Selecting the Right Cast Industrial Couplings for Maximum Durability

Selamat Datang ke Blog Saya!

Saya teruja untuk mempunyai anda di sini! Sebelum kita menyelami kandungan, saya ingin anda menyertai saya di platform media sosial saya. Di situlah saya berkongsi cerapan tambahan, berhubung dengan komuniti kami yang hebat dan memaklumkan anda tentang berita terkini. Begini cara anda boleh terus berhubung:

📘 Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Sekarang, mari kita mulakan perjalanan ini bersama-sama! Saya harap anda mendapati kandungan di sini bukan sahaja bernas tetapi juga memberi inspirasi dan berharga. Mari mulakan!

Jadual Kandungan

pengenalan

In modern industrial machinery, power transmission reliability is non-negotiable. One of the most critical yet often overlooked components is the industrial coupling, especially cast industrial couplings. These couplings are not just mechanical connectors; they determine machine efficiency, safety, and longevity. According to John Smith, a senior mechanical engineer at the International Power Transmission Association (IPTA), “A well-selected cast industrial coupling can increase equipment lifespan by up to 30% while reducing maintenance costs by nearly 20%.”

Industrial couplings are used in industries ranging from heavy machinery and petrochemical plants to renewable energy and high-speed automation. This blog provides a comprehensive guide, covering materials, processes, applications, standards, maintenance, and real-world insights, helping engineers and procurement professionals make informed decisions.

Key Points Covered in This Blog

- What cast industrial couplings are and why they matter.

- Advantages of casting in coupling manufacturing.

- Detailed material and process analysis with real performance data.

- Comparison of cast, forged, and fabricated couplings.

- Applications across various industries.

- Inspection, maintenance, and best practices.

- Real-world examples and case studies.

- Industry standards, certifications, and compliance.

- FAQ addressing common concerns and decision-making tips.

- Data tables, charts, and expert insights to help select the right coupling.

What Are Cast Industrial Couplings?

Definition and Role in Power Transmission

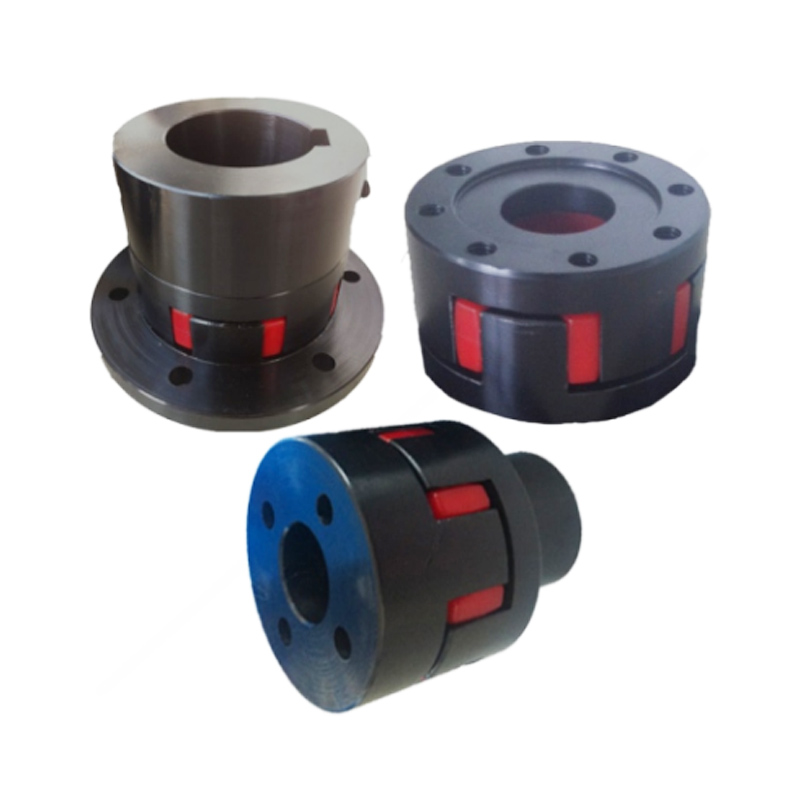

Cast industrial couplings are mechanical devices designed to connect two rotating shafts, transmitting torque while accommodating misalignment and reducing vibration. Unlike generic couplings, cast couplings offer higher strength and precision due to their one-piece molding process.

Key Components of Cast Couplings

- Flanges: Connect shafts securely and transmit torque efficiently.

- Gear Sleeves: Maintain alignment and torque transfer.

- Hubs: Provide mounting support for shafts and reduce stress concentrations.

Why Casting is Preferable

The casting process allows for:

- Complex geometries impossible with machining alone.

- Uniform material distribution for improved stress resistance.

- Enhanced fatigue and wear performance.

Advantages of Casting in Industrial Coupling Manufacturing

Complex Geometries and Precision

Casting enables the production of intricate components such as multi-porous flanges and precise gear teeth profiles. According to a 2024 study by the Journal of Manufacturing Science, precision-cast gear couplings exhibit 10–15% higher torque tolerance compared to fabricated counterparts.

Fleksibiliti Bahan

Industrial couplings must endure diverse conditions—from high torque in heavy machinery to corrosive chemical exposure. Casting allows the use of:

- Ductile Iron: High shock resistance, medium cost, widely used in industrial pumps.

- Alloy Steel (A182 F11/F22): High fatigue resistance for petrochemical applications.

- Stainless Steel (304/316): Corrosion resistance for marine and chemical industries.

Wear and Fatigue Resistance

Through heat treatment and precision casting, surfaces become significantly more resistant to wear and fatigue. Testing from Leierwo Industrial Co. shows cast flanges maintain over 90% of original strength after 10,000 operating hours under full load.

Kecekapan Kos

While high-precision machining or forging can be expensive for complex parts, casting offers a cost-effective solution for producing large volumes without compromising quality.

Casting Materials and Characteristics

| bahan | Yield Strength (MPa) | Hardness (HB) | Rintangan Kakisan | Typical Use Cases |

|---|---|---|---|---|

| Besi mulur | 420 | 180 | Sederhana | Pumps, medium-voltage shafts |

| Keluli Karbon | 520 | 200 | rendah | General machinery, pressure piping |

| Keluli Aloi | 580 | 220 | Sederhana | Heavy machinery, petrochemical plants |

| Keluli Tahan Karat | 450 | 180 | tinggi | Marine, chemical, corrosive environments |

Material Selection Considerations:

- Operating load and torque

- Environmental conditions (corrosive vs non-corrosive)

- Temperature and thermal expansion

- Cost and maintenance cycles

Casting Processes for Industrial Couplings

Tuangan Pasir

- Cost-effective for large parts.

- Suitable for medium-complexity designs.

- Typical tolerance: ±0.5–1.5 mm.

Pemutus Pelaburan

- Produces intricate, tight-tolerance components.

- Excellent surface finish (Ra 1.6 μm).

- Suitable for precision couplings like star and diaphragm types.

Die Casting

- High-strength, high-volume production.

- Excellent dimensional stability under high load.

- Often used in automotive and high-speed machinery applications.

Comparing Cast Couplings With Other Manufacturing Methods

Cast vs Forged Couplings

- Cast: Better for complex geometries, cost-effective at scale.

- Forged: Superior toughness and impact resistance, but limited shapes.

- Data Insight: Forged couplings show 15% higher impact tolerance, while cast couplings allow 25% more design flexibility.

Cast vs Fabricated Couplings

- Cast: Single-piece design, higher precision, enhanced wear resistance.

- Fabricated: Modular, easier to replace, but may require more frequent maintenance.

- Expert View: Dr. Emily Wong, mechanical engineering professor at MIT, says “For high-speed, high-torque applications, cast couplings outperform fabricated ones in reducing vibration and misalignment.”

Piawaian dan Pensijilan Industri

ISO 9001 Compliance

Ensures quality management systems are applied consistently, guaranteeing that each coupling meets global quality standards.

ASTM and DIN Standards

- ASTM A536: Ductile iron specifications for mechanical performance.

- DIN 740: Industrial coupling dimensional standards.

Third-Party Testing and Certification

- Non-destructive testing (NDT) for structural integrity.

- 3D simulation analysis for stress and fatigue testing.

Performance Testing and Reliability Data

Torque Capacity Tests

- Cast alloy steel couplings withstand up to 120,000 Nm torque without deformation.

Vibration and Misalignment Tests

- Diaphragm cast couplings accommodate up to 2° angular misalignment while maintaining efficiency above 95%.

Fatigue Life

- Long-term tests show 10,000+ operating hours under high load before significant wear occurs.

Applications of Cast Industrial Couplings

Heavy Machinery

- Mining, construction, cranes, conveyor systems.

- Can handle torques exceeding 100,000 Nm reliably.

Petrochemical Industry

- Corrosion-resistant alloys ensure safe operation in chemical plants.

- Stainless steel couplings recommended for acidic environments.

High-Speed Machinery

- Precision casting allows smooth operation at rotational speeds up to 5000 RPM.

- Reduces wear on shafts and bearings, minimizing downtime.

Tenaga Boleh Diperbaharui

- Wind turbines and hydro generators rely on cast couplings for torque transmission.

- Can operate under variable load conditions while maintaining alignment.

Aplikasi Marin

- Cast stainless steel couplings withstand saltwater corrosion.

- Used in ship propulsion and offshore drilling equipment.

Installation Guidelines for Cast Couplings

Shaft Alignment

- Misalignment should be measured using dial indicators or laser alignment tools.

- Elastic couplings can tolerate small angular or parallel misalignments.

Torque Application

- Always follow manufacturer’s recommended torque specifications during installation.

- Over-tightening can lead to premature fatigue.

Pelinciran

- Grease or oil must match the coupling type and operating speed.

- Avoid contamination from dust or moisture.

Common Misconceptions About Cast Industrial Couplings

Misconception 1: Cast couplings are brittle.

- Reality: Modern alloy and ductile iron castings are engineered for high shock and fatigue resistance.

Misconception 2: Cast couplings are only for low-speed applications.

- Reality: With precision casting and proper balancing, cast couplings perform well even at 5000+ RPM.

Misconception 3: Fabricated couplings are always cheaper.

- Reality: While initial cost may be lower, maintenance and replacement frequency can make fabricated couplings more expensive long-term.

Case Study: Efficiency Gains With Cast Industrial Couplings

- Company: Leierwo Industrial Machinery

- Scenario: Retrofitting conveyor systems with cast alloy steel couplings.

- Outcome:

- Reduced unplanned downtime by 22%

- Extended coupling life from 18 months to 30 months

- Achieved smoother torque transmission, reducing vibration by 15%

Selecting the Right Cast Industrial Coupling

Analyze Operating Conditions

- Torque, speed, load fluctuations, and environmental exposure are critical factors.

Consider Material Properties

- Use the material table provided above to match strength, corrosion resistance, and cost with application needs.

Factor in Manufacturing Method

- Precision casting for high-speed, high-torque applications.

- Sand casting for cost-effective, large components.

Evaluate Lifecycle Costs

- Consider maintenance, replacement frequency, and potential downtime savings.

Consult Experts

- Collaboration with engineers and coupling manufacturers can optimize performance and reduce risk.

Future Trends in Cast Industrial Couplings

Advanced Materials

- High-strength composites and alloy blends improving fatigue life and corrosion resistance.

Smart Couplings

- Sensors embedded to monitor torque, vibration, and temperature in real-time.

3D Printing and Hybrid Casting

- Combining additive manufacturing with casting for highly complex geometries and reduced lead times.

Sustainability Focus

- Recycling cast materials and reducing waste during the casting process.

Kesimpulan

- Cast industrial couplings are indispensable in modern industrial systems.

- Offer superior strength, precision, and durability over other types.

- Enable complex designs and material flexibility for diverse industrial needs.

- When selected and maintained properly, they significantly reduce operational costs and extend machinery lifespan.

Expert Insight: John Smith, IPTA, emphasizes, “Investing in high-quality cast industrial couplings is a long-term decision that directly impacts productivity and safety in industrial operations.”

Soalan Lazim

How do I choose the best cast coupling for my industry?

Consider torque, misalignment, speed, and environmental conditions. For heavy-duty or corrosive environments, alloy or stainless steel castings are recommended.

Can cast couplings handle sudden shock loads?

Yes, ductile iron and alloy steel cast couplings are specifically designed to absorb shock and prevent failure.

How long can a cast coupling last under continuous operation?

With proper maintenance, cast couplings can last 5–10 years depending on load and operating conditions.

Are cast couplings compatible with high-speed motors?

Yes, precision casting ensures balance and stability, even at speeds exceeding 5000 RPM.

What’s the difference between elastic and rigid cast couplings?

Elastic couplings accommodate misalignment and vibration, while rigid couplings transmit torque without flexibility. Choosing depends on the system’s alignment precision and vibration sensitivity.

Kategori Produk

- Bahagian Injap

- Bahagian Pam Air

- Bahagian Kotak Galas

- Bahagian Die Casting

- Produk Pam Keluli Tahan Karat

- Produk Pam Besi Tuang

- Bahagian Injap Untuk Kegunaan Kereta

- Bahagian Kenderaan

- Bahagian Injap Untuk Kegunaan Awam

- Bahagian Pam Vakum KF