Panduan Terbaik untuk Tuangan Aloi Nikel dan Tuangan Nikel

Jadual Kandungan

pengenalan

Nickel casting dan nickel alloy castings are essential for high-performance metal components. These castings offer strength, corrosion resistance, and high-temperature stability, making them ideal for aerospace, chemical, energy, and medical industries.

Contoh: Turbine blades made from nickel alloy castings maintain their shape and performance even under extreme heat and operational stress.

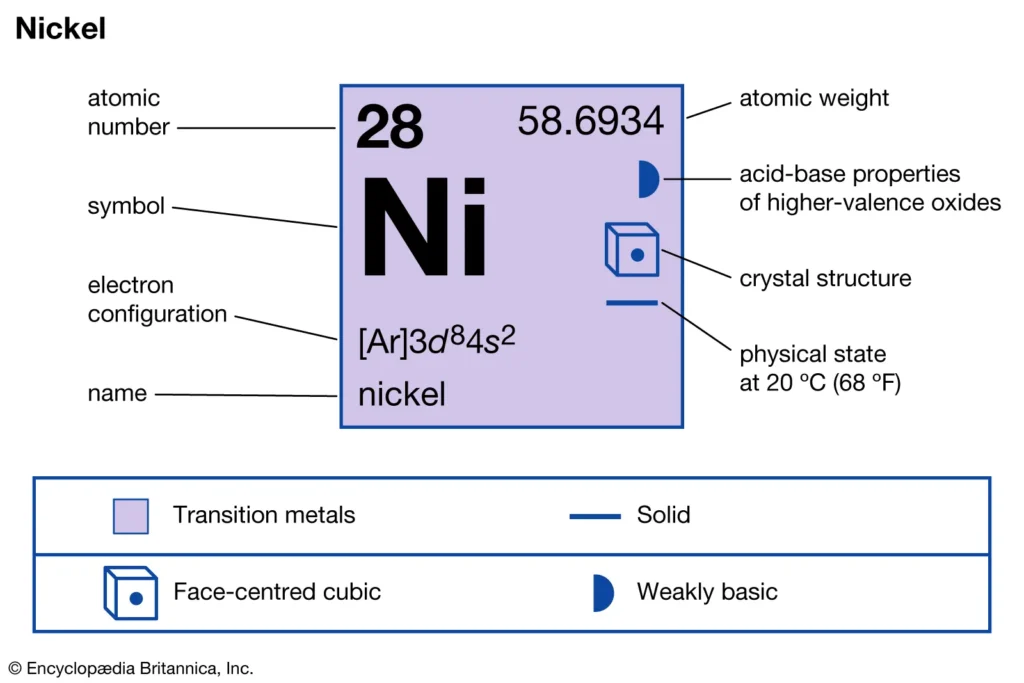

Apa itu Nickel? Properties and Benefits for Castings

Nickel as a Metal

Nickel is a silvery-white transition metal with a high melting point (~1455°C), ductility, dan natural corrosion resistance.

How Nickel Improves Castings

When added to alloys, nickel enhances strength, toughness, and wear resistance, while also providing oxidation resistance.

Contoh: Nickel in turbine casings prevents oxidation during prolonged exposure to hot gases, extending component lifespan.

Kefahaman Tuangan Aloi Nikel

Definition and Overview

Nickel alloy castings are components created by casting molten nickel-based alloys into molds. Combining nickel with metals like chromium, molybdenum, or cobalt enhances performance for specific applications.

Pure Nickel vs. Nickel-Based Alloys

Pure nickel castings are favored for chemical and marine applications due to corrosion resistance. Nickel-based alloys, however, offer higher strength and durability for high-stress or high-temperature uses.

Contoh: Monel alloy castings are widely used in pumps and valves handling acidic solutions, while Inconel castings are chosen for jet engine turbines.

Benefits of Nickel Castings

Rintangan Kakisan

Nickel alloy castings resist oxidation, rust, and chemical attack, making them reliable in harsh environments.

Contoh: Hastelloy cast pumps can operate for over 10 years in chemical plants without significant degradation.

Prestasi Suhu Tinggi

These castings maintain mechanical strength and dimensional stability even above 1000°C, crucial for engines and turbines.

Contoh: Gas turbine blades using Inconel castings endure continuous high-temperature operation without warping.

Strength and Wear Resistance

Nickel enhances tensile strength, toughness, and hardness, extending component life in demanding mechanical applications.

Contoh: Nimonic castings in jet engines resist creep and fatigue, ensuring reliability after thousands of flight hours.

Types of Nickel Alloys and Applications

Inconel for Extreme Heat

Inconel castings provide high-temperature strength and oxidation resistance, ideal for aerospace turbine blades.

Monel for Corrosive Environments

Monel castings excel in marine and chemical applications, offering resistance to acids, salts, and alkalis.

Hastelloy for Chemical Stability

Hastelloy castings maintain mechanical integrity under stress and provide superior chemical resistance, suitable for reactors and process equipment.

Nimonic for High-Temperature Components

Nimonic castings offer creep resistance and dimensional stability, used in jet engines and gas turbines.

Comparison Table: Nickel Alloys Performance

| Aloi | Rintangan Kakisan | High-Temperature Strength | Kekuatan Tegangan (MPa) | Typical Application |

|---|---|---|---|---|

| Inconel | tinggi | Sangat Tinggi | 1100 | Turbine blades, aerospace engines |

| Monel | Sangat Tinggi | Sederhana | 580 | Marine equipment, chemical pumps |

| Hastelloy | Extremely High | tinggi | 750 | Reactors, nuclear equipment |

| Nimonic | Sederhana | Extremely High | 950 | Jet engines, gas turbines |

This table provides quantitative data to help engineers select the most suitable nickel alloy casting based on strength, corrosion resistance, and operating temperature.

Manufacturing Nickel Castings

Sand Casting for Large Components

Sand casting uses sand molds to shape molten nickel alloys, suitable for pump housings or structural parts.

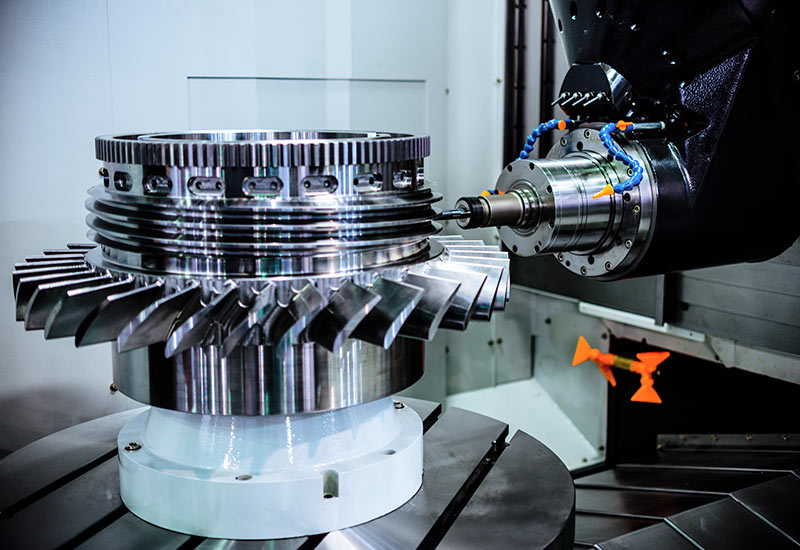

Investment Casting for Precision Parts

Investment casting, or lost wax casting, creates intricate geometries with high accuracy. Ideal for turbine blades or aerospace components.

Centrifugal Casting for Cylindrical Parts

Centrifugal casting uses rotation to produce dense, defect-free tubular or cylindrical components, seperti pipes and rings.

Contoh: Complex nickel alloy valves in chemical plants are cast using investment casting to ensure smooth internal channels and corrosion resistance.

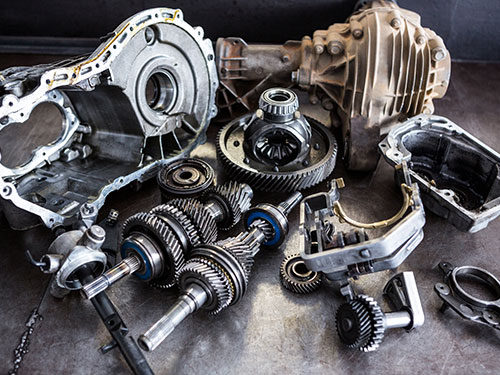

Aplikasi daripada Tuangan Aloi Nikel

Aerospace and Aviation

Nickel alloy castings are used in turbine blades, combustion chambers, and exhaust components, where high-temperature strength and creep resistance are essential.

Chemical and Marine Industry

Pumps, valves, and reactor vessels rely on nickel alloy castings for corrosion resistance to acids and saline solutions.

Energy Sector

Gas turbines and nuclear reactor components benefit from dimensional stability and long-term reliability provided by nickel castings.

Peralatan Perubatan

Surgical instruments and implants made from nickel alloy castings maintain sharpness and corrosion resistance after repeated sterilization cycles.

Maintenance and Longevity

Cleaning and Protective Measures

Routine cleaning removes deposits, while protective coatings reduce oxidation and wear, extending service life.

High-Temperature Considerations

Avoid thermal shock to prevent micro-cracks that can compromise structural integrity.

Periodic Inspection

Regular inspection ensures wear, stress corrosion, or surface defects are detected early, maintaining long-term reliability.

Soalan Lazim

Apakah perbezaan antara nickel casting dan nickel alloy casting?

Nickel casting is primarily pure nickel, while nickel alloy casting contains additional metals to enhance strength, wear resistance, or corrosion resistance.

Why are nickel castings more corrosion-resistant than steel?

Nickel forms a stable protective oxide layer, preventing rust and chemical degradation, even in acidic or saline environments.

Which nickel alloy is best for high-temperature applications?

Inconel and Nimonic provide superior strength and creep resistance at temperatures above 1000°C.

boleh nickel castings be used in chemical plants?

Yes. Alloys such as Monel and Hastelloy resist acids, bases, and harsh chemicals, ensuring long service life.

How do I select the right nickel alloy casting for my project?

Pertimbangkan temperature range, corrosion exposure, mechanical load, geometry, and cost. Comparison tables help identify the optimal alloy.

Kesimpulan

Nickel alloy castings dan nickel casting offer exceptional corrosion resistance, high-temperature performance, strength, and wear resistance. They are crucial for aerospace, chemical, energy, and medical industries.

By understanding nickel properties, alloy types, casting methods, and applications, engineers can choose the right material, optimize workflow, and extend component lifespan. Proper maintenance ensures reliable performance in demanding environments.

Kekal Berhubung dengan Kami

Terima kasih kerana membaca! Kami berharap blog ini memberi anda pandangan dan inspirasi yang berharga mengenai siling panel akustik. Jika anda menikmati kandungan tersebut dan ingin sentiasa dikemas kini dengan aliran terkini, petua dan kemas kini di sebalik tabir, kami ingin berhubung dengan anda di media sosial.

📘 Ikuti kami di Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Sertai komuniti kami yang semakin berkembang di mana kami berkongsi nasihat pakar, sorotan produk dan perbincangan interaktif dengan profesional dan peminat reka bentuk dari seluruh dunia.

Mari teruskan perbualan—jumpa anda di sana!

Kategori Produk

- Bahagian Injap

- Bahagian Pam Air

- Bahagian Kotak Galas

- Bahagian Die Casting

- Produk Pam Keluli Tahan Karat

- Produk Pam Besi Tuang

- Bahagian Injap Untuk Kegunaan Kereta

- Bahagian Kenderaan

- Bahagian Injap Untuk Kegunaan Awam

- Bahagian Pam Vakum KF