6 Kecacatan Tuang Nat Injap Kritikal untuk Dielakkan

Selamat Datang ke Blog Saya!

Saya teruja untuk mempunyai anda di sini! Sebelum kita menyelami kandungan, saya ingin anda menyertai saya di platform media sosial saya. Di situlah saya berkongsi cerapan tambahan, berhubung dengan komuniti kami yang hebat dan memaklumkan anda tentang berita terkini. Begini cara anda boleh terus berhubung:

📘 Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Sekarang, mari kita mulakan perjalanan ini bersama-sama! Saya harap anda mendapati kandungan di sini bukan sahaja bernas tetapi juga memberi inspirasi dan berharga. Mari mulakan!

Jadual Kandungan

pengenalan

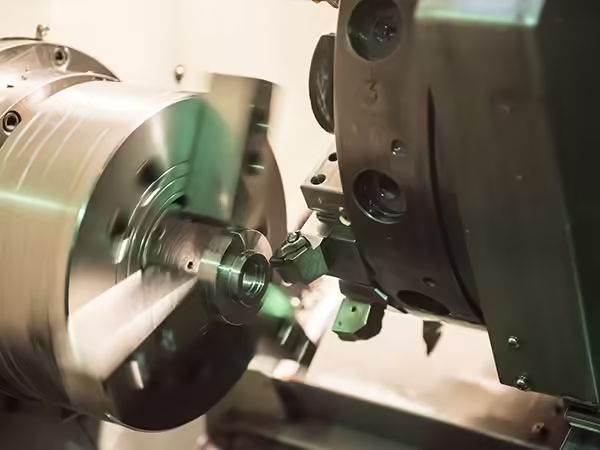

In many industrial applications, tuangan nat injap are foundational components that significantly influence operational performance and longevity. These castings, typically made from high-strength materials, are used in a variety of sectors including oil and gas, water systems, power generation, and manufacturing. Despite their critical role, overlooked flaws in valve nut castings can lead to unexpected system failures, operational inefficiencies, and increased maintenance costs. This guide explores six major flaws in valve nut castings and how you can prevent them to maintain safety, reliability, and cost-efficiency in your systems.

Porosity in Valve Nut Castings

Porosity remains one of the most prevalent and challenging defects encountered in valve nut castings. It refers to the presence of tiny voids or air pockets within the metal structure, which form during the solidification phase of the casting process. These microscopic cavities significantly reduce the casting’s density, leading to compromised mechanical properties such as reduced tensile strength and fatigue resistance.

Causes of Porosity

- Inadequate Degassing of Molten Metal: When molten metal contains dissolved gases like hydrogen or nitrogen, these gases tend to come out of solution as the metal cools, forming bubbles trapped inside the casting.

- Poor Mold Design or Venting: Insufficient venting or poorly designed molds can trap gases, preventing their escape and causing bubbles to become enclosed within the casting.

- Use of Low-Quality Raw Materials: Impurities or contaminants in raw materials can increase gas entrapment or chemical reactions that produce gases during solidification.

- Excessive Moisture in the Mold: Moisture can vaporize during pouring, generating steam that gets trapped as porosity.

Impact of Porosity

The existence of porosity can create weak points that act as stress concentrators. Over time, under cyclic loads or harsh service conditions, these stress concentrators may develop into cracks, potentially leading to catastrophic failure of the valve nut. This failure can disrupt the entire valve operation, causing costly downtime and repairs. Furthermore, porosity can affect sealing surfaces, reduce corrosion resistance, and complicate subsequent machining operations.

Prevention Tips

- Employ Vacuum Casting Techniques: Vacuum casting reduces the atmospheric pressure around the molten metal, helping to remove dissolved gases before solidification.

- Use High-Purity Materials: Starting with clean, high-quality metals decreases the likelihood of gas formation and entrapment.

- Ensure Optimal Mold Ventilation: Proper venting channels and degassing systems in mold design facilitate the escape of trapped gases, minimizing porosity formation.

- Control Pouring Temperature and Rate: A consistent pouring process can reduce turbulence and prevent gas entrapment.

- Preheat Molds to Eliminate Moisture: Eliminating water from the mold prevents steam-induced porosity.

Shrinkage Defects in Valve Nut Castings

Shrinkage defects occur when there is a volumetric contraction of metal during cooling. If not properly managed, it leads to voids or internal cracks within the valve nut castings. These defects significantly reduce the component’s load-bearing capabilities and can go undetected until failure occurs under stress conditions. Shrinkage defects are typically categorized into two types: macro-shrinkage, which is visible and localized, and micro-shrinkage, which consists of small voids spread throughout the material.

Factors Influencing Shrinkage:

- Poor riser placement in molds

- Incorrect pouring temperature

- Inconsistent cooling rates

- Insufficient alloy feeding systems

- Improper design leading to isolated hot spots

Solutions:

- Use computer simulations for mold design to identify and resolve potential shrinkage zones

- Add feeders to compensate for shrinkage during solidification

- Monitor and control pouring temperature precisely to ensure uniform cooling

- Design for directional solidification to avoid isolated hot spots and ensure a controlled solidification path

- Employ chills to accelerate solidification in specific areas and balance cooling rates

Misruns and Cold Shuts in Valve Nut Castings

A misrun occurs when the molten metal fails to completely fill the mold cavity, while a cold shut is a line or crack formed when two streams of metal do not fuse properly. Both flaws compromise the structural integrity and appearance of the valve nut castings. In some cases, these defects may not be visible externally, requiring advanced inspection techniques. If not detected and addressed, misruns and cold shuts can result in premature failure during operation.

Common Causes:

- Low pouring temperatures that reduce metal fluidity

- Inadequate gating system that restricts smooth metal flow

- Excessive turbulence during pouring that cools the metal prematurely

- High oxidation tendency of the alloy, leading to film barriers between streams

- Molds that are too cold, preventing proper metal flow

Prevention:

- Optimize gating system design to ensure smooth and continuous flow of molten metal

- Maintain recommended pouring temperature to keep the metal fluid

- Use fluidity-enhancing alloy additions to improve metal flow

- Ensure clean and dry molds to improve flow and fusion of metal streams

- Preheat molds to avoid premature solidification at the contact surface

Table: Common Valve Nut Castings Flaws and Their Impacts

| Flaw Type | Penerangan | Primary Causes | Impact on Performance |

|---|---|---|---|

| Keliangan | Tiny air pockets or voids in casting | Gas entrapment, poor mold venting | Reduces strength and durability |

| Shrinkage | Internal voids due to volume contraction | Inadequate risers, fast cooling | Decreases load-bearing capacity |

| Misruns | Incomplete filling of mold | Low temperature, poor gating | Structural weakness |

| Cold Shuts | Incomplete fusion of metal streams | Poor metal flow, cold mold surfaces | Causes cracks and weak joints |

| Inclusions | Foreign particles trapped within the casting | Contaminated metal, dirty molds | Degrades mechanical properties |

| Ketidaktepatan Dimensi | Deviations from specified dimensions | Mold wear, thermal expansion | Affects assembly and functionality |

Inclusion Defects in Valve Nut Castings

Inclusions refer to foreign materials—such as slag, sand, or oxides—trapped inside valve nut castings. These inclusions act as stress risers and significantly weaken the mechanical properties of the component. Often invisible on the surface, inclusions can lead to unpredictable behavior during operation, especially under high pressure or repeated loading.

Root Causes:

- Dirty molds contaminated with sand or previous residues

- Contaminated molten metal due to poor storage or handling of raw materials

- Inadequate skimming that fails to remove surface slag before pouring

- Excessive turbulence during pouring that allows oxides and debris to mix into the metal

How to Avoid:

- Use high-quality and clean molds free of loose particles

- Filter molten metal during pouring using ceramic foam filters

- Regularly clean and maintain melting furnaces to avoid contamination build-up

- Apply inert gas shielding for reactive alloys to reduce oxidation

- Minimize turbulence by optimizing gating system and pouring techniques

Dimensional Inaccuracies in Valve Nut Castings

Even a slight deviation in dimensions can lead to functional issues in valve nut castings. Dimensional inaccuracies not only prevent proper fitment but also lead to increased stress, accelerated wear, or even system failure. Precision is essential in high-pressure applications where tight tolerances are mandatory.

Key Contributors:

- Mold degradation due to repeated thermal cycling and mechanical wear

- Miscalculations in thermal expansion during casting design phase

- Poor pattern design that doesn’t account for shrinkage or distortion

- Inconsistent cooling or solidification, leading to warping or deformation

Best Practices:

- Use precise pattern-making techniques and robust materials

- Regularly calibrate measuring tools and inspection gauges

- Account for material behavior and thermal expansion in CAD modeling

- Employ 3D scanning and coordinate measuring machines (CMMs) for dimensional validation

- Replace or refurbish worn molds to maintain accuracy over long production runs

Kesimpulan

Understanding and avoiding these six critical flaws can save manufacturers and system operators significant costs and downtime. Each flaw—whether it be porosity, shrinkage, misruns, cold shuts, inclusions, or dimensional inaccuracies—has a specific root cause and preventive measure. Investing in quality control, advanced casting techniques, and thorough inspections ensures that your valve nut castings perform reliably under demanding conditions. In an industry where precision and reliability are non-negotiable, eliminating casting flaws is not just recommended—it’s essential.

Soalan Lazim

What materials are commonly used for tuangan nat injap?

Common materials include ductile iron, carbon steel, stainless steel, and bronze, selected based on the intended application.

How can I detect casting flaws early?

Techniques such as ultrasonic testing, X-ray inspection, and dye penetrant testing are effective in identifying internal and surface defects.

What standards should valve nut castings comply with?

Depending on the industry, castings should comply with standards like ASTM A216, A351, or ISO 8062.

Are machined valve nut castings better than as-cast ones?

Yes, machining can enhance dimensional accuracy and surface finish, reducing the likelihood of operational issues.

How often should valve nut castings be inspected?

Regular inspections should align with operational intensity—critical applications may require monthly checks, while others can be quarterly.

Kategori Produk

- Bahagian Injap

- Bahagian Pam Air

- Bahagian Kotak Galas

- Bahagian Die Casting

- Produk Pam Keluli Tahan Karat

- Produk Pam Besi Tuang

- Bahagian Injap Untuk Kegunaan Kereta

- Bahagian Kenderaan

- Bahagian Injap Untuk Kegunaan Awam

- Bahagian Pam Vakum KF