Elakkan 3 Aksesori Pam Air Ini Yang Membuang Wang!

Selamat Datang ke Blog Saya!

Saya teruja untuk mempunyai anda di sini! Sebelum kita menyelami kandungan, saya ingin anda menyertai saya di platform media sosial saya. Di situlah saya berkongsi cerapan tambahan, berhubung dengan komuniti kami yang hebat dan memaklumkan anda tentang berita terkini. Begini cara anda boleh terus berhubung:

📘 Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Sekarang, mari kita mulakan perjalanan ini bersama-sama! Saya harap anda mendapati kandungan di sini bukan sahaja bernas tetapi juga memberi inspirasi dan berharga. Mari mulakan!

Jadual Kandungan

pengenalan

When maintaining or upgrading water pump systems, selecting the right water pump accessories is critical for both efficiency and cost-effectiveness. However, not all accessories deliver their promised benefits – some can lead to unnecessary expenses and reduced performance.

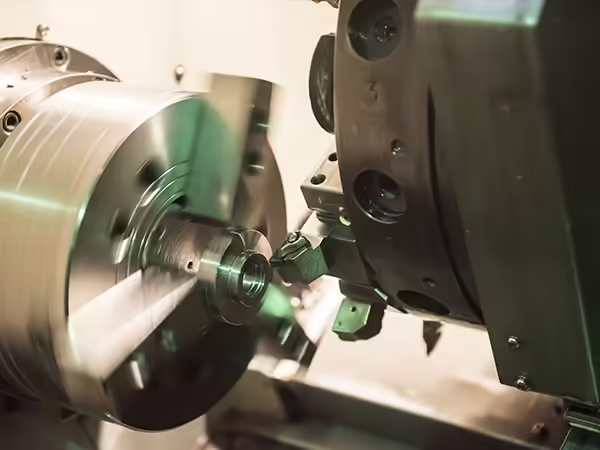

Shanghai Leierwo Industry & Trade Co., Ltd. specializes in high-quality metal casting and CNC machining, producing durable water pump parts including chemical pump bodies, centrifugal pump impellers, and casings. With over 18 years of experience in precision casting, we understand the importance of reliable components that enhance pump performance rather than waste money.

This article will examine three common water pump accessories that may appear useful but often result in wasted investment. We’ll also provide guidance on identifying high-quality alternatives.

NO 1. Low-Quality Gaskets and Seals: A Common Money Trap

Why They Waste Money

Budget-friendly gaskets and seals are frequently manufactured from inferior materials that deteriorate rapidly under pressure, temperature fluctuations, and chemical exposure. While initially appearing cost-effective, these low-grade components often require frequent replacement due to premature wear, cracking, or compression set failure. Even minor leaks can lead to significant long-term expenses, including:

- Fluid loss and contamination – Increasing operational costs and environmental risks

- System downtime – Reducing productivity and requiring additional labor for repairs

- Secondary damage – Corrosion or wear on adjacent components due to leaks

Superior Alternatives for Long-Term Savings

To avoid these pitfalls, investing in high-performance sealing solutions is essential. Key factors to consider include:

- Material durability – Nitrile rubber (NBR) excels in oil and fuel resistance, while fluorocarbon (FKM) provides superior heat and chemical resistance for demanding environments.

- Precision fit – Ensure components match OEM specifications to prevent leaks and maintain system integrity.

- Certified suppliers – Manufacturers adhering to ISO 9001 and IATF 16949 standards guarantee consistent quality and reliability.

By selecting premium gaskets and seals, businesses can minimize downtime, reduce maintenance costs, and extend equipment lifespan.

NO 2. Cheap Plastic Impellers: A Hidden Performance Killer

The Problems with Plastic

Plastic impellers are often marketed as lightweight, affordable alternatives to metal versions. However, they exhibit several critical disadvantages that compromise pump performance and efficiency:

- Reduced hydraulic efficiency – Poor fluid dynamics increase energy consumption, raising operational costs.

- Premature failure – Susceptibility to cracking, warping, and erosion under high-speed operation leads to frequent replacements.

- Cavitation damage – Plastic is prone to pitting and erosion when vapor bubbles collapse, accelerating wear.

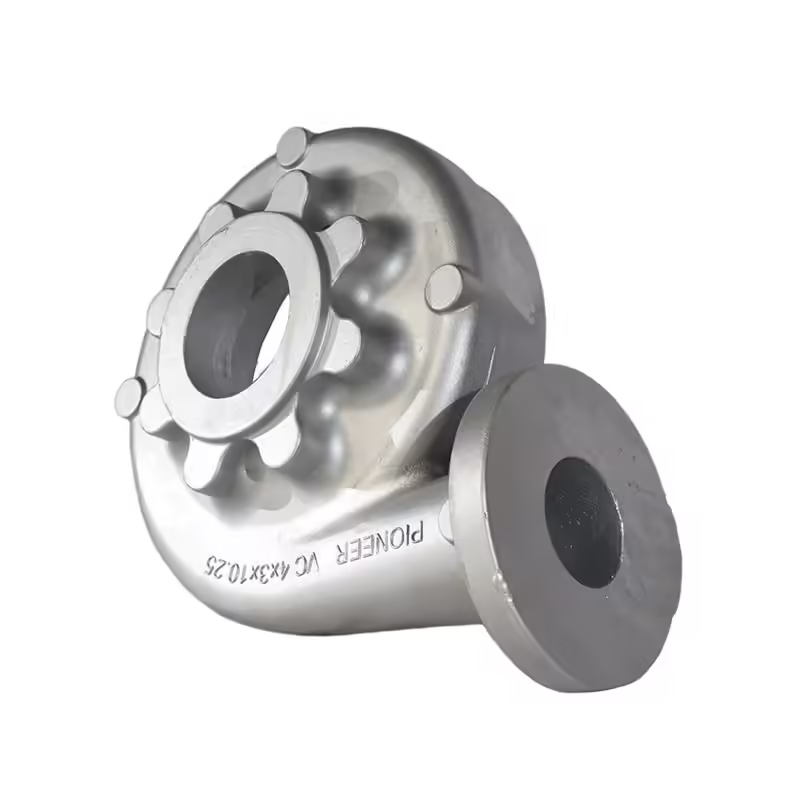

Leierwo‘s Superior Solutions

To overcome these limitations, our investment-cast stainless steel and alloy steel impellers provide unmatched durability and efficiency:

- Extended lifespan – Resistant to wear, corrosion, and cavitation, reducing replacement frequency.

- Optimized blade design – Engineered for maximum fluid dynamics, improving pump efficiency and lowering energy costs.

- Customizable options – Tailored designs for specific pump models to ensure perfect compatibility.

| bahan | Ketahanan | Aplikasi Terbaik | Kecekapan Kos |

|---|---|---|---|

| Plastic | rendah | Low-pressure applications | Short-term savings |

| Keluli Tahan Karat | tinggi | Chemical & industrial pumps | Long-term investment |

| Keluli Aloi | Sangat Tinggi | High-speed centrifugal pumps | Best ROI |

For industries requiring reliability and efficiency, metal impellers deliver superior performance and long-term savings.

NO 3. Oversized or Mismatched Couplings: An Efficiency Drain

Performance Issues

Couplings that are incorrectly sized or mismatched to the pump system can lead to multiple operational problems, including:

- Excessive vibration – Accelerates bearing and shaft wear, increasing maintenance costs.

- Misalignment stress – Causes uneven load distribution, leading to premature component failure.

- Energy inefficiency – Poor torque transfer results in higher power consumption and wasted energy.

Leierwo‘s Precision Solutions

Our CNC-machined couplings are engineered to maximize efficiency and reliability:

- Vibration minimization – Precision-balanced operation reduces stress on connected components.

- Optimal torque transfer – Ensures smooth power transmission, lowering energy waste.

- Custom sizing – Perfect fit for specific pump models to prevent misalignment and improve longevity.

By investing in properly sized, high-quality couplings, businesses can enhance system efficiency, reduce downtime, and achieve significant long-term cost savings.

Kesimpulan

Avoiding low-quality water pump accessories prevents frequent breakdowns and inefficiencies, ultimately saving money. Durable, precision-engineered parts from reputable manufacturers like Leierwo offer superior performance and cost-effectiveness.With our extensive experience in metal casting and CNC machining, we provide customized pump components that enhance performance while reducing lifecycle costs. Our investment casting and sand casting services ensure reliable solutions for all your water pump accessory needs.

Soalan Lazim

How can I identify high-quality water pump accessories?

When selecting premium Water Pump Accessories, always check for international material certifications like ASTM, DIN, and ISO standards, which validate the components’ durability and performance. Reputable suppliers like Leierwo further ensure quality through rigorous testing protocols – our IATF 16949 certification demonstrates automotive-grade quality control specifically for Water Pump Accessories. Additional indicators include precision machining tolerances, corrosion-resistant materials, and documented performance testing results for pump-specific applications.

Adakah Leierwo offer custom-designed water pump parts?

Yes, our engineering team specializes in developing custom Water Pump Accessories tailored to unique system requirements. We offer comprehensive design-to-production services including CAD modeling, material selection advice, and performance optimization for pump components. Whether you need modified impellers, custom volute casings, or specialized mounting brackets for your Water Pump Accessories, our foundry and CNC machining capabilities can accommodate both prototype and mass production needs while maintaining strict quality standards.

What’s the typical lead time for custom pump parts?

The lead time for bespoke Water Pump Accessories typically ranges between 3-5 weeks from design approval to shipment, depending on the complexity of components and order quantity. For critical Water Pump Accessories projects, we recommend requesting free sample parts for performance testing before full production. This allows for real-world validation of dimensions, material properties, and hydraulic efficiency in your specific pump configuration, ensuring optimal results in the final manufactured components.

Are stainless steel impellers worth the additional cost?

For demanding pump applications, stainless steel Water Pump Accessories like impellers deliver superior long-term value despite higher initial costs. The material’s exceptional corrosion resistance prevents pitting and erosion in harsh fluids, while its mechanical strength maintains precise blade geometry under continuous operation. When calculating total cost of ownership for Water Pump Accessories, stainless steel components often prove more economical due to extended service life, reduced downtime, and consistent efficiency in marine, chemical, and high-temperature pumping environments.

Which industries use Leierwo‘s water pump components?

Our precision-engineered Water Pump Accessories serve diverse industries including chemical processing plants (for acid and solvent transfer), agricultural irrigation systems, marine and offshore pumping solutions, and industrial cooling/heating circuits. The versatility of our Water Pump Accessories makes them suitable for anything from municipal water treatment to food-grade fluid handling, with material options ranging from bronze and ductile iron to super alloys for extreme conditions. Each sector benefits from our components’ reliable performance, energy-efficient designs, and compliance with industry-specific safety standards.

Kategori Produk

- Bahagian Injap

- Bahagian Pam Air

- Bahagian Kotak Galas

- Bahagian Die Casting

- Produk Pam Keluli Tahan Karat

- Produk Pam Besi Tuang

- Bahagian Injap Untuk Kegunaan Kereta

- Bahagian Kenderaan

- Bahagian Injap Untuk Kegunaan Awam

- Bahagian Pam Vakum KF