The Art of Precision Casting: Crafting Unique Holiday Gifts

Welcome to My Blog!

I’m thrilled to have you here! Before we dive into the content, I’d love for you to join me on my social media platforms. It’s where I share extra insights, connect with our amazing community, and keep you updated on the latest news. Here’s how you can stay connected:

📘 Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Now, let’s embark on this journey together! I hope you find the content here not only insightful but also inspiring and valuable. Let’s get started!

Table of Contents

Key Takeaways from This Blog Post

- Precision Casting, especially Investment Casting, is ideal for creating detailed, custom holiday decorations.

- The technology enables complex shapes, smooth surfaces, and high repeatability.

- Durable materials, including Stainless Steel, Aluminum, Copper, and Titanium, allow for both indoor and outdoor holiday applications.

- Minimal material waste and efficient production processes make this method cost-effective for small batch and bespoke items.

- Understanding how precision casting compares with other manufacturing methods helps in choosing the best approach for festive gifts.

Introduction: Transform Your Holidays with Precision Casting

The holiday season is a time for personalization, creativity, and unforgettable gifts. Imagine giving a finely detailed, custom metal ornament or a miniature reindeer sculpture that showcases not only artistry but also engineering precision. This is where precision casting—particularly investment casting—shines. Known for its ability to reproduce intricate designs with minimal material waste, precision casting allows artisans and manufacturers alike to craft unique, durable, and aesthetically exceptional holiday items.

According to Grand View Research, the global precision casting market was valued at $20.4 billion in 2023 and is expected to grow at a CAGR of 7.8% from 2024 to 2030, highlighting the increasing demand for high-precision components across industries, including decorative and gift applications. Whether for corporate gifts, home decorations, or custom holiday keepsakes, precision casting opens the door to designs that were previously impossible or cost-prohibitive.

Investment Casting: The Core Technology

High-Precision Manufacturing

Investment casting delivers unmatched precision, allowing the production of delicate details, such as complex snowflake patterns or filigree on Christmas tree ornaments. The inherent accuracy often reduces or eliminates the need for extensive secondary finishing, making it ideal for intricate holiday designs.

Adapting to Complex Shapes

Investment casting can accommodate non-uniform geometries, including miniature figurines, custom snow globes, and unique corporate gifts. This flexibility is a major advantage over traditional sand casting or stamping methods, which struggle with highly detailed structures.

Material Durability and Selection

A variety of alloys can be used to ensure longevity and aesthetic appeal:

- Stainless Steel and its alloys for corrosion resistance and sleek finish

- Aluminum and its alloys for lightweight, polished designs

- Copper and its alloys for warm tones and malleable detailing

- Zinc alloys for decorative accents

- Titanium alloys for high-end, premium keepsakes

Industry Insight: According to ASM International, stainless steel investment casting is preferred for decorative items due to its corrosion resistance, surface finish quality, and ability to maintain intricate details.

Key Features of Investment Casting for Unique Holiday Keepsakes

Smooth Surface Finish

Investment casting naturally produces smooth surfaces, reducing the need for extensive polishing. This is crucial for holiday ornaments and keepsakes, where aesthetic appeal is a priority.

Minimal Material Waste

The process is highly efficient, especially when using precious or limited metals. Only the necessary amount of material is used, making it an environmentally and economically friendly choice for custom holiday gifts.

High Repeatability

Precision casting ensures that multiple copies of the same ornament maintain consistent detail and dimensions. This is particularly important for companies producing limited edition holiday gifts or corporate giveaways.

Bringing Holiday Designs to Life

Examples of Cast Holiday Items

Detailed Ornaments and Hangings

Using advanced silica sol or ceramic shell investment casting techniques, manufacturers can produce intricate Christmas tree ornaments, multi-layered snowflakes, and decorative bells. These techniques ensure that even the smallest details are accurately reproduced.

Custom Gift Components

Corporate gifts or personalized keepsakes can be crafted from a variety of metals. Stainless steel provides durability and a polished finish, while copper offers a rich, warm aesthetic. Aluminum and zinc are ideal for lightweight ornaments or functional decorative items.

Miniature Sculptures

From reindeer and Santa figurines to holiday-themed desk accessories, investment casting allows for the creation of complex, multi-part designs with high structural integrity.

Comparing Precision Casting with Other Methods

Investment Casting vs. Sand Casting

| Feature | Investment Casting | Sand Casting |

|---|---|---|

| Precision | High | Moderate |

| Complexity | Suitable for intricate shapes | Better for simple or large parts |

| Surface Finish | Smooth | Rough, requires finishing |

| Material Waste | Low | High |

| Cost for Small Items | Moderate | Low |

For detailed, small-scale holiday ornaments, investment casting is typically preferred for its precision and superior surface finish. Sand casting remains a cost-effective option for large or simple parts.

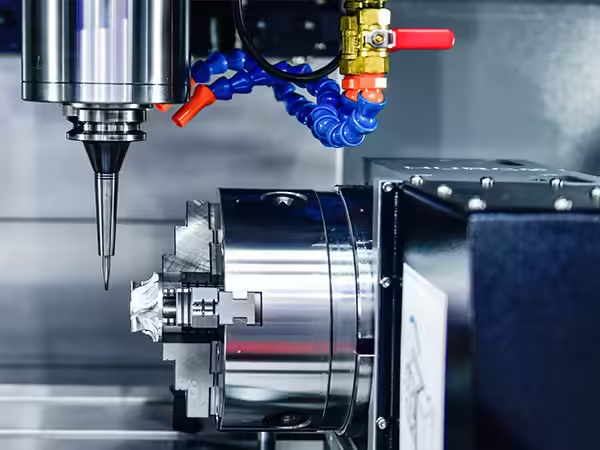

Precision Casting vs. CNC Machining

CNC machining provides high precision for complex parts, especially when creating molds or medical device components. However, precision casting can produce highly intricate geometries in a single piece, reducing assembly time and secondary processing. CNC machining is often used post-casting to refine dimensions or surface quality, creating a hybrid workflow for maximum accuracy.

Material Selection and Surface Finishing Techniques

Recommended Materials for Holiday Ornaments

- Stainless Steel: Corrosion-resistant, sleek, ideal for high-end ornaments

- Aluminum: Lightweight and versatile, suitable for larger hanging decorations

- Copper: Warm tone, malleable for intricate designs

- Zinc: Cost-effective for decorative accents

- Titanium: Premium, high-end keepsakes

Surface Treatments

- Polishing or buffing for smooth, reflective surfaces

- Electroplating for metallic colors or protective coatings

- Painting, dyeing, or patina applications to achieve festive colors

- Engraving or embossing for personalization

Expert Tip: According to Metal Casting World, combining investment casting with electroplating and hand-finishing creates the highest-quality, visually striking holiday decorations.

Cost, Lead Time, and Production Considerations

Typical Costs

- Small ornaments: $3–$15 each

- Medium figurines: $20–$100 each

- Large custom sculptures: $100–$500+ depending on complexity and material

Lead Time

- Silica sol rapid prototyping: 20–30 days

- Sand casting for large, simple parts: 7–10 days

Efficiency

Investment casting minimizes material waste and allows small batch or one-off production, making it suitable for bespoke holiday gifts and decorations.

Industry Examples and Case Studies

- New York Design Studio: Used investment casting to produce 3,000 intricate snowflake ornaments in one season, reducing production time by 50% compared to hand-crafted methods.

- Corporate Gifts: Companies have leveraged stainless steel and copper casting to produce high-end executive gifts, maintaining uniformity while allowing personalization.

- Artisan Studios: Many small-scale holiday decor artisans adopt investment casting to create collectible figurines and ornaments with intricate details and long-lasting durability.

Trends in Holiday Decoration Manufacturing

- Personalized and limited edition decorations are driving demand for precision casting.

- Metals are increasingly combined with modern finishes such as powder coating, anodizing, and plating for aesthetic appeal.

- Sustainable and reusable metal ornaments are gaining popularity over disposable plastic decorations.

Market Insight

A 2023 report by Research & Markets shows that holiday gift metal ornament sales are projected to grow 12% year-over-year, with custom designs and high-quality craftsmanship being major factors.

Conclusion

Precision casting transforms holiday decoration and gifting into an art form. By combining high-precision manufacturing, material versatility, and efficient production, you can craft truly unique ornaments, keepsakes, and figurines that impress family, friends, and clients.

Whether creating a corporate gift, a custom ornament, or a collector’s figurine, investment casting ensures each piece embodies craftsmanship, durability, and aesthetic excellence—making the holiday season more special, memorable, and personalized than ever before.

FAQ

Q: What design files are required for custom gifts?

A: CAD files or compatible 3D models are necessary. Accepted formats include IGES (.igs), STEP (.stp), ACIS (.sat), or Parasolid (.x_t/.x_b). 2D drawings are generally insufficient for high-precision components.

Q: How quickly can I receive a prototype?

A: Silica sol casting prototypes typically require 20–30 days. Sand casting for larger, less precise components usually takes 7–10 days.

Q: Which materials are recommended for long-lasting holiday keepsakes?

A: Stainless Steel, Aluminum alloys, Copper alloys, Zinc alloys, and Titanium alloys are all suitable, depending on desired durability, finish, and visual effect.

Q: What if the sample does not meet expectations?

A: Samples are produced based on your drawings to confirm structure and quality. Free replacement is guaranteed until the sample meets specifications.

Q: Can investment casting handle multi-part or moving components?

A: Yes, complex assemblies can be cast as separate components and then assembled. This allows for movable figurines or interactive ornaments.

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF