Industrial Coupling Manufacturing

Product Information Download

In order to help global customers better understand our products, we are committed to providing you with detailed product information to help you choose the products that meet your needs.

Advantages

Leierwo has significant advantages in industrial coupling casting, strictly adhering to the ISO 9001 quality management system and international standards such as ASTM and DIN. This ensures every coupling achieves high precision, reliability, and performance.

We offer a wide range of high-performance alloy materials tailored to customer requirements, ensuring couplings exhibit excellent corrosion resistance, wear resistance, and mechanical strength, meeting the stringent demands of industries such as petrochemical, machinery manufacturing, and heavy equipment.

Advanced casting techniques, including investment casting, precision sand casting, and die casting, ensure that industrial couplings maintain stability under high loads, high speeds, and extreme operating conditions. Couplings are further verified through 3D simulation analysis and non-destructive testing, guaranteeing consistent quality and performance.

We offer a wide range of high-performance alloy materials tailored to customer requirements, ensuring couplings exhibit excellent corrosion resistance, wear resistance, and mechanical strength, meeting the stringent demands of industries such as petrochemical, machinery manufacturing, and heavy equipment.

Advanced casting techniques, including investment casting, precision sand casting, and die casting, ensure that industrial couplings maintain stability under high loads, high speeds, and extreme operating conditions. Couplings are further verified through 3D simulation analysis and non-destructive testing, guaranteeing consistent quality and performance.

Application of Casting in Coupling Manufacturing

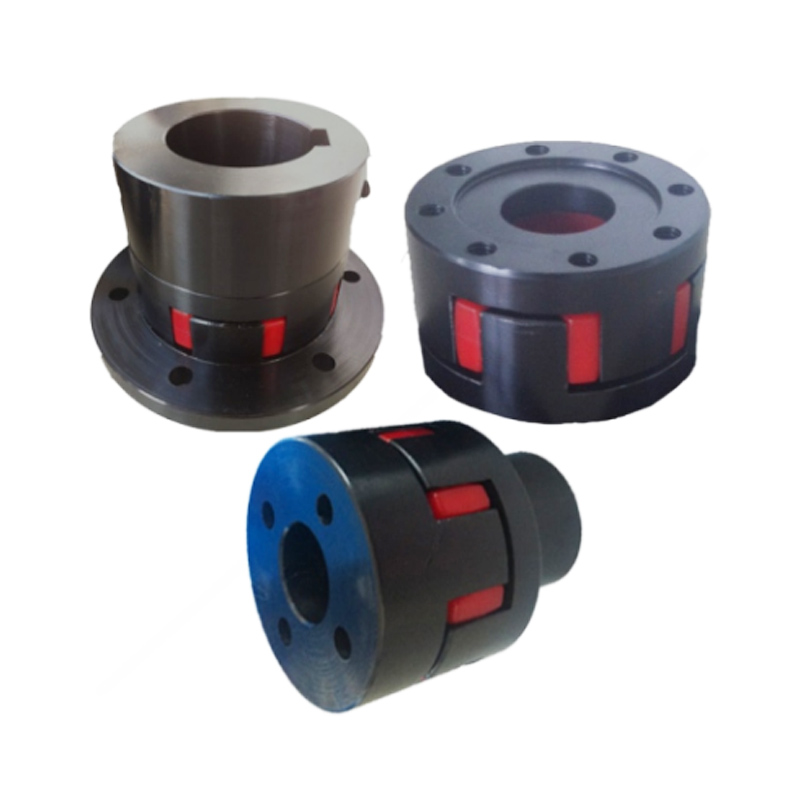

TS-B Star Elastic Coupling

TS-B Star Elastic Coupling

TS-B Star Elastic Coupling

TS-B Star Elastic Coupling

Lms Type Plum Blossom Coupling

Diaphragm Coupling

Lmp Type Plum Blossom Elastic Coupling With Brake Disc

Lmp Type Plum Blossom Elastic Coupling With Brake Disc

Industrial couplings are core components in power transmission systems. Key parts typically include gear couplings, sleeves, flanges, and more. Through the casting process, these components can achieve a single-piece molding process for complex structures while ensuring high strength and reliability.

The Advantages of Casting in Industrial Coupling Manufacturing are Mainly Reflected in

Complex shapes can be formed in one go: Meeting complex design requirements such as gear tooth profiles and multi-porous flange structures.

Flexible material selection: A variety of high-performance materials, including ductile iron, alloy steel, carbon steel, and stainless steel, can be used to meet diverse operating requirements.

Wear- and fatigue-resistant surfaces: Heat treatment and precision casting processes significantly enhance component lifespan and reliability.

Through the precision casting process, key components of the coupling, such as flanges and gear sleeves, can achieve high strength and high precision, meeting the long-term stable operation requirements in high-speed and high-torque environments.

Flexible material selection: A variety of high-performance materials, including ductile iron, alloy steel, carbon steel, and stainless steel, can be used to meet diverse operating requirements.

Wear- and fatigue-resistant surfaces: Heat treatment and precision casting processes significantly enhance component lifespan and reliability.

Through the precision casting process, key components of the coupling, such as flanges and gear sleeves, can achieve high strength and high precision, meeting the long-term stable operation requirements in high-speed and high-torque environments.

Casting Materials and Process Characteristics

Commonly used casting materials in coupling manufacturing include:

Ductile Iron

High cost performance, good shock resistance, suitable for medium and low voltage systems.

Carbon Steel (A105)

It has excellent comprehensive performance and is suitable for general pressure piping systems.

Alloy Steel (A182 F11/F22)

It has excellent comprehensive performance and is suitable for general pressure piping systems.

Stainless Steel (304/316)

It has strong corrosion resistance and is suitable for marine and chemical media environments.

Common casting processes are:

Sand Casting: Cost-effective and suitable for large-sized industrial coupling parts.

Investment Casting: Delivers high-precision, complex shapes and tight tolerances.

Die Casting: Ensures high-strength, stable components for demanding operational environments.

Sand Casting: Cost-effective and suitable for large-sized industrial coupling parts.

Investment Casting: Delivers high-precision, complex shapes and tight tolerances.

Die Casting: Ensures high-strength, stable components for demanding operational environments.

What We Offer

Leierwo is committed to providing the highest quality precision metal parts manufacturing services, including precision casting, investment casting, sand casting, and CNC machining. We offer customized solutions and can complete your design within 3–5 weeks, depending on the complexity of the parts. Before mass production, we provide one free sample for testing and approval.

Investment Casting Service

Features: Investment casting has high precision, can adapt to complex shapes, has smooth surface and little material waste.

Applications: aerospace, precision machinery, automobiles, medical equipment, etc.

Sand Casting Service

Features: It uses sand mold, which is low in cost and suitable for large and complex-shaped metal castings.

Applications: automotive parts, mechanical structural parts, large castings.

Our Casting Services – Fufilled Across Metal Grades

Leierwo possesses extensive expertise across a wide range of alloy grades, enabling our customers to select the ideal materials to optimize their products and meet the most demanding global application requirements. Feel free to explore the alloy series listed below to find the perfect match for your specific needs.

We Provide Comprehensive Manufacturing Solutions

Investment Casting

Sand Casting

3D Printing

Stainless Steel Castings

Carbon Steel Castings

Alloy Steel Castings

Start Your Project with Leierwo

1. Submit Your Inquiry

Send your CAD drawings and 3D files via email, specifying material grade, order quantity, surface finish, or any other relevant details.

2. Cost Calculation

Once we receive your design, our engineering team will carefully evaluate the drawings and calculate the price based on actual production costs as soon as possible.

3. Start Production

Upon pricing approval, our production team will prepare the materials and schedule production promptly.Leierwo always ensures on-time delivery.

4. Arrange Delivery

After production is completed, we will provide packaging details and arrange shipment via sea or air. We support global shipping for every order.

FAQ

Q1. Are you a trading company or a manufacturer?

Q2. Can you quote based on 3D drawings?

Q3. How do you handle RFQs (Request for Quotation)?

Q4. What is your typical lead time?

Q5. Do you provide samples? Are they free?

Q6. What payment methods do you accept?

Q7. How do you ensure quality control?

Q8. Do your products come with a warranty?

Q9. How do you view your relationship with customers?