebibir kimpalan punggung, dsb. Struktur tempaan yang padat boleh memastikan pengedap dan keselamatannya dalam saluran paip tekanan tinggi.

Bahagian Mekanikal Am:

Penempaan sesuai untuk komponen mekanikal umum dan khusus, termasuk peralatan mesin dan robot perindustrian, yang memberikan kekuatan tinggi yang diperlukan untuk aplikasi yang mencabar.

Bagaimana Proses Pengeluaran Berfungsi

Kami ingin bekerja dengan kami dalam projek pengeluaran selancar dan selaras yang mungkin.

1

Bercakap dengan pakar pembuatan yang akan membantu anda menyesuaikan sebut harga pengeluaran anda di sekitar bil bahan yang lengkap.

2

Bekerjasama dengan pasukan kami untuk mengoptimumkan projek anda untuk pengeluaran, termasuk reka bentuk untuk pilihan kebolehkilangan dan pengurangan kos.

3

Sampel awal bahagian dibuat dan dihantar kepada anda untuk memastikan bahagian itu memenuhi piawaian anda sebelum pengeluaran penuh bermula.

4

Dapatkan ketelusan proses dan kawalan kualiti apabila pengeluaran penuh bermula.

5

Gunakan pasca pemprosesan dan langkah kualiti akhir sebelum bahagian dihantar.

6

Letakkan pesanan pengeluaran kelompok berikutnya untuk projek anda pada bila-bila masa melalui gudang maya kami.

Mulakan Projek Anda dengan Leierwo

1. Hantar Pertanyaan Anda

Hantar lukisan CAD dan fail 3D anda melalui e-mel, menyatakan gred bahan, kuantiti pesanan, kemasan permukaan atau sebarang butiran lain yang berkaitan.

2. Pengiraan Kos

Sebaik sahaja kami menerima reka bentuk anda, pasukan kejuruteraan kami akan menilai lukisan dengan teliti dan mengira harga berdasarkan kos pengeluaran sebenar secepat mungkin.

3. Mulakan Pengeluaran

Selepas kelulusan harga, pasukan pengeluaran kami akan menyediakan bahan dan menjadualkan pengeluaran dengan segera. Leierwo sentiasa memastikan penghantaran tepat pada masanya.

4. Susun Penghantaran

Selepas pengeluaran selesai, kami akan memberikan butiran pembungkusan dan mengatur penghantaran melalui laut atau udara. Kami menyokong penghantaran global untuk setiap pesanan.

Soalan Lazim

S1. Adakah anda sebuah syarikat perdagangan atau pengilang?

S2. Bolehkah anda memetik berdasarkan lukisan 3D?

S3. Bagaimanakah anda mengendalikan RFQ (Permintaan Sebutharga)?

S4. Apakah masa utama anda yang biasa?

S5. Adakah anda menyediakan sampel? Adakah mereka bebas?

S6. Apakah kaedah pembayaran yang anda terima?

S7. Bagaimanakah anda memastikan kawalan kualiti?

S8. Adakah produk anda disertakan dengan jaminan?

S9. Bagaimana anda melihat hubungan anda dengan pelanggan?