What is 1020 Carbon Steel? A Comprehensive Guide

Table of Contents

Introduction

1020 carbon steel is a low-to-medium carbon steel that is commonly used in a wide range of manufacturing and engineering applications. It has a carbon content of approximately 0.20%, which places it in the category of mild steel. Despite its low carbon content, 1020 steel offers excellent weldability, machinability, and surface hardening properties. These characteristics make it a versatile material in the production of many industrial components.

In this blog, we will dive into the details of 1020 carbon steel, exploring its properties, advantages, common applications, and its specific uses in the casting industry. By the end of this article, you’ll have a comprehensive understanding of why 1020 carbon steel is such an essential material in modern manufacturing and engineering.

What is 1020 Carbon Steel?

1020 carbon steel is a part of the SAE (Society of Automotive Engineers) classification system for steel grades. It contains 0.20% carbon, which is relatively low compared to other steels with higher carbon content, such as 1045 or 1060 steels. The lower carbon content makes 1020 steel more malleable and easier to shape and weld. However, it still provides moderate strength and hardness, making it an excellent choice for applications that do not require extreme strength or wear resistance.

The chemical composition of 1020 steel typically includes:

- Carbon (C): 0.18 – 0.23%

- Manganese (Mn): 0.30 – 0.60%

- Phosphorus (P): 0.04% max

- Sulfur (S): 0.05% max

This composition gives 1020 carbon steel its unique balance of machinability, strength, and formability. It’s often chosen for applications that require good weldability, moderate strength, and ease of forming.

Key Properties of 1020 Carbon Steel

Strength and Hardness

1020 carbon steel offers a balance between strength and flexibility, making it an ideal choice for applications requiring moderate load-bearing capacity without the need for high-strength properties. The material is classified as a mild steel due to its relatively low carbon content, which typically ranges from 0.18% to 0.23%. This carbon percentage allows the steel to achieve adequate strength for various industrial uses.

The tensile strength of 1020 steel typically falls between 350 MPa and 480 MPa (50,000 to 70,000 psi), which makes it suitable for medium-duty applications where parts will be subjected to moderate stresses and loads. While 1020 carbon steel does not achieve the high strength levels seen in medium- or high-carbon steels, it still serves well in applications where cost-effectiveness and ease of fabrication are prioritized.

When in its normal annealed state, 1020 steel has a Brinell hardness rating of about 120 to 160 HB (Hardness Brinell), which provides a balance between ease of machining and sufficient resistance to wear. However, the hardness of 1020 steel can be increased by heat treatments, such as carburizing or induction hardening, which involve introducing carbon to the surface of the steel and heating it to high temperatures. These treatments improve the wear resistance and surface hardness, making the material more suitable for parts exposed to moderate friction and abrasion.

While the material doesn’t provide the extreme hardness needed for heavy-duty or high-wear environments, it is an excellent option for applications where the strength-to-weight ratio and toughness are more important than maximum hardness.

Workability and Machinability

One of the most notable characteristics of 1020 carbon steel is its exceptional machinability. Unlike higher-carbon steels, which tend to be harder and more challenging to machine, 1020 steel’s relatively low carbon content allows it to be easily turned, drilled, milled, and shaped. This ease of machining is highly advantageous for manufacturers who need to produce components with tight tolerances, as it reduces tool wear and machining time.

The soft nature of 1020 steel makes it highly formable, which means it can be bent, shaped, and drawn into various forms without risking cracking or breaking. This makes it ideal for manufacturing components that require customization after production, such as parts that need to be shaped into non-standard or complex geometries. Whether producing components in sheet, plate, or bar form, 1020 carbon steel can be readily worked into the desired shape using basic equipment like press brakes, benders, or rolling machines.

Additionally, the material’s excellent machinability ensures that it is a cost-effective choice for producing large volumes of components. High-speed machining operations can be performed without excessive tool wear, and parts can be made with fewer steps, reducing the overall cost of manufacturing.

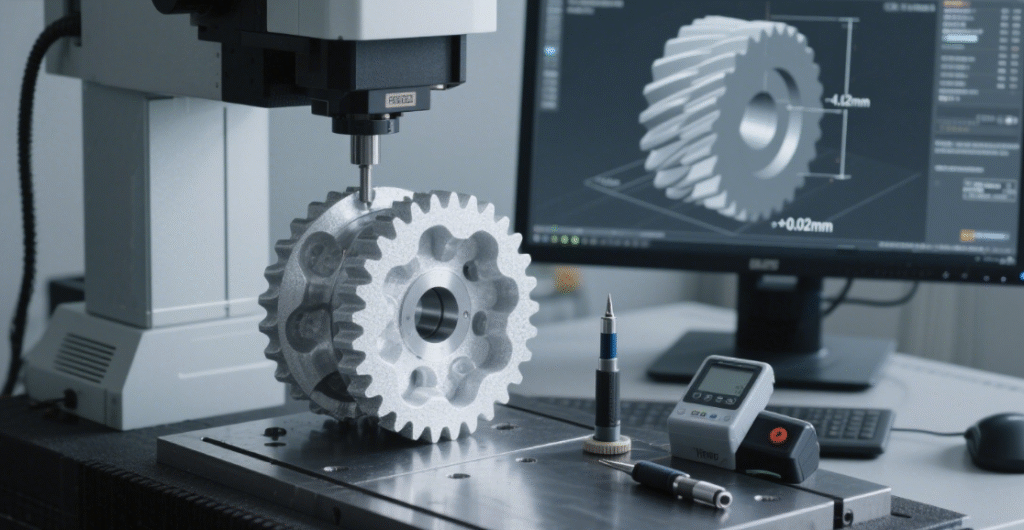

Because of these properties, 1020 steel is commonly used in the manufacturing of precision components, such as gears, shafts, and other mechanical parts that require detailed shaping or modifications post-production.

Weldability

Another standout feature of 1020 carbon steel is its weldability. Thanks to its low carbon content, 1020 steel is highly resistant to cracking during the welding process. This is crucial for applications where structural integrity must be maintained after the steel is welded into a new form. The material can be welded using MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and Stick welding techniques, which makes it suitable for a variety of industrial fabrication processes.

The reduced risk of cracking is primarily due to the low carbon content in 1020 steel, which means that it has a lower tendency to form brittle zones in the welded joint. In addition to preventing cracking, 1020 steel also produces clean welds with good penetration and bonding strength, making it ideal for producing welded components such as frames, brackets, structural supports, and other fabricated parts.

While 1020 steel’s weldability is excellent, it’s still essential to pay attention to welding parameters such as heat input and cooling rates. Too much heat can cause distortion or affect the final mechanical properties, so preheating the material before welding and controlling the cooling rate after welding may be necessary for thicker sections.

Because of its ease of welding and good overall performance in welding operations, 1020 is often used in industries like construction, automotive manufacturing, and heavy equipment production, where structural components are often required to be welded for further fabrication.

Corrosion Resistance

While 1020 carbon steel offers several advantages in terms of machinability, weldability, and workability, it does not naturally resist corrosion as well as alloyed steels like stainless steel. 1020 steel is highly susceptible to rusting and corrosion when exposed to moisture, oxygen, and other corrosive elements. This makes it unsuitable for environments where the material will be exposed to high humidity or other corrosive conditions unless additional protective measures are taken.

However, corrosion resistance can be significantly improved through various surface treatments. One of the most common methods for protecting 1020 steel from corrosion is galvanization, where the steel is coated with a layer of zinc. Galvanizing provides an effective barrier against moisture and oxygen, which prevents rust from forming on the steel’s surface.

Other protective coatings that can improve corrosion resistance include painting or powder coating, which can be applied to the steel to provide an additional protective layer. For more demanding applications, corrosion-resistant alloys or protective surface treatments, such as phosphating or chrome plating, may also be employed.

While 1020 carbon steel will not naturally withstand exposure to harsh environments, these surface treatments make it a cost-effective material for use in environments where corrosion protection is needed but stainless steel would be too expensive.

In applications where corrosion is a concern, it is crucial to consider the environmental conditions and apply the appropriate corrosion protection to extend the life of the components made from 1020 carbon steel.

Applications of 1020 Carbon Steel

1020 carbon steel is widely used in many industries due to its versatility and cost-effectiveness. Some of the most common applications of 1020 steel include:

- Shafts and Axles: 1020 steel is often used in the manufacturing of shafts, including motor shafts, pump shafts, and hydraulic shafts. Its ability to handle moderate stress and its excellent machinability make it ideal for these applications.

- Mechanical Parts: This steel is commonly used for making mechanical parts such as gears, sprockets, bushings, and couplings. Its moderate strength and formability ensure that it can be easily shaped into complex parts.

- Automotive Components: 1020 carbon steel is used in the automotive industry for producing various parts such as steering components, suspension parts, and transmission components.

- Structural Components: It is also used in structural applications, such as frames and brackets, where moderate strength is required but the material needs to be easy to weld and fabricate.

- Cold Worked Parts: 1020 is ideal for parts that require cold working, such as cold drawn bars, because of its good surface hardening properties.

1020 Carbon Steel in the Casting Industry

In the casting industry, 1020 carbon steel is widely used due to its ability to undergo surface hardening processes, which makes it an ideal material for producing parts that need moderate wear resistance. This steel is commonly used in sand casting and die casting processes, where it is shaped into intricate components.

Some applications in the casting industry include:

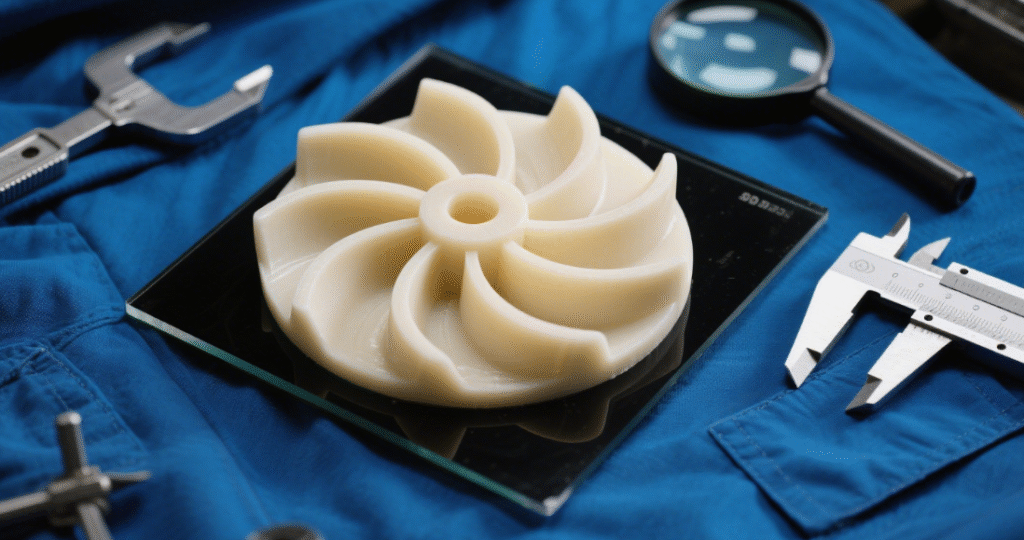

- Pump Components: Parts such as pump shafts and impellers benefit from 1020 carbon steel’s surface hardening properties, which provide them with the necessary wear resistance while maintaining machinability.

- Machine Components: Parts like gears, bushings, and bearings are often cast using 1020 steel. The steel’s ability to be easily machined after casting allows for precise fitting and high-quality components.

- Automotive Castings: In the automotive sector, 1020 carbon steel is frequently used in casting components that need to withstand moderate mechanical stress, such as steering gears and suspension components.

Table: Key Properties and Applications of 1020 Carbon Steel

| Property | Details |

|---|---|

| Carbon Content | 0.18% – 0.23% |

| Tensile Strength | 350 – 480 MPa (50,000 – 70,000 psi) |

| Hardness | 120 – 160 HB |

| Machinability | Excellent for machining and forming |

| Weldability | Very good, low risk of cracking |

| Applications | Shafts, gears, automotive parts, structural components |

| Corrosion Resistance | Moderate, requires coatings or treatments |

| Casting Suitability | Suitable for sand and die casting processes |

Advantages of 1020 Carbon Steel

- Cost-Effective: Compared to higher-carbon steels, 1020 is relatively inexpensive, making it a cost-effective choice for manufacturers.

- Good Weldability: Its excellent weldability makes it an ideal choice for projects requiring welding, such as fabricating parts and structures.

- Versatile: 1020 carbon steel is highly versatile, suitable for a wide range of applications from automotive components to structural elements.

- Easy to Machine: The steel’s excellent machinability ensures that it can be shaped into precision components quickly and efficiently.

- Surface Hardening: 1020 steel can be easily surface-hardened, making it ideal for components that require moderate wear resistance.

Conclusion

1020 carbon steel is a versatile and cost-effective material widely used across various industries, including automotive, construction, and manufacturing. Its combination of moderate strength, excellent weldability, machinability, and surface hardening properties makes it an ideal choice for a wide range of applications. Whether you are producing shafts, gears, or structural components, 1020 carbon steel offers a reliable and affordable solution for your manufacturing needs. By understanding its properties and applications, you can make informed decisions about when and how to use this valuable material in your projects.

FAQ

What is the difference between 1020 steel and 1018 steel?

Both 1020 and 1018 steels are low-carbon steels, but 1020 has slightly higher carbon content (0.20%) compared to 1018 (0.18%). This slight difference in carbon content gives 1020 a slightly higher strength and hardness, though both steels offer excellent machinability and weldability.

Is 1020 carbon steel hardenable?

Yes, 1020 carbon steel can be hardened using surface hardening techniques, such as carburizing or induction hardening. This allows for increased wear resistance in parts that are exposed to friction or mechanical stress.

Can 1020 steel be welded?

Yes, 1020 steel has excellent weldability and can be welded using common welding methods, including MIG, TIG, and Stick welding. Its low carbon content reduces the risk of cracking during the welding process.

What industries use 1020 carbon steel?

1020 carbon steel is used across many industries, including automotive, manufacturing, construction, and machinery. It is commonly used for components such as shafts, gears, and structural parts.

Is 1020 steel resistant to corrosion?

While 1020 steel is not naturally corrosion-resistant, it can be protected through coatings like galvanizing or painting. For applications exposed to harsh conditions, additional surface treatments may be required.

Stay Connected with Us

Thank you for reading! We hope this blog provided you with valuable insights and inspiration on acoustic panel ceilings. If you enjoyed the content and want to stay updated with the latest trends, tips, and behind-the-scenes updates, we’d love to connect with you on social media.

📘 Follow us on Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Join our growing community where we share expert advice, product highlights, and interactive discussions with professionals and design enthusiasts from around the world.

Let’s keep the conversation going—see you there!

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF