Copper and Its Alloys

Copper and its alloys are widely used in precision casting, boasting excellent electrical and thermal conductivity, corrosion resistance, and high strength. Their superior casting properties make them an ideal choice for many high-precision, high-performance components. Copper alloys play a vital role in many industrial sectors, particularly those requiring high electrical conductivity and wear resistance, such as the electronics, automotive, and energy industries.

In precision casting, copper and its alloys are commonly used to produce complex, high-precision, and high-temperature resistant components. The advantages of copper alloys lie in their excellent mechanical properties and corrosion resistance, which ensure long-term stability and reliability, making them particularly suitable for applications requiring high performance and a long life.

In precision casting, copper and its alloys are commonly used to produce complex, high-precision, and high-temperature resistant components. The advantages of copper alloys lie in their excellent mechanical properties and corrosion resistance, which ensure long-term stability and reliability, making them particularly suitable for applications requiring high performance and a long life.

Common Material Grades of Copper and Its Alloys

| Alloy Grade | Alloy Name | Material Properties | Application Industry | Sample Widget |

| Cu-ETP (C11000) | Electrolytic Copper | Good electrical conductivity, thermal conductivity, high ductility, strong corrosion resistance | Electronics, precision instruments, air conditioners, heat exchangers | Electrical contacts, heat exchanger tubes, terminal blocks |

| Cu-Zn (Brass) | H59, H62, H63 | Good mechanical properties, high strength and corrosion resistance, easy to process | Precision casting, automobiles, mechanical parts, ships | Gears, valves, pump bodies, mechanical connectors |

| Cu-Sn (Bronze) | H70, H80, H90 | Excellent wear and corrosion resistance, good elasticity and strength | Shipbuilding, engineering machinery, military | Guide rails, springs, castings |

| Cu-Ni (Aluminum Bronze) | C61500, C63000 | Excellent wear resistance and corrosion resistance, especially in seawater corrosion environment | Shipbuilding, marine engineering, and nuclear industry | Seawater pumps, ship propellers, corrosion-resistant components |

| Cu-Al (Aluminum Bronze) | CAl5, CAl10 | High strength, good corrosion resistance, strong high temperature resistance | Aerospace, automotive, high temperature engineering | Turbine blades, valves, engine parts |

| Cu-Sn-Pb (Lead Bronze) | C93200, C93600 | Good self-lubricating performance, wear resistance, suitable for high load work | Machinery, metallurgy, papermaking | Bearings, sliders, gears |

| Cu-Ag (Silver-Copper Alloy) | C17500 | High electrical conductivity, excellent weldability and oxidation resistance | High-precision electronic equipment and communication equipment | High-frequency components, electrical contacts, and ultra-high-frequency components |

Copper and Its Alloy Casting Technology

Sand Casting

Applicable copper alloys: brass (Cu-Zn), bronze (Cu-Sn), aluminum bronze (Cu-Al)

Features:Moderate Cost: Sand casting is a relatively low-cost process suitable for medium-volume production.

High Adaptability: Suitable for casting complex geometries and larger components.

Wide Material Selection: Suitable for a variety of copper alloys, offering significant advantages in medium-volume production.

High Adaptability: Suitable for casting complex geometries and larger components.

Wide Material Selection: Suitable for a variety of copper alloys, offering significant advantages in medium-volume production.

Suitable for: Medium-volume production and large-size castings, especially for cost-sensitive projects.

Suitable for medium-sized components in industries such as automotive and machinery.

Suitable for medium-sized components in industries such as automotive and machinery.

Recommended components: Gears, pumps, valves, mechanical connectors, ship components, etc.

Investment Casting

Applicable copper alloys: electrolytic copper (Cu-ETP), bronze (Cu-Sn), aluminum bronze (Cu-Al), lead bronze (Cu-Sn-Pb)

Features: High Precision: Suitable for parts requiring complex shapes and high dimensional accuracy.

Excellent Surface Quality: Investment casting can achieve a high surface finish, reducing the need for subsequent machining.

Material Flexibility: A wide range of copper and its alloys can be cast, including high-strength and high-corrosion-resistant alloys.

Excellent Surface Quality: Investment casting can achieve a high surface finish, reducing the need for subsequent machining.

Material Flexibility: A wide range of copper and its alloys can be cast, including high-strength and high-corrosion-resistant alloys.

Applications: Production of high-precision parts, such as aerospace, high-end automotive components, and precision instruments.

Suitable for casting small batches and complex shapes.

Suitable for casting small batches and complex shapes.

Recommended Components: High-precision electronic contacts, guide rails, springs, marine components, etc.

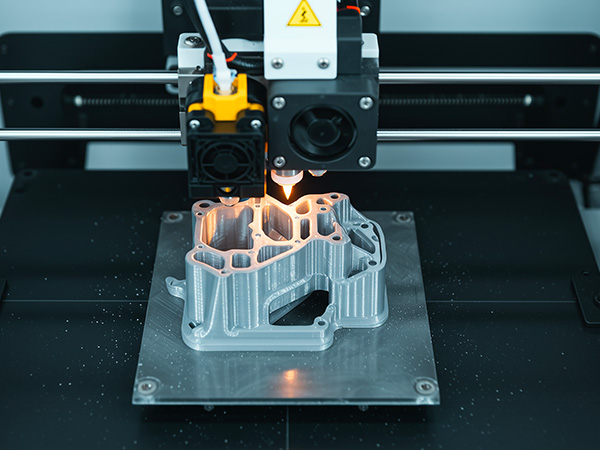

3D Printing

Applicable copper alloys: electrolytic copper (Cu-ETP), aluminum bronze (Cu-Al)

Features: Rapid Prototyping: 3D printing is suitable for prototypes and small-batch production, enabling rapid design, adjustment, and optimization.

Complex Geometries: 3D printing can cast complex designs that are difficult to achieve with traditional methods.

High Precision: 3D printing can achieve extremely high geometric accuracy, making it suitable for customization and small-batch production.

Complex Geometries: 3D printing can cast complex designs that are difficult to achieve with traditional methods.

High Precision: 3D printing can achieve extremely high geometric accuracy, making it suitable for customization and small-batch production.

Applicable Scenarios: Small-batch custom production, especially for parts requiring complex shapes or high precision.

High-end manufacturing, scientific research prototype development, aerospace, and electronic equipment.

High-end manufacturing, scientific research prototype development, aerospace, and electronic equipment.

Recommended Parts: Electronic components, complex piping, precision instrument accessories, customized parts, etc.

Welding

Applicable copper alloys: Most copper alloys, such as electrolytic copper (Cu-ETP), bronze (Cu-Sn)

Features: Suitable for metal joining: Welding is suitable for processes requiring the joining of dissimilar parts or repairs, and is particularly well-suited for joining large parts.

Lower precision requirements: Welding is not typically used for complex single-part castings, but rather for the joining of multiple parts.

Lower precision requirements: Welding is not typically used for complex single-part castings, but rather for the joining of multiple parts.

Applications: Suitable for mass welding and repair of parts, especially metal structures involving copper alloys.

Suitable for connecting structural components in machinery, construction, energy, and other fields.

Suitable for connecting structural components in machinery, construction, energy, and other fields.

Recommended components:Mechanical structural parts, equipment frames, heat exchanger components, etc.

Start Your Project with Leierwo

1. Submit Your Inquiry

Send your CAD drawings and 3D files via email, specifying material grade, order quantity, surface finish, or any other relevant details.

2. Cost Calculation

Once we receive your design, our engineering team will carefully evaluate the drawings and calculate the price based on actual production costs as soon as possible.

3. Start Production

Upon pricing approval, our production team will prepare the materials and schedule production promptly.Leierwo always ensures on-time delivery.

4. Arrange Delivery

After production is completed, we will provide packaging details and arrange shipment via sea or air. We support global shipping for every order.

FAQ

Q1. Are you a trading company or a manufacturer?

Q2. Can you quote based on 3D drawings?

Q3. How do you handle RFQs (Request for Quotation)?

Q4. What is your typical lead time?

Q5. Do you provide samples? Are they free?

Q6. What payment methods do you accept?

Q7. How do you ensure quality control?

Q8. Do your products come with a warranty?

Q9. How do you view your relationship with customers?