Titanium and Its Alloys

Titanium and its alloys are widely used in precision casting due to their exceptional strength, lightness, and corrosion resistance. Titanium alloys offer excellent resistance to high temperatures and oxidation, performing exceptionally well in extreme environments and withstanding high temperatures, pressures, and severe corrosive loads. They are particularly well-suited for the aerospace, medical, chemical, and energy industries, often used to manufacture critical components such as aircraft structures, engine parts, and medical implants.

In precision casting, titanium alloys are typically produced using investment casting or sand casting, enabling the production of complex shapes and high-precision castings. The exceptional properties of titanium alloys make them ideal for high-performance applications, ensuring long-term stability and durability in demanding operating environments. In the aerospace sector in particular, titanium alloys’ lightweight and corrosion resistance make them an ideal material choice.

Through advanced casting processes and rigorous quality control, we ensure that every titanium casting possesses exceptional precision, strength, and durability. Whether it’s a complex precision component or a large structural piece, our titanium castings can be tailored to your specific needs, providing reliable solutions for a wide range of high-end applications.

In precision casting, titanium alloys are typically produced using investment casting or sand casting, enabling the production of complex shapes and high-precision castings. The exceptional properties of titanium alloys make them ideal for high-performance applications, ensuring long-term stability and durability in demanding operating environments. In the aerospace sector in particular, titanium alloys’ lightweight and corrosion resistance make them an ideal material choice.

Through advanced casting processes and rigorous quality control, we ensure that every titanium casting possesses exceptional precision, strength, and durability. Whether it’s a complex precision component or a large structural piece, our titanium castings can be tailored to your specific needs, providing reliable solutions for a wide range of high-end applications.

Common Material Grades of Titanium and Its Alloys

| Alloy Grade | Alloy Name | Material Properties | Application Industry | Sample Widget |

| Titanium Alloy | Ti-6Al-4V | Excellent strength-to-weight ratio, good corrosion resistance, especially suitable for the manufacture of high-strength, lightweight structural parts | Aerospace, medical, automotive, precision casting | Aircraft structural parts, aircraft engine components, medical implants (such as joint prostheses) |

| Ti-5Al-2.5Sn | High strength and excellent welding performance, good oxidation resistance and high temperature resistance | Aerospace, marine engineering, precision casting | Aircraft structural components, heat exchangers, gas turbine blades | |

| Titanium Alloy | Ti-6Al-4V ELI | A high-purity version of Ti-6Al-4V with improved ductility and biocompatibility, suitable for medical and high-precision applications | Medical, precision casting, aerospace | Medical implants (such as artificial bones), high-precision instrument parts |

| Titanium Alloy | Ti-3Al-2.5V | It has a good strength to toughness ratio and good corrosion resistance, and is suitable for structural parts with lower strength requirements. | Aerospace, marine engineering, precision casting | Aviation structures, ship components, chemical reactors |

| Titanium Alloy | Ti-6Al-2Sn-4Zr-6Mo | High strength, high temperature resistance, good corrosion resistance, suitable for components in high load and high temperature environments | Aerospace, energy, precision casting | Aircraft engine blades, jet engine components, gas turbine parts |

| Titanium Alloy | Ti-15V-3Cr-3Sn-3Al | High strength, excellent corrosion resistance, suitable for high temperature and corrosion resistant environments | Aerospace, energy, and chemical industries | High temperature structural components, heat exchangers, jet engine turbine blades |

| Pure Titanium | Grade 1 | Excellent corrosion resistance and processing properties, suitable for lightly loaded structural parts and applications requiring high biocompatibility | Chemical, medical, precision casting | Chemical equipment, medical implants (such as heart valves), ophthalmic devices |

| Grade 2 | Good strength and toughness, excellent corrosion resistance, widely used in fields requiring light load and high corrosion resistance | Medical, chemical, marine engineering, precision casting | Chemical reactors, seawater pipelines, aerospace components | |

| Titanium Alloy | Ti-8Al-1Mo-1V | With high strength and good ductility, it is suitable for parts requiring high strength and oxidation resistance | Aerospace, energy, precision casting | Aircraft structural parts, energy equipment, oil platform components |

Titanium and Its Alloy Casting Process

Investment Casting

Applicable alloys: Ti-6Al-4V, Ti-6Al-4V ELI, Ti-5Al-2.5Sn, Ti-6Al-2Sn-4Zr-6Mo

Features: High-Precision Casting: Investment casting offers exceptionally high precision, making it suitable for complex geometries.

Excellent Surface Quality: Suitable for castings requiring delicate surface treatments, minimizing subsequent machining.

Adaptability to Complex Shapes: Particularly well-suited for castings with complex internal structures, such as turbine blades and engine components.

Excellent Surface Quality: Suitable for castings requiring delicate surface treatments, minimizing subsequent machining.

Adaptability to Complex Shapes: Particularly well-suited for castings with complex internal structures, such as turbine blades and engine components.

Applications: Aerospace: Turbine blades and combustor components.

Energy: High-temperature alloy components and reactor parts.

Precision instruments: Components requiring high precision and strength.

Energy: High-temperature alloy components and reactor parts.

Precision instruments: Components requiring high precision and strength.

If you need to produce high-temperature alloy components or complex shapes, investment casting is the ideal choice

Sand Casting

Applicable alloys: Ti-3Al-2.5V, Ti-6Al-4V (especially in low-volume production)

Features: Large-size castings: Sand casting is capable of casting larger titanium alloy parts.

High production efficiency: Suitable for mass production of titanium alloy parts with relatively simple shapes, it can be produced in a shorter time.

Low cost: Compared to other high-precision casting processes, sand casting has lower production costs.

High production efficiency: Suitable for mass production of titanium alloy parts with relatively simple shapes, it can be produced in a shorter time.

Low cost: Compared to other high-precision casting processes, sand casting has lower production costs.

Applications: Marine Engineering: Ship components and seawater equipment.

Energy Industry: Large titanium alloy components, such as heat exchangers and pressure vessels.

Heavy Machinery: Large structural components and vessels.

Energy Industry: Large titanium alloy components, such as heat exchangers and pressure vessels.

Heavy Machinery: Large structural components and vessels.

If you need large-scale or simple-shaped titanium alloy castings, sand casting is an efficient and economical choice.

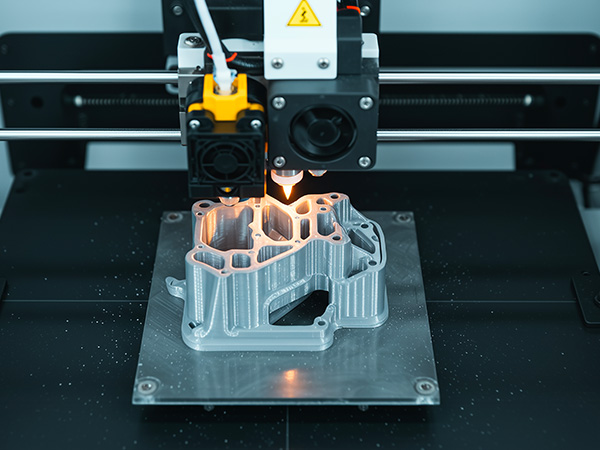

3D Printing

Applicable alloys: Ti-6Al-4V, Ti-6Al-4V ELI, Ti-5Al-2.5Sn

Features: Extremely high design freedom: 3D printing allows for the inclusion of complex geometries and structures in designs, enabling the creation of internal channels or pore structures that are impossible to achieve using traditional methods.

Rapid prototyping: Ideal for the rapid production of small batches of highly complex titanium alloy parts, especially in the early stages of product development.

Minimal material waste: Precisely controlling material usage reduces scrap, making it suitable for the production of small batches of high-value products.

Rapid prototyping: Ideal for the rapid production of small batches of highly complex titanium alloy parts, especially in the early stages of product development.

Minimal material waste: Precisely controlling material usage reduces scrap, making it suitable for the production of small batches of high-value products.

Applications: Aerospace: Complex engine components and structural parts, especially those with optimized designs.

Medical devices: Customized titanium alloy implants and personalized medical devices.

High-performance applications: High-precision, low-volume titanium alloy components.

Medical devices: Customized titanium alloy implants and personalized medical devices.

High-performance applications: High-precision, low-volume titanium alloy components.

If your needs are small-batch customization or rapid prototyping, 3D printing offers extreme flexibility and fast delivery capabilities.

Welding

Applicable alloys: Ti-6Al-4V, Ti-5Al-2.5Sn, Ti-6Al-2Sn-4Zr-6Mo

Features: High-Strength Connections: Titanium alloy welding can be used to connect dissimilar components, particularly in applications requiring high-strength joints.

High Precision: The welding process maintains high material strength and precision, making it suitable for high-end applications.

Suitable for Repair and Customization: The welding process can be flexibly adjusted for repairing existing components or custom production.

High Precision: The welding process maintains high material strength and precision, making it suitable for high-end applications.

Suitable for Repair and Customization: The welding process can be flexibly adjusted for repairing existing components or custom production.

Applications:

Energy: Welding of oil pipelines, heat exchangers, and reactor components.

Aerospace: Welding of aircraft structural components.

Medical Devices: Welding of medical device connectors requiring reinforcement.

Energy: Welding of oil pipelines, heat exchangers, and reactor components.

Aerospace: Welding of aircraft structural components.

Medical Devices: Welding of medical device connectors requiring reinforcement.

If your needs involve joining, custom production or repair of titanium alloy components, welding processes offer efficient and flexible solutions.

Forging

Applicable alloys: Ti-6Al-4V, Ti-15V-3Cr-3Sn-3Al

Features:High-strength material: Forging significantly enhances the mechanical properties of titanium alloys, making them particularly suitable for high-strength and high-load components.

Suitable for medium- and large-volume production: The forging process is well-suited for titanium alloy components subject to high loads and offers high production efficiency.

Good structural density: The forging process densifies the internal structure of titanium alloys, improving durability and fatigue resistance.

Suitable for medium- and large-volume production: The forging process is well-suited for titanium alloy components subject to high loads and offers high production efficiency.

Good structural density: The forging process densifies the internal structure of titanium alloys, improving durability and fatigue resistance.

Applications: Aerospace: High-strength turbine blades, engine components, and aircraft structures.

Energy: Pressure vessels, nuclear reactor components, and oil platform parts.

Automotive: High-performance vehicle body parts and engine components.

Energy: Pressure vessels, nuclear reactor components, and oil platform parts.

Automotive: High-performance vehicle body parts and engine components.

If you need to mass-produce high-strength, high-temperature resistant titanium alloy parts, forging is the ideal choice

Start Your Project with Leierwo

1. Submit Your Inquiry

Send your CAD drawings and 3D files via email, specifying material grade, order quantity, surface finish, or any other relevant details.

2. Cost Calculation

Once we receive your design, our engineering team will carefully evaluate the drawings and calculate the price based on actual production costs as soon as possible.

3. Start Production

Upon pricing approval, our production team will prepare the materials and schedule production promptly.Leierwo always ensures on-time delivery.

4. Arrange Delivery

After production is completed, we will provide packaging details and arrange shipment via sea or air. We support global shipping for every order.

FAQ

Q1. Are you a trading company or a manufacturer?

Q2. Can you quote based on 3D drawings?

Q3. How do you handle RFQs (Request for Quotation)?

Q4. What is your typical lead time?

Q5. Do you provide samples? Are they free?

Q6. What payment methods do you accept?

Q7. How do you ensure quality control?

Q8. Do your products come with a warranty?

Q9. How do you view your relationship with customers?