Pembuatan Coupler

Muat Turun Maklumat Produk

Untuk membantu pelanggan global memahami produk kami dengan lebih baik, kami komited untuk memberikan anda maklumat produk terperinci untuk membantu anda memilih produk yang memenuhi keperluan anda.

Kelebihan

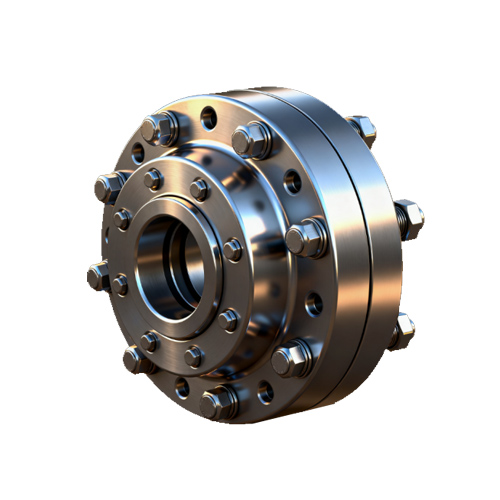

Couplers are essential components in mechanical transmission systems, connecting two shafts and transmitting torque. They are widely used in motors, pumps, fans, compressors, ships, mining machinery, and other equipment. They not only transmit power but also provide vibration damping, compensate for misalignment, and protect equipment operation.

As industrial equipment evolves toward higher power, higher precision, and greater automation, higher demands are placed on couplers for strength, precision, wear resistance, and fatigue resistance. Through the precise application of high-quality casting processes, Leerwo ensures that key coupler components possess excellent mechanical properties and structural stability, providing a strong guarantee for reliable equipment operation.

As industrial equipment evolves toward higher power, higher precision, and greater automation, higher demands are placed on couplers for strength, precision, wear resistance, and fatigue resistance. Through the precise application of high-quality casting processes, Leerwo ensures that key coupler components possess excellent mechanical properties and structural stability, providing a strong guarantee for reliable equipment operation.

Application of Casting in Coupler Manufacturing

Leierwo can customize various types of coupler castings, and our products are widely applicable to:

Rigid couplers, elastic couplers, hydraulic couplers, safety couplers, and other types.

Rigid couplers, elastic couplers, hydraulic couplers, safety couplers, and other types.

Key Advantages of Cast Coupler Components

Complete structure, formed in one piece, reduces welding and assembly errors.

Flexible material selection adapts to different operating requirements (ductile iron, alloy steel, stainless steel, etc.).

High strength and excellent wear resistance meet high speed and high torque conditions.

Excellent cost-effectiveness, suitable for mass production or custom production.

Through precision casting technology and strict heat treatment, we can provide customers with high-precision, high-strength coupler core components to ensure stable operation of the equipment under various working conditions.

Flexible material selection adapts to different operating requirements (ductile iron, alloy steel, stainless steel, etc.).

High strength and excellent wear resistance meet high speed and high torque conditions.

Excellent cost-effectiveness, suitable for mass production or custom production.

Through precision casting technology and strict heat treatment, we can provide customers with high-precision, high-strength coupler core components to ensure stable operation of the equipment under various working conditions.

Casting Materials and Process Characteristics

In the manufacture of coupler castings, we flexibly select materials and processes according to different product types and usage environments to ensure a balance between performance and life.

Common Casting Materials Include

Besi mulur

High toughness, good vibration damping, suitable for medium and large coupler housings.

Keluli Karbon

It has excellent load-bearing and processing properties and is suitable for general machinery and power equipment.

Keluli Aloi

High strength and fatigue resistance, meeting the requirements of high speed and high torque working conditions.

Keluli Tahan Karat

It has excellent corrosion resistance and is suitable for equipment in chemical, marine and high-humidity environments.

Aluminum Alloy

Lightweight and with good thermal conductivity, it is suitable for special fluid couplings.

Main Casting Process

Investment Casting: Suitable for core coupler components with complex structures and strict dimensional requirements. Produced in a single molding process, it achieves dimensional accuracy of CT6-CT8 and a high surface finish.

Sand Casting: Adapts to diverse operating conditions (ductile iron, alloy steel, stainless steel, etc.).

Die Casting: Meets high-speed and high-torque operating conditions.

3D Printing: Suitable for mass production or custom production.

Welding: Used for composite manufacturing of complex or high-load components, achieving structural reinforcement and weight optimization.

Sand Casting: Adapts to diverse operating conditions (ductile iron, alloy steel, stainless steel, etc.).

Die Casting: Meets high-speed and high-torque operating conditions.

3D Printing: Suitable for mass production or custom production.

Welding: Used for composite manufacturing of complex or high-load components, achieving structural reinforcement and weight optimization.

Industry Standards and Quality Control

We strictly adhere to domestic and international standards and customer requirements to ensure the stability and reliability of each coupler casting.

Implementation Standards:

GB/T, ISO, DIN, ASTM, and other relevant mechanical transmission standards.

Customization is available based on customer drawings and technical specifications.

Quality System and Testing Methods:

ISO 9001 quality management system certification.

Utilizes multiple inspection processes, including chemical composition analysis, dimensional testing, non-destructive testing, and dynamic balancing.

Implements full-process traceability, ensuring stringent quality control from raw material intake to product delivery.

We are committed to providing customers with high-performance, customized coupler castings, ensuring efficient, safe, and long-term stable operation of their equipment.

Implementation Standards:

GB/T, ISO, DIN, ASTM, and other relevant mechanical transmission standards.

Customization is available based on customer drawings and technical specifications.

Quality System and Testing Methods:

ISO 9001 quality management system certification.

Utilizes multiple inspection processes, including chemical composition analysis, dimensional testing, non-destructive testing, and dynamic balancing.

Implements full-process traceability, ensuring stringent quality control from raw material intake to product delivery.

We are committed to providing customers with high-performance, customized coupler castings, ensuring efficient, safe, and long-term stable operation of their equipment.

Apa yang Kami Tawarkan

Leierwo komited untuk menyediakan perkhidmatan pembuatan bahagian logam ketepatan berkualiti tinggi, termasuk tuangan ketepatan, tuangan pelaburan, tuangan pasir dan pemesinan CNC. Kami menawarkan penyelesaian tersuai dan boleh menyiapkan reka bentuk anda dalam masa 3–5 minggu, bergantung pada kerumitan bahagian tersebut. Sebelum pengeluaran besar-besaran, kami menyediakan satu sampel percuma untuk ujian dan kelulusan.

Perkhidmatan Pemutus Pelaburan

ciri-ciri: Tuangan pelaburan mempunyai ketepatan yang tinggi, boleh menyesuaikan diri dengan bentuk yang kompleks, mempunyai permukaan licin dan sedikit sisa bahan.

Aplikasi: aeroangkasa, jentera ketepatan, kereta, peralatan perubatan, dsb.

Perkhidmatan Tuang Pasir

ciri-ciri: Ia menggunakan acuan pasir, yang kos rendah dan sesuai untuk tuangan logam berbentuk besar dan kompleks.

Aplikasi: bahagian automotif, bahagian struktur mekanikal, tuangan besar.

Perkhidmatan Pemesinan CNC

ciri-ciri: ketepatan tinggi, bahagian kompleks, dan pengeluaran besar-besaran.

Aplikasi: acuan, bahagian peranti perubatan, blok silinder enjin aloi aluminium/kepala silinder.

Perkhidmatan Tuangan Kami – Dipenuhi Merentas Gred Logam

Leierwo memiliki kepakaran yang luas merentasi pelbagai gred aloi, membolehkan pelanggan kami memilih bahan yang ideal untuk mengoptimumkan produk mereka dan memenuhi keperluan aplikasi global yang paling mencabar. Sila terokai siri aloi yang disenaraikan di bawah untuk mencari padanan yang sesuai untuk keperluan khusus anda.

Kami Menyediakan Penyelesaian Pengilangan Komprehensif

Pemutus Pelaburan

Tuangan Pasir

Percetakan 3D

Tuangan Keluli Tahan Karat

Tuangan Keluli Karbon

Tuangan Keluli Aloi

Mulakan Projek Anda dengan Leierwo

1. Hantar Pertanyaan Anda

Hantar lukisan CAD dan fail 3D anda melalui e-mel, menyatakan gred bahan, kuantiti pesanan, kemasan permukaan atau sebarang butiran lain yang berkaitan.

2. Pengiraan Kos

Sebaik sahaja kami menerima reka bentuk anda, pasukan kejuruteraan kami akan menilai lukisan dengan teliti dan mengira harga berdasarkan kos pengeluaran sebenar secepat mungkin.

3. Mulakan Pengeluaran

Selepas kelulusan harga, pasukan pengeluaran kami akan menyediakan bahan dan menjadualkan pengeluaran dengan segera. Leierwo sentiasa memastikan penghantaran tepat pada masanya.

4. Susun Penghantaran

Selepas pengeluaran selesai, kami akan memberikan butiran pembungkusan dan mengatur penghantaran melalui laut atau udara. Kami menyokong penghantaran global untuk setiap pesanan.

Soalan Lazim

S1. Adakah anda sebuah syarikat perdagangan atau pengilang?

S2. Bolehkah anda memetik berdasarkan lukisan 3D?

S3. Bagaimanakah anda mengendalikan RFQ (Permintaan Sebutharga)?

S4. Apakah masa utama anda yang biasa?

S5. Adakah anda menyediakan sampel? Adakah mereka bebas?

S6. Apakah kaedah pembayaran yang anda terima?

S7. Bagaimanakah anda memastikan kawalan kualiti?

S8. Adakah produk anda disertakan dengan jaminan?

S9. Bagaimana anda melihat hubungan anda dengan pelanggan?