Latest Insights on Ductile Iron Castings for Industry

Ductile iron castings, also known as nodular or spheroidal graphite iron, are widely used in modern industry for their strength, toughness, and cost-effectiveness. This article provides a structured overview of ductile iron, including its properties, manufacturing processes, applications, compliance standards, practical examples, and tips for selecting the right grade for specific applications.

Table of Contents

Understanding Ductile Iron

Definition and Characteristics

Ductile iron is a type of cast iron in which graphite appears as spherical nodules rather than flakes. This unique microstructure gives the material:

- High tensile strength

- Superior ductility

- Excellent impact and fatigue resistance

This combination allows ductile iron to withstand higher stresses and dynamic loads compared to traditional gray cast iron.

Importance in Modern Industry

Ductile iron castings are commonly used for:

- Automotive components: gears, suspension parts, crankshafts

- Industrial machinery: gear housings, machine frames

- Pipelines and valves for water and gas distribution

It balances performance and cost, making it ideal for large-scale production.

Key Properties of Ductile Iron

Mechanical Properties

Ductile iron’s mechanical characteristics vary by grade but generally include:

- Tensile Strength: 400–700 MPa

- Yield Strength: 250–500 MPa

- Elongation: 10–18%

These properties ensure that components made from ductile iron can bear heavy loads while resisting cracking or brittle failure.

Thermal and Corrosion Resistance

Ductile iron is stable at high temperatures and exhibits good chemical resistance, making it suitable for:

- Industrial pumps and valves handling corrosive fluids

- Pipelines exposed to a variety of chemicals

Impact and Fatigue Performance

The spheroidal graphite structure allows the material to absorb shocks and resist fatigue, which is crucial for automotive, heavy machinery, and rotating equipment applications.

Manufacturing Process

Melting and Alloying

The process starts with melting pig iron, scrap iron, and alloying elements such as magnesium or cerium, which promote graphite spheroidization.

Spheroidization

The formation of graphite nodules ensures:

- Uniform mechanical properties

- Reduced brittleness and cracking risk

Casting Methods

- Sand Casting: For large and complex shapes

- Investment Casting: For precision components

- Centrifugal Casting: For pipes and cylindrical components

Heat Treatment and Machining

Post-casting annealing or normalizing improves mechanical performance. Ductile iron is machinable, allowing precise dimensions and surface finishes.

Applications of Ductile Iron Castings

Ductile iron castings are versatile and widely adopted across automotive, water infrastructure, and industrial machinery due to their high strength, ductility, and cost-effectiveness. Its unique combination of mechanical performance and durability makes it ideal for components exposed to dynamic loads, corrosive environments, or high wear conditions.

Automotive Components

Ductile iron is extensively used in the automotive sector for parts that must withstand high stress and fatigue:

- Crankshafts: High tensile strength (up to 700 MPa) ensures durability under cyclic engine loads.

- Gears and Gear Housings: Excellent wear resistance supports long service life in transmission systems.

- Brake Discs and Rotors: High thermal stability and impact resistance reduce deformation and enhance braking performance.

- Suspension Components: Superior ductility provides shock absorption and prevents brittle failure under dynamic loads.

Case Study:

An automotive manufacturer replaced forged steel gears with ductile iron. Benefits included:

- 20% weight reduction for improved fuel efficiency

- Maintained fatigue performance under rigorous driving conditions

- 15% reduction in manufacturing costs due to lower material and machining expenses

Additional Insight: Ductile iron’s machinability and casting flexibility allow complex geometries, reducing the need for multi-part assemblies and additional welding or machining.

Pipes and Valves

Ductile iron is a preferred material for water, sewage, and gas pipelines due to its corrosion resistance, strength, and longevity:

- Water and Sewage Pipelines: Can withstand internal pressure up to 25 bar (depending on class), resistant to aggressive fluids.

- Gas Distribution Lines: Ductile iron’s toughness minimizes the risk of brittle fractures, ensuring safe delivery of natural gas.

- Valve Bodies and Pump Casings: Strong, machinable, and able to handle high-pressure operation in municipal and industrial systems.

Real Case:

A municipal water company replaced cast steel valves with ductile iron valves, achieving:

- 30% weight reduction for easier installation and reduced transport costs

- 10 years of maintenance-free operation, reducing lifecycle expenses

- Compliance with ASTM A536 standards and local regulatory requirements

Technical Note: Many modern ductile iron pipelines include polymer coatings or epoxy linings for enhanced corrosion resistance, particularly in areas with acidic or chlorinated water.

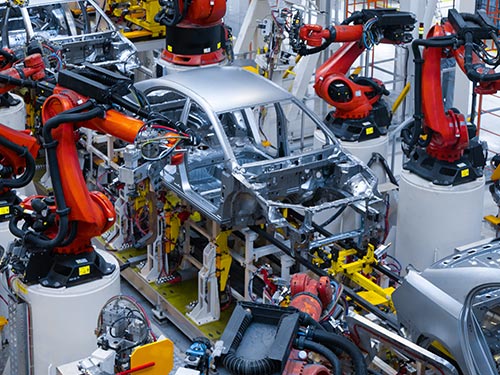

Industrial Machinery

Ductile iron is used for high-load, high-stress components in industrial machinery, where mechanical reliability is critical:

- Gear Housings and Casings: Resist fatigue from continuous operation in heavy-duty applications.

- Machine Frames: Stable under high vibration and dynamic loads, minimizing deflection.

- Pumps and Compressors: High impact resistance ensures longevity, even under pressure fluctuations.

- Industrial Rollers and Shafts: High tensile strength and wear resistance allow extended service intervals.

Case Example:

A manufacturing plant replaced gray iron machine frames with ductile iron castings:

- Reduced downtime by 25% due to fewer maintenance interruptions

- Lowered repair costs by 18%

- Improved safety and operational reliability

Additional Consideration: Ductile iron components can be heat-treated or surface-coated to further improve wear resistance and corrosion protection, making them suitable for chemical, mining, and heavy machinery application

Emerging and Specialized Applications

Beyond conventional uses, ductile iron is increasingly applied in high-tech and specialized fields:

- Renewable Energy: Components for wind turbines, such as hubs and gearboxes, leverage ductile iron’s fatigue resistance.

- Marine Applications: Pump housings, propeller shafts, and underwater valves benefit from corrosion-resistant grades.

- Aerospace Ground Equipment: Durable, high-strength ductile iron parts are used in landing gear testing rigs and support machinery.

Technical Insight: Modern ductile iron alloys with controlled alloying elements (e.g., Ni, Cu, Mo) can achieve higher tensile strength and hardness, bridging the performance gap with lower-cost steel alternatives.

Performance Comparison

| Property | Ductile Iron | Gray Iron | Cast Steel |

|---|---|---|---|

| Tensile Strength | 400–700 MPa | 200–400 MPa | 500–800 MPa |

| Yield Strength | 250–500 MPa | 150–250 MPa | 350–600 MPa |

| Elongation | 10–18% | 1–3% | 15–25% |

| Impact Resistance | High | Low | High |

| Wear Resistance | Good | Moderate | Excellent |

| Cost | Moderate | Low | High |

| Machinability | Good | Excellent | Moderate |

Insight: Ductile iron offers balanced performance, bridging the gap between gray iron and steel for cost-sensitive, high-performance applications.

Standards and Quality Compliance

International Standards

- ASTM A536: Defines chemical composition and mechanical properties for different grades

- ISO 1083: Specifies classification and mechanical testing methods for nodular cast iron

Quality Control

- Non-destructive Testing (NDT): Ultrasonic or radiographic inspections

- Chemical Analysis: Confirms proper alloy composition

- Surface Inspection: Detects porosity or shrinkage defects

Case Example:

A European valve manufacturer used CMM and ultrasonic testing to meet EU dimensional and mechanical standards, reducing scrap rate by 15%.

Common Challenges and Solutions

Porosity and Shrinkage

- Cause: Improper cooling or mold design

- Solution: Optimize gating system and controlled solidification

Machining Difficulties

- Cause: Ductile iron hardness

- Solution: High-speed tooling, lubrication, and feed rate adjustments

Corrosion and Wear

Surface treatments such as nitriding, epoxy coating, or galvanizing can extend service life in harsh environments

Future Trends in Ductile Iron Castings

- High-strength, lightweight alloys for automotive and aerospace

- Smart manufacturing with AI-assisted process control

- Sustainable production using recycled scrap and lower energy consumption

FAQ

What is the difference between ductile iron and gray iron?

Ductile iron has spherical graphite, providing higher strength and ductility; gray iron has flake graphite and is brittle.

How strong are ductile iron castings?

Tensile strength ranges 400–700 MPa, depending on grade and heat treatment.

What are common applications?

Automotive parts, valves, pipes, and machinery frames.

How is ductile iron manufactured?

Through melting, spheroidization, casting, and heat treatment for uniform properties.

Which standards apply?

ASTM A536 and ISO 1083.

How to prevent defects?

Control furnace parameters, alloy composition, mold design, and cooling.

Can ductile iron replace steel?

Yes, where high strength, toughness, and cost-efficiency are needed.

Are ductile iron castings recyclable?

Yes, making them environmentally sustainable.

How do I choose the right grade?

Consider tensile strength, elongation, fatigue resistance, and application requirements.

Are ductile iron valves better than steel valves?

Ductile iron valves offer weight reduction, corrosion resistance, and cost savings while maintaining performance.

Need Customized Ductile Iron Castings?

Our engineering team provides tailored solutions for automotive, industrial, and municipal projects.

Contact our engineers today to discuss specifications, compliance, and optimization for your next project.

Stay Connected with Us

Thank you for reading! We hope this blog provided you with valuable insights and inspiration on acoustic panel ceilings. If you enjoyed the content and want to stay updated with the latest trends, tips, and behind-the-scenes updates, we’d love to connect with you on social media.

📘 Follow us on Facebook: Shanghai Leierwo Industry Trade Co., Ltd.

Join our growing community where we share expert advice, product highlights, and interactive discussions with professionals and design enthusiasts from around the world.

Let’s keep the conversation going—see you there!

Product Categories

- Valve Parts

- Water Pump Parts

- Bearing Box Parts

- Die Casting Parts

- Stainless Steel Pump Products

- Cast Iron Pump Products

- Valve Parts For Automobile Use

- Auto Parts

- Valve Parts For Civil Use

- Vacuum Pump Parts KF