Why Stainless Steel CNC Machining Services Deliver Unmatched Precision

Table of Contents

Introduction

In today’s manufacturing industry, precision is key. When it comes to producing high-quality parts, especially in industries like aerospace, automotive, medical, and electronics, stainless steel CNC machining services stand out as a reliable solution. These services leverage cutting-edge technology to achieve remarkable accuracy in every project. But what makes stainless steel CNC machining services so precise? This blog delves into the reasons behind their unmatched precision, exploring the processes, equipment, materials, and techniques that ensure top-tier results.

What Are Stainless Steel CNC Machining Services?

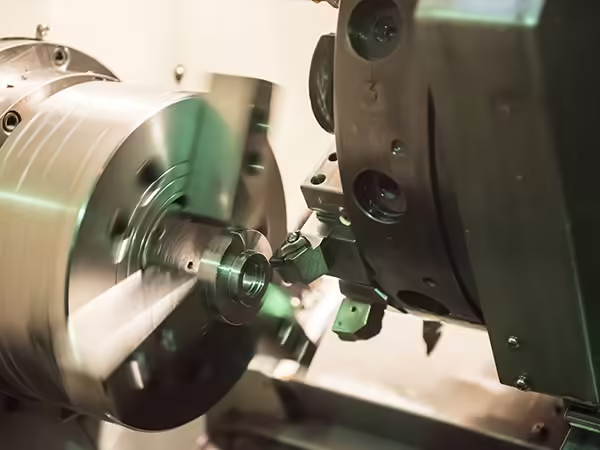

Before diving into the specifics of their precision, let’s first understand what stainless steel CNC machining services entail. CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed software controls the movement of tools and machinery. In stainless steel machining, this process is used to cut, shape, and finish stainless steel components with extreme accuracy.

The key to precision in CNC machining lies in the controlled environment in which these services are provided. CNC machines, which include lathes, mills, and drills, are programmed with high-level software to execute complex designs and geometries, with minimal human intervention.

Why Choose Stainless Steel for CNC Machining?

Stainless steel is one of the most commonly used materials for CNC machining due to its combination of strength, corrosion resistance, and versatility. When used in CNC machining, stainless steel offers several advantages:

- Durability: Stainless steel components are known for their resistance to rust and corrosion, making them ideal for parts that will be exposed to harsh environments.

- Strength: The material provides excellent strength-to-weight ratio, making it suitable for high-performance applications.

- Aesthetic Appeal: Stainless steel parts often have a clean, polished finish, which is important in industries where appearance matters.

The high demand for stainless steel CNC machining services stems from the material’s ability to meet rigorous standards for durability and precision.

Key Features of Stainless Steel CNC Machining Services

Several factors contribute to the precision of stainless steel CNC machining services. Let’s take a look at the main elements that ensure these services deliver the highest accuracy:

1. Advanced CNC Technology

The foundation of precision in stainless steel CNC machining services is the use of state-of-the-art CNC machines. These machines operate based on precise, pre-programmed instructions. With the capability to repeat the same action thousands of times without deviation, they ensure that each part is made to exact specifications.

2. Skilled Operators

While CNC machines perform most of the work automatically, skilled operators are essential to oversee the process. They monitor the operation, make adjustments as necessary, and ensure that the machines are functioning correctly. A well-trained operator can catch potential issues before they become major problems, adding a layer of human expertise to the precision process.

3. Material Control

The choice of material plays a huge role in the outcome of the final product. Stainless steel is known for its ability to withstand high levels of stress and heat. In CNC machining, the quality of the stainless steel used can significantly affect the precision of the final piece. Premium-quality stainless steel alloys allow for cleaner cuts and better surface finishes, which result in higher precision.

4. Tight Tolerances

The primary reason why stainless steel CNC machining services are so precise is their ability to produce parts within tight tolerances. Tolerances are the acceptable variations in the dimensions of a manufactured part. CNC machines can achieve tolerances as tight as ±0.0001 inches, ensuring that the parts are accurate and fit perfectly into the intended assembly.

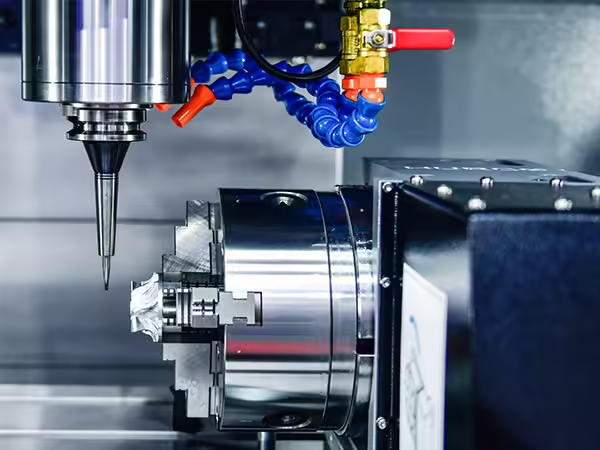

5. Multi-Axis Machining

Modern CNC machines often feature multiple axes of motion, which provide a significant advantage when working with complex designs. Multi-axis machining allows for more intricate cuts and shapes, which would be difficult or impossible with traditional manufacturing methods. This capability is crucial for stainless steel CNC machining services, where parts often have highly complex geometries.

Table: Comparison of CNC Machining Tolerances

| Machine Type | Precision Level (Tolerances) | Applications |

|---|---|---|

| 3-Axis CNC | ±0.001 inches | Basic parts, simple geometries |

| 4-Axis CNC | ±0.0005 inches | Complex shapes, moderate precision |

| 5-Axis CNC | ±0.0001 inches | High precision parts, aerospace, medical |

| Swiss CNC | ±0.0001 inches | Small, intricate parts, high precision |

The Role of Software in CNC Machining Precision

Another critical component that contributes to the unmatched precision of stainless steel CNC machining services is the sophisticated software used to control the machines. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software are used to design and simulate the machining process before it even begins.

1. CAD and CAM Integration

CAD software allows engineers to design detailed 3D models of parts, while CAM software translates those designs into instructions that the CNC machine can understand. The integration of CAD and CAM ensures that every aspect of the part is planned out with precision, and any potential issues are detected early in the process.

2. Real-Time Monitoring and Adjustments

Advanced CNC machines also incorporate real-time monitoring systems. These systems track the machining process and automatically make adjustments if the part starts deviating from the specified dimensions. This real-time feedback loop further enhances precision, ensuring that the part is manufactured correctly the first time.

Applications of Stainless Steel CNC Machining Services

Due to its precision, stainless steel CNC machining services are widely used across many industries. Some of the most common applications include:

- Aerospace: Aerospace components demand extreme precision, and stainless steel is often used for critical parts like turbine blades and engine components.

- Medical: Stainless steel is commonly used in medical devices such as surgical tools, implants, and diagnostic equipment.

- Automotive: Automotive parts, including engine components, exhaust systems, and fasteners, require the strength and precision that CNC machining can provide.

- Electronics: Precision parts used in electronics, such as connectors and housings, often rely on CNC machining to meet the tight tolerances required for modern technology.

Why Precision Matters in Stainless Steel CNC Machining

Precision is not just a matter of accuracy—it’s about ensuring that the final product functions correctly and performs as intended. Parts with tight tolerances fit better, perform better, and last longer. For industries like aerospace and medical devices, even the smallest deviation can have catastrophic consequences. This is why stainless steel CNC machining services are trusted to deliver such high precision.

Conclusion

In conclusion, stainless steel CNC machining services offer unmatched precision due to the combination of advanced technology, skilled operators, high-quality materials, and tight tolerances. Whether you’re working in aerospace, automotive, or medical industries, the precision offered by CNC machining is essential for producing parts that meet exacting standards. By choosing stainless steel, manufacturers are assured of a durable, high-performance material that can withstand rigorous conditions while maintaining the accuracy required for optimal performance.

FAQ

What is the main advantage of stainless steel for CNC machining?

The primary advantage of stainless steel in CNC machining lies in its exceptional combination of strength, corrosion resistance, and versatility. Stainless steel is known for its robustness, which makes it suitable for producing high-strength components that need to withstand heavy stresses. The corrosion resistance of stainless steel ensures that the parts retain their integrity, even when exposed to harsh environments such as high humidity, heat, or chemicals. This makes stainless steel ideal for industries like aerospace, automotive, medical devices, and food processing, where durability and reliability are paramount. Additionally, stainless steel can be easily machined to achieve a smooth, polished surface, which is crucial for applications that require both functional and aesthetic precision.

How tight can the tolerances be in stainless steel CNC machining services?

CNC machines are capable of achieving extremely tight tolerances, often as small as ±0.0001 inches. This level of precision allows manufacturers to produce parts that fit together perfectly without the need for further adjustments or rework. For example, a tolerance of ±0.0001 inches ensures that even highly intricate components maintain their exact dimensions, ensuring proper function in high-performance applications. Tight tolerances are essential for industries like aerospace, medical devices, and electronics, where even the slightest variation can affect the performance, safety, or reliability of a part. CNC machines achieve this precision by utilizing advanced programming and high-quality tooling, which work in concert to minimize error and maintain consistency throughout the machining process.

What industries use stainless steel CNC machining services?

Stainless steel CNC machining services are used across a wide variety of industries where precision, durability, and high performance are required. Some of the most prominent industries include:

- Aerospace: In aerospace, CNC-machined stainless steel parts are used in critical components such as turbine blades, engine housings, and airframe parts. These parts require exceptional strength and resistance to extreme temperatures, making stainless steel an ideal material.

- Medical: The medical industry relies on CNC machining to produce surgical tools, implants, and diagnostic equipment. Stainless steel’s biocompatibility and corrosion resistance make it ideal for devices that will come into contact with the human body, ensuring safety and longevity.

- Automotive: The automotive industry uses stainless steel CNC machining for parts like engine components, exhaust systems, and fasteners. Stainless steel’s strength and corrosion resistance are essential for ensuring the reliability and performance of these parts under demanding conditions.

- Electronics: Precision components for electronics, such as connectors, housings, and sensors, often rely on stainless steel CNC machining. The material’s ability to handle delicate components while maintaining structural integrity makes it perfect for high-tech applications where precision is key.

In all of these industries, stainless steel CNC machining services are vital for producing components that need to meet high standards for performance and reliability.

Why is CNC machining considered more precise than traditional machining?

CNC machining is regarded as more precise than traditional machining due to its automation and computer control. Unlike conventional machining, where the operator must manually adjust the machine and monitor each cut, CNC machining relies on pre-programmed instructions that are executed with high consistency. These instructions are based on precise 3D models created in CAD software, ensuring that the machine performs the exact movements required for the job.

Additionally, CNC machines can operate continuously and with minimal human intervention, reducing the likelihood of errors caused by fatigue or inexperience. The level of repeatability offered by CNC technology allows manufacturers to produce thousands of identical parts with consistent quality. In contrast, traditional machining methods often suffer from slight variations due to the need for manual adjustments, making CNC machining far superior in terms of precision and consistency.

How does software contribute to CNC machining precision?

Software plays a crucial role in CNC machining by providing the foundation for designing, simulating, and executing the machining process. CAD (Computer-Aided Design) software allows engineers to create detailed 3D models of parts, specifying exact dimensions and geometries. This eliminates the risk of human error that could occur in traditional manual design processes. The digital model is then transferred to CAM (Computer-Aided Manufacturing) software, which generates the necessary machine code to guide the CNC machine’s actions.

The integration of CAD and CAM ensures that the machining process is both efficient and precise. With the CAD model as the blueprint, the CAM system optimizes the path and cutting speeds for the machine to follow. The use of advanced algorithms in CAM software ensures that the machine’s movements are as efficient as possible, reducing waste and time while maximizing precision.

Moreover, many modern CNC machines are equipped with real-time monitoring software, which continuously tracks the machining process and makes adjustments as necessary. If any discrepancies arise, the software can automatically correct them, further enhancing the precision of the operation.

Stay Connected with Us

Thank you for reading! We hope this blog provided you with valuable insights and inspiration on acoustic panel ceilings. If you enjoyed the content and want to stay updated with the latest trends, tips, and behind-the-scenes updates, we’d love to connect with you on social media.

📘 Follow us on Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Join our growing community where we share expert advice, product highlights, and interactive discussions with professionals and design enthusiasts from around the world.

Let’s keep the conversation going—see you there!

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF