Forging

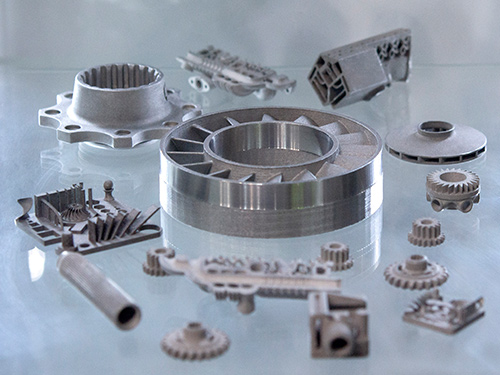

Shanghai Leierwo’s forging mass production service is tailored for customers who pursue excellent mechanical properties, ultra-high strength and durability.

The forging process utilizes immense pressure to plastically deform a metal blank, rather than melting it. This allows the metal’s internal fibers to align continuously along the principal stress directions, resulting in parts with strength, impact resistance, and fatigue life far exceeding those of castings.

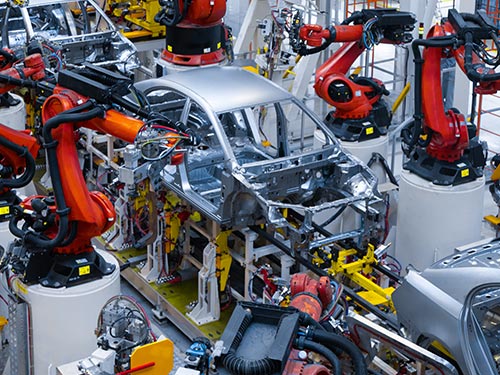

Unlike casting and welding, forging aims to optimize the material’s inherent structure and physical properties. Our services are ideal for industries with stringent safety and durability requirements, such as automotive, aerospace, and heavy machinery. We offer flexible, customized production adjustments, ranging from single-piece, small-batch production to large-scale assembly line production, to meet diverse global market demands.

Unlike casting and welding, forging aims to optimize the material’s inherent structure and physical properties. Our services are ideal for industries with stringent safety and durability requirements, such as automotive, aerospace, and heavy machinery. We offer flexible, customized production adjustments, ranging from single-piece, small-batch production to large-scale assembly line production, to meet diverse global market demands.

Our Core Forging Capabilities

We specialize in enhancing the mechanical properties of parts by controlling the grain flow of metals and provide high-reliability mass production services:

| Core Competencies | Description and Advantages |

| Excellent Mechanical Properties | Through the plastic deformation process, the parts have an optimized grain structure and higher density, ensuring excellent strength, toughness and fatigue resistance. |

| High Standard Quality System | We strictly adhere to ISO 9001:2015 and IATF 16949:2016 certifications to fully meet the stringent requirements of the automotive industry for component performance and quality control. |

| Flexible Batch Production | With a flexible production model, it can be customized on demand and supports the entire process from design optimization to large-scale delivery. |

| Experience and Design Optimization | With over 18/20 years of experience in metal fabrication, he is able to redesign parts to perfectly suit the forging production process and recommend the optimal manufacturing process. |

Wide Range Of Applications And Core Products

Forgings are essential, high-stress components in many critical industrial and transportation sectors. We primarily serve industries that demand safety, precision, and durability, leveraging advanced Forging technology.

Auto Industry:

It is suitable for manufacturing key components with high requirements on fatigue life, such as engine parts, transmission parts and brake system parts.

Industrial Coupling Manufacturing:

Elastic/rigid couplings, diaphragm/gear couplings can be customized, and forging ensures the strength and durability of these transmission parts.

Flange Manufacturing:

The production of welding flanges, butt-welding flanges, etc. The dense forging structure can ensure its sealing and safety in high-pressure pipelines.

General Mechanical Parts:

Forging is suitable for general and specialized mechanical components, including machine tools and industrial robots, providing the high-strength required for demanding applications.

How The Production Process Works

We want to make working with us on a production project as smooth and streamlined as possible.

1

Speak with a manufacturing expert who will help you customize your production quote around a complete bill of materials.

2

Work with our team to optimize your project for production, including design for manufacturability and cost reduction options.

3

An initial sample run of the part is manufactured and sent to you to ensure the part meets your standards before full production begins.

4

Gain process transparency and quality control when full production begins.

5

Apply post-processing and final quality measures before parts are shipped.

6

Place subsequent batch production orders for your project at any time through our virtual warehouse.

Start Your Project with Leierwo

1. Submit Your Inquiry

Send your CAD drawings and 3D files via email, specifying material grade, order quantity, surface finish, or any other relevant details.

2. Cost Calculation

Once we receive your design, our engineering team will carefully evaluate the drawings and calculate the price based on actual production costs as soon as possible.

3. Start Production

Upon pricing approval, our production team will prepare the materials and schedule production promptly. Leierwo always ensures on-time delivery.

4. Arrange Delivery

After production is completed, we will provide packaging details and arrange shipment via sea or air. We support global shipping for every order.

FAQ

Q1. Are you a trading company or a manufacturer?

Q2. Can you quote based on 3D drawings?

Q3. How do you handle RFQs (Request for Quotation)?

Q4. What is your typical lead time?

Q5. Do you provide samples? Are they free?

Q6. What payment methods do you accept?

Q7. How do you ensure quality control?

Q8. Do your products come with a warranty?

Q9. How do you view your relationship with customers?